Stainless Steel Sheet ASTM Standard 200,300,400 Series

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Stainless Steel Sheet Description

The surface brightness and flatness of no2B is better than no2D. then through a special

surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses.

2.Main Features of the Stainless Steel Sheet

• Decoration

• Daily Necessities

•,Medical Treatment

• Daily Necessities

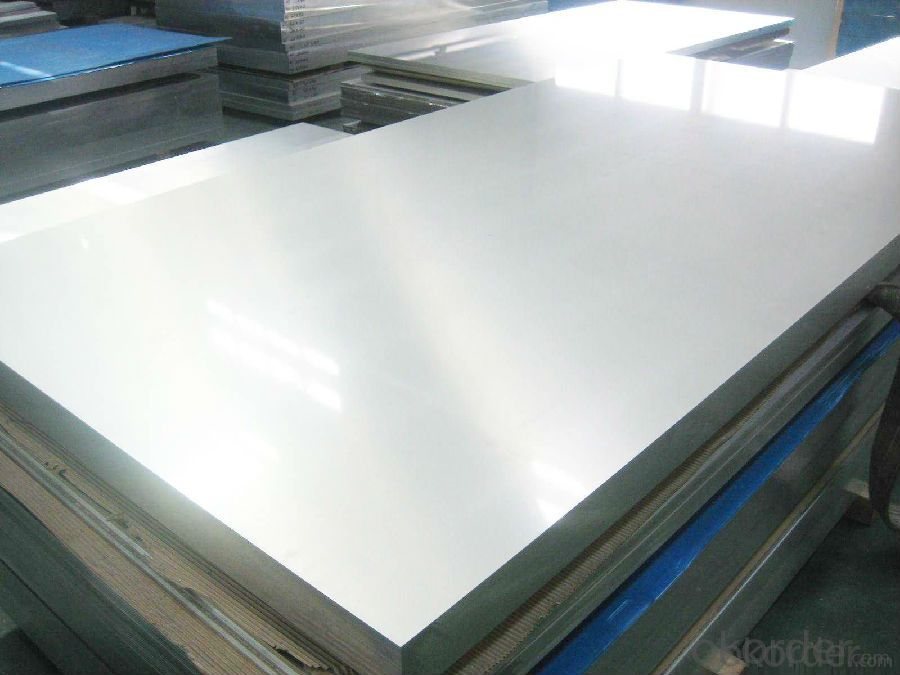

3. Stainless Steel Sheet Images

4. Stainless Steel Sheet Specification

Grade: | 200,300,400 Series Stainless Steel Sheet | Standard: | JIS,AISI,ASTM,GB,DIN,EN | Length: | 0-6000mm ,Or According to clients' requirement

|

Thickness: | 0.3mm-100mm | Width: | 10mm-2500mm | Place of Origin: | Shanxi China (Mainland) |

Brand Name: | CNBM | Model Number: | 200,300,400 Series,200,300,400 Series Stainless Steel Sheet

| Type: | Plate |

Application: | Decoration, Machinerhty,Lig Industry,Heavy Industry,Daily Necessities,Decoration,Kitchen,Building,Medical Treatment,Transport,Chemical

| Certification: | SGS,ISO,SGS | Technique: | Cold/hot rolled |

Surface Finish: | 2B,NO.1,NO.3,NO.4,HL,BA,8K,mirror,polished etc. | Exported Area: | USA,Europe,Asia,Middle East,Africa,South America | Packaging: | As Customers Requirement |

5.FAQ of Stainless Steel Sheet

①Who are you?

We are the manufacturer! We produce stainless steel products

with high quality & very competitive price!Please feel free to

contact us for more information!

②How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

③How about your company?

A world class manufacturer & supplier of castings forging in Stainless Steel Sheet,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

- Q:How are steel strips used in the production of metal roofing?

- Steel strips are an essential component in the production of metal roofing. These strips are typically made from high-quality steel, which is known for its strength, durability, and resistance to corrosion. In the manufacturing process, the steel strips are first rolled into coils of varying widths and thicknesses. These coils are then unwound and fed into a series of machines that shape and form them into the desired roofing profiles. The strips may undergo processes such as cutting, bending, and corrugating to achieve the desired shape and strength. One of the key advantages of using steel strips in metal roofing production is their ability to provide structural integrity and stability to the final product. Steel is known for its high tensile strength, which allows metal roofs to withstand harsh weather conditions, such as strong winds, heavy rains, and even hailstorms. Additionally, steel strips can be coated with various protective finishes, such as galvanized or coated with zinc or aluminum, to enhance their resistance to corrosion. These coatings create a barrier that prevents moisture from seeping into the steel and causing rust, extending the lifespan of the metal roof. Moreover, steel strips offer versatility in terms of design options for metal roofing. They can be manufactured in a wide range of colors, textures, and profiles, allowing homeowners and builders to choose a metal roof that complements the overall aesthetics of a building. The ability to create different shapes and profiles also enables the production of metal roofing that can mimic the appearance of traditional roofing materials, such as shingles or tiles. In summary, steel strips play a crucial role in the production of metal roofing by providing strength, durability, resistance to corrosion, and design flexibility. These strips are transformed into various roofing profiles, ensuring that metal roofs can withstand harsh weather conditions while offering an attractive and long-lasting roofing solution.

- Q:How are steel strips produced?

- Steel strips are produced through a process called hot rolling, where a steel slab is heated and then passed through a series of rolling mills to reduce its thickness and shape it into a strip.

- Q:How are steel strips slit into narrower widths?

- The process of slitting involves cutting steel strips into narrower widths. This is achieved by using a machine known as a slitter, which is outfitted with circular blades. When the steel strip is introduced into the slitter, the circular blades begin to rotate and slice the strip into narrower widths. The number and positioning of the blades can be adjusted based on the desired final width of the product. To ensure precision and accuracy, the slitter is equipped with different mechanisms, including tension control systems and edge guides. These mechanisms work together to maintain the proper tension on the strip and ensure it remains aligned throughout the slitting process. Once the strip has been cut into narrower widths, each individual coil or strip is then rewound onto separate spools or coils. These narrower strips can be utilized in a variety of applications, such as manufacturing automotive parts, appliances, construction materials, and other steel products.

- Q:How do steel strips respond to different surface treatment processes?

- Steel strips respond differently to different surface treatment processes depending on the specific treatment method used. Some common surface treatment processes for steel strips include galvanizing, painting, electroplating, and powder coating. Galvanizing involves coating the steel strips with a layer of zinc, which provides protection against corrosion. This process is known to significantly enhance the durability and longevity of the steel strips, making them more resistant to rust and other forms of deterioration. Painting steel strips involves applying a layer of paint onto the surface, which not only enhances the aesthetic appearance but also provides a protective barrier against corrosion. The type of paint used can vary depending on the specific application and environmental conditions the steel strips will be exposed to. Electroplating is a process that involves depositing a thin layer of metal onto the steel strips through an electrochemical reaction. This can enhance the appearance, corrosion resistance, hardness, and conductivity of the steel strips, depending on the metal used for plating. Powder coating is a technique that involves applying a dry powder to the surface of the steel strips, which is then cured under heat to form a protective layer. This process provides excellent resistance against corrosion, chemicals, UV rays, and abrasion, making it a popular choice for various applications. In summary, different surface treatment processes for steel strips provide different benefits and characteristics. Galvanizing and painting offer protection against corrosion, electroplating enhances various properties, and powder coating provides excellent resistance to various environmental factors. The choice of the surface treatment process depends on the specific requirements and intended use of the steel strips.

- Q:How do you calculate the weight of a steel strip?

- To calculate the weight of a steel strip, you need to know its length, width, and thickness. The formula for calculating weight is weight = length x width x thickness x density of steel. By inputting these values and the density of steel, you can determine the weight of the steel strip.

- Q:Can steel strips be used for making agricultural machinery?

- Yes, steel strips can be used for making agricultural machinery. Steel strips provide strength, durability, and resistance to wear and tear, making them ideal for manufacturing various components of agricultural machinery such as blades, plows, cultivators, and harrows. Additionally, steel strips can be easily shaped and welded to create custom designs, allowing for the efficient production of agricultural equipment.

- Q:How are steel strips welded?

- Steel strips can be welded using a variety of welding techniques, depending on the specific application and desired outcome. One common method is known as arc welding, which involves the use of an electric current to create an arc between the steel strips and a welding electrode. This generates intense heat, melting the edges of the strips, and allowing them to fuse together. Another method is known as resistance welding, which involves passing an electrical current through the steel strips, creating heat at the point of contact. The strips are then pressed together, creating a strong bond as the heat melts the edges and fuses them together. Laser welding is another technique used to weld steel strips. In this method, a high-powered laser beam is used to melt and fuse the edges of the strips together. Laser welding offers high precision and can be used for a wide range of steel strip thicknesses. Additionally, there are other welding methods such as gas welding, friction welding, and ultrasonic welding that can also be used depending on the specific requirements and constraints of the project. Regardless of the welding technique used, it is important to ensure proper preparation of the steel strips, including cleaning and removal of any contaminants, to achieve a strong and durable weld. Welding parameters such as heat input, travel speed, and electrode selection should also be carefully controlled to ensure a quality weld with minimal distortion and maximum strength.

- Q:Are steel strips suitable for the production of agricultural equipment?

- Yes, steel strips are suitable for the production of agricultural equipment. Steel is a durable and strong material that can withstand the harsh conditions and heavy usage often associated with agricultural equipment. It provides stability, resilience, and longevity, making it an ideal choice for manufacturing various agricultural machinery and implements.

- Q:What are the standard dimensions of steel strips?

- The standard dimensions of steel strips can vary depending on the specific application and industry. However, common standard dimensions for steel strips range from widths of 0.5 inches to 36 inches and thicknesses of 0.001 inches to 0.5 inches.

- Q:How are steel strips tested for internal defects?

- Steel strips are typically tested for internal defects using non-destructive testing methods such as ultrasonic testing or magnetic particle inspection. These techniques involve the use of specialized equipment to detect and analyze any internal flaws or irregularities in the steel strips without causing any damage to the material.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel Sheet ASTM Standard 200,300,400 Series

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords