Stainless Steel Plate Sheet in Bulk Sale

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

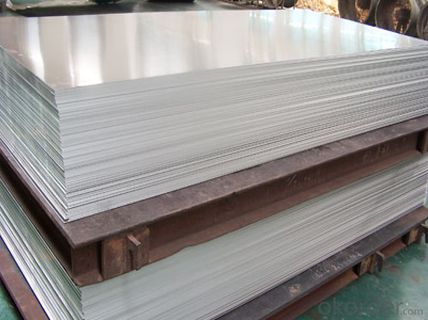

Stainless Steel Plate Sheet in Bulk Sale

Product Description

Description | steel sheet,hot rolled steel sheet,cold rolled stainless steel sheet, steel sheet,sheet,steel plate |

Material | 201,202,304,304L,309S,310S,316,316L,316Ti,317L,321,347H,409,409L,410,410S,420,430,etc. |

Thickness | From 0.3mm to 100mm |

Width | 1000mm,1219mm,1250mm,1500mm,1800mm,2200mm or be cut as your requirement |

Length | 2000mm,2438mm,2500mm,6000mm,6096mm or be cut as your requirement |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | By bulk vessel OR By container OR as customers' requirement |

Delivery time | 2-3 weeks after reciept the L/C OR T/T |

Quality | No.1 |

Productivity | 1000 tons/mouth |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

FAQ

Q: Why should you choose us:

A: 1. More than 10 years experience in this industry

2. 100,000 tons exporting per month

3. Professional foreign trade tea

4. OEM&ODM capacity

5. High quality assured & competitive price

6. Try our best to meet your needs & save your budget

7. Very popular in Southeast Asia, Africa, Mid-East and South America etc.

8. VIP membership system, first time customers and long-term cooperation customers can get extra discount on some products.

Advantages

Provide one-step purchase service to save your time, money and energy

Competive price, superior quality,and excellent logistics arrangement

Complete production line to provide full set products

Experienced facotry specialize in Building material

Professional Service team

Picture

- Q:How is stainless steel wire manufactured?

- Wire drawing is the method utilized to manufacture stainless steel wire. This technique comprises pulling a stainless steel rod or billet through a succession of dies to decrease its diameter and increase its length. To commence the manufacturing process, the appropriate grade of stainless steel must be chosen, which may differ depending on the desired wire properties. The most common grades are 304, 316, and 430 stainless steel, each possessing distinct compositions and characteristics. Once the stainless steel rod or billet is selected, it undergoes a cleaning and lubrication process to facilitate the wire drawing. This aids in reducing friction and heat generation during the drawing operation. The subsequent step involves passing the stainless steel rod or billet through a series of dies, usually made of tungsten carbide or diamond. These materials possess extreme hardness, allowing them to shape the stainless steel without causing excessive wear. Each die in the series has a slightly smaller diameter than the previous one, resulting in the stainless steel being drawn through progressively smaller openings. As the stainless steel passes through each die, its diameter decreases and its length increases. This process is repeated several times until the desired diameter and length of wire are achieved. Throughout the wire drawing process, the stainless steel wire is periodically annealed to relieve internal stresses and enhance its ductility. Annealing involves heating the wire to a specific temperature and then slowly cooling it. This process improves the wire's mechanical properties and makes it easier to work with. Once the stainless steel wire reaches the desired diameter, it undergoes further processing to eliminate any surface defects or imperfections. Typically, this is accomplished through pickling, which involves immersing the wire in an acid solution to remove any oxide layers or scale that may have formed during manufacturing. Following pickling, the stainless steel wire may undergo additional processes such as coating or heat treatment, depending on its intended application. These processes can further enhance the wire's corrosion resistance, strength, or other desired properties. Upon completion of the manufacturing process, the stainless steel wire is typically wound onto spools or reels for storage and transportation. It can then be utilized in various applications, such as construction, automotive, or industrial purposes. In summary, the manufacturing of stainless steel wire combines precision engineering, material selection, and various processing techniques to produce a versatile and high-quality product.

- Q:Stainless steel screws and steel screws, that kind of hardness?

- In terms of strength aloneCarbon steel is stifferCan go to level 12.9Stainless steel is better in corrosion resistance and acid resistance

- Q:Fracture analysis of stainless steel screw

- Process problems in producing stainless steel screws. For example, stainless steel screw slant eccentric, as well as the production of manufacturing operations when the Q value is too deep down and R bit design is too small.

- Q:What are the different diameter tolerance options available for stainless steel wire?

- The diameter tolerance options for stainless steel wire can vary depending on the specific requirements of the application. In general, the standard tolerance is ±0.001 inches or ±0.0254 millimeters for stainless steel wire. However, there are also tighter tolerance options available for more precise applications. These tighter tolerances can range from ±0.0005 inches to ±0.0001 inches or ±0.0127 to ±0.00254 millimeters. It is worth noting that the diameter tolerance can also be specified as a percentage. For example, a tolerance of ±2% means that the actual diameter of the stainless steel wire can vary by up to 2% from the specified diameter. When choosing the appropriate diameter tolerance for stainless steel wire, it is important to consider the specific requirements of the application, including the intended use, environmental conditions, and desired level of precision. Seeking advice from a knowledgeable supplier or manufacturer can assist in determining the most suitable diameter tolerance option for a particular stainless steel wire application.

- Q:What are the different types of stainless steel wire rope coatings available?

- There is a wide range of coatings available for stainless steel wire ropes, each with its own unique properties and advantages. Some of the most commonly used coatings are as follows: 1. Vinyl Coating: This coating is highly popular for stainless steel wire ropes due to its excellent resistance against corrosion, abrasion, and weathering. Additionally, it comes in various colors, which aids in identification and organization. 2. Nylon Coating: Similar to vinyl coating, nylon coating offers comparable benefits but with added strength and durability. It provides enhanced resistance against abrasion and is typically utilized in applications that require extra protection against wear and tear. 3. Polyethylene Coating: Renowned for its exceptional resistance to chemicals, moisture, and UV radiation, this coating is commonly employed in marine environments or areas exposed to severe weather conditions. 4. Epoxy Coating: Epoxy coatings deliver superior protection against corrosion and can endure extreme temperatures. They are often applied in industrial settings where wires may come into contact with chemicals, oils, or solvents. 5. Galvanized Coating: Although not technically a stainless steel wire rope coating, galvanization involves applying a layer of zinc to the wire rope's surface for protection against rust and corrosion. This coating is frequently utilized in outdoor and marine applications. When selecting a coating for your stainless steel wire rope, it is crucial to consider the specific requirements of your application. Factors like environmental conditions, exposure to chemicals or moisture, and desired durability will help determine the most suitable coating option for your needs.

- Q:Is stainless steel wire suitable for wire rope end fittings?

- Yes, stainless steel wire is suitable for wire rope end fittings. Stainless steel is known for its excellent corrosion resistance and strength, making it a reliable choice for wire rope end fittings that require durability and longevity.

- Q:Can stainless steel wire be used for filtration purposes?

- Yes, stainless steel wire can be used for filtration purposes. It is commonly used in applications requiring high strength and resistance to corrosion, making it suitable for filtering liquids and gases in various industries such as pharmaceutical, food processing, and wastewater treatment. The wire's durability and ability to withstand high temperatures and pressure make it an effective choice for filtration systems.

- Q:Is stainless steel wire suitable for wire rope sheaves?

- Yes, stainless steel wire is suitable for wire rope sheaves. Stainless steel is known for its corrosion resistance and durability, making it a suitable choice for applications where the wire rope sheaves may be exposed to harsh environments or corrosive substances. Additionally, stainless steel wire has high tensile strength, allowing it to withstand heavy loads and provide reliable performance.

- Q:Can stainless steel wire be used for making wire racks?

- Yes, stainless steel wire can be used for making wire racks. Stainless steel is a durable and corrosion-resistant material, making it suitable for various applications, including wire racks.

- Q:Stainless steel screws do not move

- Several possible causes and countermeasures:1. may the glue used in the tightening of the time, so, you can try to use firearms to burn out, see no smoking;2., there is the thread has been damaged, embedded in aluminum, in this case, there is no good way, you can leverage the principle of lengthening the arm, find the extension with the steel pipe to try;

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel Plate Sheet in Bulk Sale

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords