Stainless Steel Plate 316Ti with Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

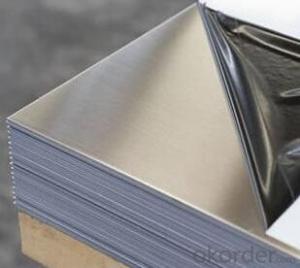

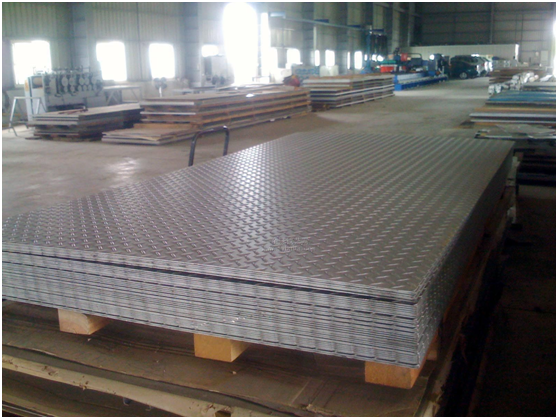

Stainless Steel Plate 316Ti with Surface Treatment

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Material |

201/202,304/304L, 310S/309S/316L/316Ti/321,410/420/430/444/443/409L, and 904L

|

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Cold Rolled and Hot Rolled:

Packaging & Shipping

Our Services

Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured.

Company Information

CNBM(China National Building Material Company)International Corporation is a state owned Enterprise.

We are listed in the fortune global 500 companies, and we are the second largest building material company in the world.

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a prelonged period. We are currently doing grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321,410/420/430/444/443/409L, and 904L.

FAQ

1. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

2. How long do we usually reply your request?

We always reply our customer within 24 hours.

3. What material are we supplying now?

We are specialized in producing Stainless Steel Coil, Stainless steel(plate/sheet), and duplex stainless steel for 2 decades. We are currently supplying 201/202, 304/304l, 310S/309S/316l/316Ti/321, 410/420/430/444/443/409l, and 904l.

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q:Can stainless steel sheets be used for soundproofing?

- Yes, stainless steel sheets can be used for soundproofing to a certain extent. While stainless steel itself is not a soundproofing material, it can be used as part of a soundproofing system. Stainless steel sheets can be installed as a barrier to block or reflect sound waves, reducing the amount of noise that passes through. However, for effective soundproofing, additional materials such as acoustic insulation and mass-loaded vinyl are typically used in conjunction with stainless steel sheets.

- Q:What are the different types of edge profiles for stainless steel sheets?

- Stainless steel sheets can be enhanced with various edge profiles to meet both aesthetic and functional needs. The following are a selection of these profiles: 1. The Square Edge: This is the simplest and most common profile, featuring a straight, unadorned edge. 2. The Beveled Edge: By angling and shaping the edge, a beveled profile adds a refined and polished look with a slight slope or chamfer. 3. The Rounded Edge: Also known as the bullnose edge, this profile smooths out sharp corners, reducing the risk of injury and creating a curved and sleek appearance. 4. The Full Radius Edge: This profile involves a complete semicircular or rounded edge, offering a more pronounced curved effect compared to the rounded edge. 5. The Ogee Edge: With a double curve of concave and convex shapes, the ogee edge adds an elegant and decorative touch, perfect for applications requiring a more ornamental appearance. 6. The Dupont Edge: This sleek and modern profile features a straight edge with small bevels on the top and bottom sides, often used in contemporary design applications. 7. The Knife Edge: By sharpening the edge to a thin, precise edge, the knife edge profile is ideal for applications requiring a clean-cut and precise appearance. These examples provide just a glimpse of the edge profiles available for stainless steel sheets. The choice of profile depends on the specific requirements, style preferences, and intended use of the project.

- Q:What is the thickness range available for stainless steel sheets?

- The thickness range available for stainless steel sheets typically varies from 0.4mm to 6mm, depending on the specific requirements and applications.

- Q:Are stainless steel sheets good for exhaust systems?

- Yes, stainless steel sheets are excellent for exhaust systems. Stainless steel is a popular choice for exhaust system materials due to its high resistance to corrosion, heat, and pressure. It can withstand the extreme temperatures and harsh conditions that exhaust systems are exposed to, ensuring durability and longevity. Stainless steel also has excellent acoustic properties, helping to reduce noise levels. Additionally, stainless steel sheets can be easily formed and welded, allowing for the creation of customized exhaust system designs. Overall, stainless steel sheets are a reliable and efficient material for exhaust systems in terms of performance, aesthetics, and overall functionality.

- Q:Can stainless steel sheets be used for medical sterilization equipment?

- Yes, stainless steel sheets can indeed be used for medical sterilization equipment. Stainless steel is a popular material choice in the medical industry due to its excellent resistance to corrosion, high heat resistance, and durability. These features make stainless steel sheets ideal for various medical applications, including the construction of sterilization equipment. Stainless steel sheets can withstand high temperatures and repeated sterilization cycles without warping or degrading, making them suitable for autoclaves and other sterilization devices. Additionally, stainless steel is easy to clean and maintain, which is crucial for preventing the growth of bacteria or other harmful microorganisms. Thus, stainless steel sheets are commonly used in medical settings where sterilization equipment is required.

- Q:What are the different types of textured finishes available for stainless steel sheets?

- There are several different types of textured finishes available for stainless steel sheets, each offering a unique aesthetic appeal and functional benefits. Some of the most common textured finishes include: 1. Brushed Finish: This is the most widely used textured finish for stainless steel sheets. It is achieved through a process of brushing the surface with abrasive materials, creating a distinctive pattern of parallel lines. The brushed finish provides a smooth and elegant appearance while also masking scratches and fingerprints. 2. Embossed Finish: In this type of textured finish, a pattern is stamped onto the stainless steel sheet, creating a raised design. Embossed finishes can range from simple patterns like diamonds or squares to more complex designs. This finish adds depth and visual interest to the metal surface. 3. Bead Blast Finish: This finish is achieved by propelling fine glass beads or ceramic particles onto the stainless steel sheet at high pressure. It creates a uniform matte appearance with a slightly rough texture. Bead blasting is often used for decorative purposes, as it can give stainless steel a unique and contemporary look. 4. Linen Finish: Also known as a cross-hatch finish, the linen finish features a pattern of fine parallel lines that intersect, resembling the texture of linen fabric. This finish is achieved through a process of mechanical rolling or brushing. It provides a textured surface that is both visually appealing and resistant to scratches. 5. Satin Finish: Similar to brushed finish, the satin finish is achieved by brushing the stainless steel sheet with abrasive materials. However, the satin finish has a smoother appearance with a less pronounced pattern of parallel lines. It offers a subtle shine and a refined look, making it a popular choice for architectural and decorative applications. 6. Hammered Finish: This textured finish is created by pounding the stainless steel sheet with a ball-peen hammer or a similar tool. The result is a surface with a unique hammered pattern that adds a rustic and artisanal touch to the metal. Hammered finishes are commonly used in interior design and decorative applications. Overall, the choice of textured finish for stainless steel sheets depends on the desired aesthetic, functionality, and application. Each finish has its own distinct appearance and can enhance the visual appeal of stainless steel while also providing additional benefits such as scratch resistance and fingerprint hiding.

- Q:What are the advantages of using stainless steel sheets in the aerospace industry?

- There are several advantages of using stainless steel sheets in the aerospace industry. Firstly, stainless steel has excellent corrosion resistance properties, which is crucial in environments with high moisture and temperature fluctuations. This helps to maintain the structural integrity of the aircraft and ensures longevity. Additionally, stainless steel sheets offer high strength-to-weight ratio, making them ideal for constructing lightweight yet durable components. They also possess high heat resistance, allowing them to withstand extreme temperatures that may be encountered during flight. Furthermore, stainless steel sheets can be easily formed and fabricated into complex shapes, providing design flexibility. Overall, these advantages make stainless steel sheets a reliable and efficient choice for various aerospace applications.

- Q:Can stainless steel sheets be used in architectural designs?

- Yes, stainless steel sheets can definitely be used in architectural designs. Stainless steel is a versatile material that offers numerous benefits for architectural applications. It is known for its durability, corrosion resistance, and aesthetic appeal, making it a popular choice among architects and designers. Stainless steel sheets can be used in various architectural elements such as cladding, roofing, facades, and decorative features. The material's sleek and modern appearance adds a touch of elegance to any design, whether it's a residential building, commercial structure, or public space. One of the primary advantages of stainless steel sheets is their resistance to corrosion, which makes them suitable for both interior and exterior use. They can withstand harsh weather conditions, UV radiation, and pollutants, ensuring a long-lasting and low-maintenance solution for architectural projects. Additionally, stainless steel sheets are available in different finishes, including brushed, polished, and patterned, allowing architects to create unique and visually appealing designs. The material can be easily formed, welded, and fabricated into various shapes, enabling architects to achieve their desired architectural vision. Stainless steel sheets also offer excellent fire resistance, making them ideal for applications where safety is a priority. They are non-combustible and have a high melting point, providing added protection in case of fire. Furthermore, stainless steel is an environmentally friendly choice. It is 100% recyclable, with a high recycling rate, which reduces the need for new raw materials and helps minimize waste. In conclusion, stainless steel sheets are a versatile and durable material that can be used effectively in architectural designs. Their corrosion resistance, aesthetic appeal, fire resistance, and sustainability make them a popular choice among architects and designers for a wide range of applications.

- Q:How do I prevent stress relaxation on stainless steel sheets?

- To prevent stress relaxation on stainless steel sheets, it is important to avoid subjecting them to excessive heat or prolonged periods of high stress. Additionally, carefully selecting the appropriate grade of stainless steel and implementing proper handling and storage techniques can help minimize stress relaxation.

- Q:Are stainless steel sheets suitable for water treatment applications?

- Yes, stainless steel sheets are suitable for water treatment applications. Stainless steel has excellent corrosion resistance properties, making it ideal for use in water treatment processes. It is highly resistant to rust, staining, and chemical corrosion, ensuring the longevity and durability of the sheets. Additionally, stainless steel is easy to clean and maintain, making it hygienic for water treatment applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel Plate 316Ti with Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords