stainless steel pipes

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

stainless steel pipes

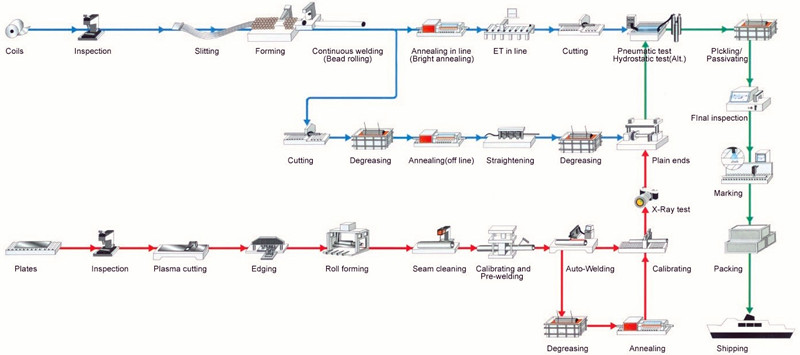

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely used in light industry,heavy industry,daily necessities and the decoration industry.my company long term supply stainless steel porducts including:stainless steel sheet,stainless steel coil and stainless steel tube

Specifications

1.Specification:21.3*3.73mm or others

2.Surface:4k/6k//8k

3.Length:6m or as your requirement

A series of photos

A series of pictures

- Q:How do you prevent noise transmission in stainless steel pipes?

- There exist various effective techniques for preventing noise transmission in stainless steel pipes. 1. Insulation: An effective and commonly used method for preventing noise transmission involves insulating the stainless steel pipes. To absorb and dampen sound waves, insulation materials like mineral wool, fiberglass, or foam can be wrapped around the pipes. This helps in reducing the noise transmitted through the pipes. 2. Vibration isolation: Noise transmission can also be minimized by utilizing vibration isolation techniques. This method entails the installation of flexible connectors or rubber mounts between the pipe and its supports. These isolators absorb vibrations and prevent them from being transmitted as noise through the pipe. 3. Anti-vibration pads: Another approach to prevent noise transmission is the use of anti-vibration pads. These pads are placed beneath the pipe supports to absorb vibrations and prevent their transmission as noise. They act as a barrier between the pipe and its support, significantly reducing noise transmission. 4. Acoustic lagging: The technique of applying a noise-reducing material directly onto the surface of the stainless steel pipes is known as acoustic lagging. This material, often composed of mass-loaded vinyl or rubber, acts as a barrier to block the transmission of sound waves. It effectively reduces noise transmission and can be combined with insulation for improved results. 5. Proper pipe routing: Minimizing noise transmission can be achieved by ensuring proper pipe routing. Pipes should be installed in a manner that reduces contact or proximity to other structures or surfaces that can amplify noise. Additionally, avoiding sharp bends or angles in the pipe can help in reducing noise transmission. It is important to consider that the choice of method may vary based on the specific noise issue and environment. Seeking guidance from a professional acoustic consultant or engineer is recommended to determine the most suitable solution for a particular situation.

- Q:What are the common types of fittings used with stainless steel pipes?

- The common types of fittings used with stainless steel pipes include butt-weld fittings, socket-weld fittings, threaded fittings, and compression fittings. These fittings ensure secure connections between stainless steel pipes, allowing for efficient and reliable fluid or gas flow.

- Q:What are the different types of stainless steel pipe unions?

- There are several different types of stainless steel pipe unions available, each designed for specific applications and requirements. Some of the most common types include: 1. Threaded Union: This type of union is threaded on both ends, allowing for easy installation and disassembly. It is commonly used in low-pressure applications and can withstand moderate temperatures. 2. Socket Weld Union: Socket weld unions have a socket on one end and a male threaded connection on the other. They are designed for high-pressure applications and are commonly used in industrial settings. 3. Butt Weld Union: Butt weld unions have two butt weld connections, one on each end. They are used in applications where a permanent, leak-proof connection is required, such as in pipelines carrying corrosive fluids. 4. Flanged Union: Flanged unions have flanges on both ends, allowing for easy connection to flanged pipes or equipment. They are commonly used in high-pressure and high-temperature applications that require easy installation and disassembly. 5. Compression Union: Compression unions consist of two ferrules and a nut that compresses the ferrules onto the pipe for a tight seal. They are commonly used in plumbing and gas supply systems. 6. Quick Connect Union: Quick connect unions, also known as push-to-connect unions, allow for easy and quick assembly without the need for tools or soldering. They are commonly used in plumbing, irrigation, and air compressor systems. It is important to select the appropriate type of stainless steel pipe union based on the specific requirements of the application, including the pressure, temperature, and compatibility with the fluid being transported. Consulting with a knowledgeable supplier or engineer can help ensure the correct union is chosen for the intended application.

- Q:How do you prevent pitting corrosion in stainless steel pipes?

- To avoid pitting corrosion in stainless steel pipes, there are several steps that can be taken: 1. Select the appropriate grade of stainless steel: Not all stainless steels are equal. Opt for grades that have higher corrosion resistance, such as 316 or 904L, which contain molybdenum and offer better protection against pitting corrosion. 2. Ensure proper alloy composition: Make sure that the stainless steel pipe contains the correct amount of alloying elements like chromium and molybdenum. These elements create a protective layer on the steel's surface, enhancing its resistance to corrosion. 3. Regularly clean and maintain the pipes: Clean the stainless steel pipes on a regular basis to remove any contaminants or deposits that could contribute to pitting corrosion. Avoid using abrasive materials or cleaners that might harm the protective layer. 4. Minimize exposure to aggressive environments: Reduce the stainless steel pipes' exposure to aggressive substances such as chloride ions, acidic solutions, or high temperatures, as these can accelerate pitting corrosion. If exposure is unavoidable, consider applying protective coatings or linings to create a barrier between the steel and the corrosive environment. 5. Employ cathodic protection methods: Implement techniques like sacrificial anode systems or impressed current systems to safeguard the stainless steel pipes. These methods create a potential difference between the stainless steel and a more susceptible metal, diverting corrosion away from the stainless steel. 6. Control water chemistry: If the pipes are used in water applications, monitor and control parameters such as pH, temperature, and chloride levels. Adjusting these factors within acceptable limits can help prevent pitting corrosion. 7. Adhere to proper design and installation practices: Ensure that the stainless steel pipes are designed and installed correctly, considering factors such as avoiding crevices, ensuring proper drainage, and preventing stagnant areas where corrosion can occur. Proper insulation and the use of compatible gaskets or flanges can also prevent pitting corrosion. By following these preventive measures, the risk of pitting corrosion in stainless steel pipes can be significantly reduced, leading to a longer lifespan and maintained structural integrity.

- Q:Are stainless steel pipes magnetic?

- No, stainless steel pipes are generally not magnetic.

- Q:Can stainless steel pipes be used for marine applications?

- Indeed, stainless steel pipes possess the capability to be utilized in marine applications. Renowned for its ability to resist corrosion, stainless steel emerges as an optimal substance to employ within marine surroundings, perpetually exposed to saltwater and elevated humidity levels. By being resistant to both rust and corrosion, stainless steel pipes guarantee their robustness and enduring nature when employed in marine applications. In the marine industry, they find extensive usage for a multitude of purposes, including piping systems, exhaust systems, and structural components. Furthermore, stainless steel pipes exhibit the capacity to endure extreme temperatures and pressures, rendering them suitable for the arduous conditions frequently encountered in marine applications.

- Q:Is galvanized steel pipe stainless steel pipe?

- No, the steel pipe is generally divided into stainless steel pipe, welded steel pipe, spiral steel pipe, low alloy steel pipe and so on.

- Q:How do you prevent discoloration in stainless steel pipes?

- To avoid discoloration in stainless steel pipes, there are several precautions that can be implemented: 1. Implement proper cleaning techniques: It is recommended to regularly cleanse the stainless steel pipes using mild soap or detergent and warm water. The use of harsh chemicals or abrasive cleaners that could potentially harm the surface and result in discoloration should be avoided. 2. Thoroughly rinse the pipes: After cleaning, ensure that the pipes are rinsed thoroughly with clean water to eliminate any residue or cleaning agents that might cause discoloration. 3. Steer clear of corrosive substances: It is advised to keep stainless steel pipes away from direct contact with corrosive substances such as strong acids, alkaline solutions, or chlorides. These substances have the potential to initiate chemical reactions, resulting in discoloration. 4. Apply protective coatings: The application of protective coatings, such as clear lacquer or specialized stainless steel protective sprays, can effectively prevent discoloration by creating a barrier between the metal surface and the environment. 5. Control temperature levels: Excessive heat has the capacity to cause discoloration in stainless steel pipes. Hence, it is crucial to regulate the temperature of the surrounding environment or the fluid passing through the pipes to prevent overheating. 6. Regularly maintain the pipes: Consistent inspections and maintenance should be conducted to promptly identify any indications of discoloration or damage and address them accordingly. This includes checking for leaks, corrosion, or any other factors that may contribute to discoloration. By adhering to these preventive measures, the risk of discoloration in stainless steel pipes can be significantly reduced, enabling them to maintain their aesthetic appeal and functionality for an extended duration.

- Q:What are the different types of fittings used with stainless steel pipes?

- There are several different types of fittings that can be used with stainless steel pipes, depending on the specific application and requirements. Some of the most common types include: 1. Compression fittings: These fittings are designed to create a leak-proof connection by compressing a ferrule onto the pipe. They are easy to install and can be used with both rigid and flexible stainless steel pipes. 2. Threaded fittings: Also known as screwed fittings, these fittings have female threads that allow them to be screwed onto the male threads of the pipe. They are commonly used in low-pressure applications and can be easily installed or removed. 3. Butt weld fittings: These fittings are used to create a permanent, welded connection between two stainless steel pipes. They require the pipes to be beveled to create a V-shaped groove and are typically used in high-pressure or high-temperature applications. 4. Flange fittings: Flanges are used to connect two stainless steel pipes or to connect a pipe to a valve, pump, or other equipment. They provide a strong and leak-proof connection and can be easily bolted or welded onto the pipe. 5. Push-to-connect fittings: These fittings are designed to provide a quick and easy connection without the need for tools or soldering. They use a push-in mechanism to secure the pipe and are commonly used in plumbing and air compression systems. 6. Camlock fittings: Camlock fittings are used to quickly connect or disconnect hoses and pipes. They have a lever or cam mechanism that locks the fitting into place, ensuring a secure connection. They are commonly used in industrial applications where frequent connections and disconnections are required. Overall, the choice of fitting will depend on factors such as the application, pressure requirements, and ease of installation. It is important to select the appropriate fitting to ensure a reliable and durable connection for stainless steel pipes.

- Q:How thick is the 3 stainless steel tube?

- All units of steel default are mm mm. stainless steel 3 thick meaning, that is, the thickness of 3 mm mean

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

stainless steel pipes

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords