Stainless Steel Plate 444 with Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Stainless Steel Plate 444 with Surface Treatment

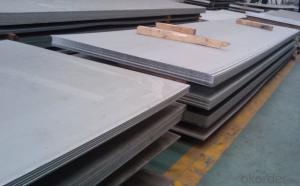

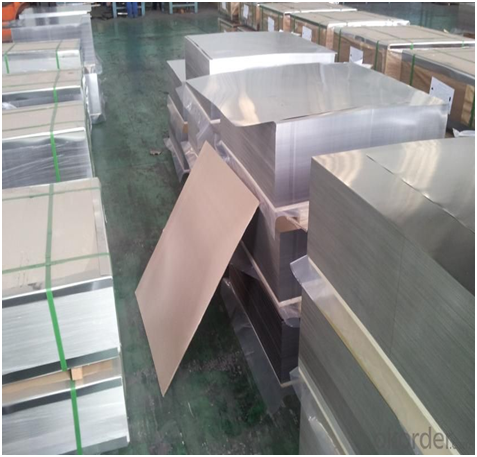

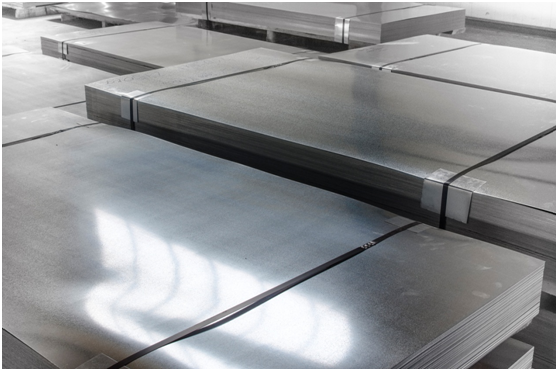

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Material |

201/202,304/304L, 310S/309S/316L/316Ti/321,410/420/430/444/443/409L, and 904L

|

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

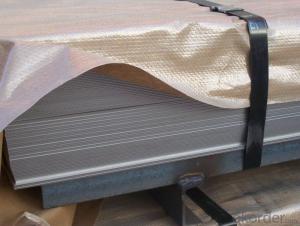

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

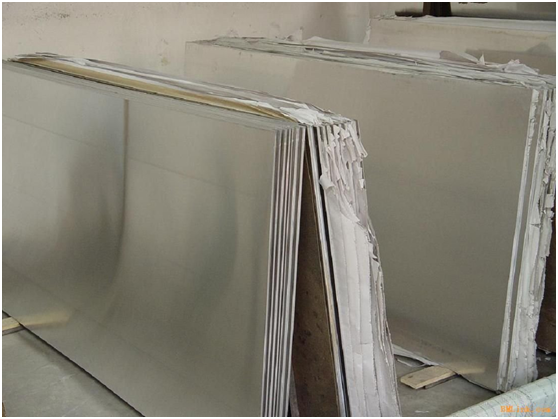

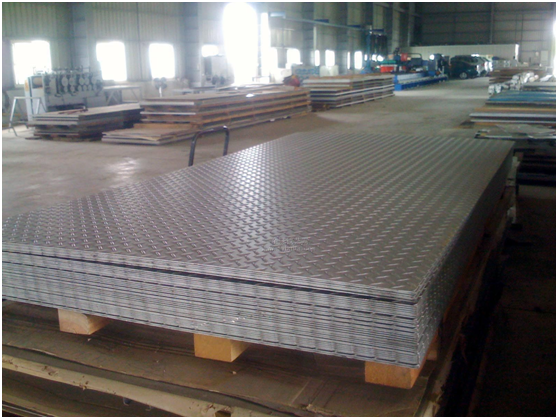

Cold Rolled and Hot Rolled:

Packaging & Shipping

Our Services

Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured.

Company Information

CNBM(China National Building Material Company)International Corporation is a state owned Enterprise.

We are listed in the fortune global 500 companies, and we are the second largest building material company in the world.

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a prelonged period. We are currently doing grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321,410/420/430/444/443/409L, and 904L.

FAQ

1. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

2. How long do we usually reply your request?

We always reply our customer within 24 hours.

3. What material are we supplying now?

We are specialized in producing Stainless Steel Coil, Stainless steel(plate/sheet), and duplex stainless steel for 2 decades. We are currently supplying 201/202, 304/304l, 310S/309S/316l/316Ti/321, 410/420/430/444/443/409l, and 904l.

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q:How can I classify stainless steel plates?

- Stainless steel plate steel according to the histological classification, can be divided into: Austenitic (200 series, 300 series stainless steel), austenite ferrite (both austenite and ferrite stainless steel body) and ferrite (409, 430, 434 series stainless steel) and martensite (403, 410, 414, 416.).

- Q:Can stainless steel sheets be used for soundproofing?

- Stainless steel sheets alone are not typically used for soundproofing purposes. While stainless steel is known for its durability and corrosion resistance, it does not possess significant soundproofing properties. However, stainless steel sheets can be incorporated into soundproofing systems as part of a composite structure or in conjunction with other soundproofing materials to enhance their overall effectiveness.

- Q:Can stainless steel sheets be used for HVAC systems?

- Yes, stainless steel sheets can be used for HVAC systems. Stainless steel is highly resistant to corrosion and can withstand high temperatures, making it an ideal material for HVAC components such as ductwork, heat exchangers, and exhaust systems. It is also durable and easy to clean, ensuring long-lasting performance in HVAC applications.

- Q:Can stainless steel sheets be used for restaurant equipment?

- Certainly! Restaurant equipment can indeed utilize stainless steel sheets. Stainless steel is a highly favored option for restaurant equipment owing to its multitude of advantages. Its durability, resistance to corrosion, and ease of cleaning all contribute to its popularity. By employing stainless steel sheets, restaurant equipment can be crafted into diverse forms and dimensions, fulfilling the particular needs of countertops, sinks, tables, shelves, and food preparation surfaces. Moreover, stainless steel is an exceptionally hygienic substance that does not interact with food or taint it, rendering it perfect for deployment in restaurant environments where cleanliness and food safety are of utmost importance.

- Q:Can stainless steel sheets be used for medical equipment?

- Indeed, medical equipment can utilize stainless steel sheets. The medical industry extensively employs stainless steel due to its remarkable resistance to corrosion, its durability, and its ease of cleaning. Surgical instruments, implants, medical devices, and equipment like sterilization trays, hospital beds, and operating room tables are commonly manufactured using stainless steel. As it does not react with bodily tissues or fluids, stainless steel is a secure and sanitary option for medical purposes. Moreover, it can endure numerous sterilization procedures without compromising its qualities, thus rendering it perfectly suited for hospitals and healthcare facilities.

- Q:What is the machinability of stainless steel sheets?

- The machinability of stainless steel sheets can vary depending on the grade of stainless steel and its specific composition. Generally, stainless steel is known to have lower machinability compared to other types of metals such as carbon steel or aluminum. This is mainly due to its higher strength, hardness, and work-hardening characteristics. Stainless steel has a tendency to work-harden during machining, leading to increased cutting forces and tool wear. It also has a lower thermal conductivity, which can result in higher temperatures during machining operations, further contributing to tool wear. Additionally, stainless steel has a unique chip formation behavior, often resulting in stringy and difficult-to-break chips. However, advancements in cutting tool technology and machining techniques have made it possible to improve the machinability of stainless steel. For instance, using appropriate cutting tool geometries, coatings, and coolant/lubricant can help reduce cutting forces, minimize tool wear, and improve chip control. It is important to note that different grades of stainless steel can exhibit varying machinability. Austenitic stainless steels, such as 304 and 316, are generally more difficult to machine compared to ferritic or martensitic stainless steels. This is due to their higher nickel and chromium content, which contribute to their superior corrosion resistance but also make them harder to machine. Overall, while stainless steel sheets may present some challenges in machining, with the right tools, techniques, and experience, it is possible to achieve satisfactory machinability and produce high-quality components from stainless steel sheets.

- Q:What are the advantages of using stainless steel sheets in the aerospace industry?

- There are several advantages of using stainless steel sheets in the aerospace industry. Firstly, stainless steel is known for its exceptional strength and durability. It can withstand high temperatures and extreme conditions, making it ideal for aircraft components that require superior performance and longevity. This strength allows stainless steel sheets to resist corrosion, which is crucial in an industry where safety is of utmost importance. Secondly, stainless steel sheets offer excellent resistance to impact and fatigue. This is particularly vital in the aerospace industry, where components are subjected to constant vibrations and stress. Stainless steel can absorb these forces without compromising its structural integrity, ensuring the safety and reliability of the aircraft. Thirdly, stainless steel sheets have a high strength-to-weight ratio, making them lightweight yet strong. This is crucial in aviation, where reducing weight is a primary concern for fuel efficiency and overall performance. By using stainless steel sheets, aircraft manufacturers can achieve the desired strength without adding unnecessary weight, contributing to improved fuel economy and increased payload capacity. Furthermore, stainless steel sheets are highly versatile. They can be easily formed, welded, and machined into complex shapes and sizes, allowing for the production of intricate aerospace components. This versatility enables engineers to design and manufacture innovative aircraft parts, leading to improved aerodynamics, reduced drag, and enhanced overall performance. Lastly, stainless steel sheets have excellent heat resistance properties. They can withstand high temperatures without losing their strength or shape, making them suitable for applications that involve exposure to extreme heat, such as jet engines or exhaust systems. This heat resistance ensures the longevity and reliability of these critical components, contributing to the overall safety and efficiency of aircraft. In conclusion, the advantages of using stainless steel sheets in the aerospace industry are their exceptional strength and durability, resistance to impact and fatigue, high strength-to-weight ratio, versatility in manufacturing complex components, and excellent heat resistance properties. These qualities make stainless steel sheets an ideal choice for aircraft manufacturers, ensuring the safety, reliability, and efficiency of aerospace vehicles.

- Q:Are stainless steel sheets suitable for decorative purposes?

- Yes, stainless steel sheets are suitable for decorative purposes. Stainless steel has a sleek and modern appearance that adds a touch of elegance and sophistication to any space. Its smooth and reflective surface creates a visually pleasing aesthetic that enhances the overall look and feel of a room. Additionally, stainless steel is highly durable and resistant to corrosion, making it a long-lasting choice for decorative applications. The versatility of stainless steel sheets allows them to be used in various decorative forms, such as wall panels, backsplashes, countertops, and even furniture. Whether in residential or commercial settings, stainless steel sheets can be utilized to create stunning and eye-catching decorative elements that complement any interior design style.

- Q:Are stainless steel sheets resistant to erosion corrosion?

- Yes, stainless steel sheets are highly resistant to erosion corrosion. This is primarily due to the presence of chromium in the alloy, which forms a protective layer of chromium oxide on the surface of the steel. This layer acts as a barrier, preventing oxygen and moisture from reaching the underlying metal and thus protecting it from corrosion. Furthermore, stainless steel sheets are also resistant to erosion corrosion caused by various chemicals and acids. The alloy composition of stainless steel, which typically includes elements such as nickel and molybdenum, enhances its resistance to corrosion in harsh environments. This makes stainless steel sheets suitable for a wide range of applications, including in industries such as chemical processing, oil and gas, and marine. However, it is important to note that the resistance of stainless steel sheets to erosion corrosion can vary depending on the specific grade or alloy used. Different grades may have different levels of corrosion resistance, so it is essential to choose the appropriate grade based on the specific environmental conditions and requirements of the application. Regular maintenance and proper handling can also help prolong the lifespan and maintain the corrosion resistance of stainless steel sheets.

- Q:Can stainless steel sheets be used for elevator floors?

- Indeed, elevator floors can indeed make use of stainless steel sheets. Known for its durability and resistance to corrosion, stainless steel is widely employed in numerous fields, including elevator interiors. Elevator floors adorned with stainless steel sheets exude a sophisticated and contemporary aesthetic, all while effectively withstanding scratches, blemishes, and impacts. Moreover, stainless steel's effortless cleanliness and maintenance make it an ideal selection for elevator floors that endure substantial foot traffic.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel Plate 444 with Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords