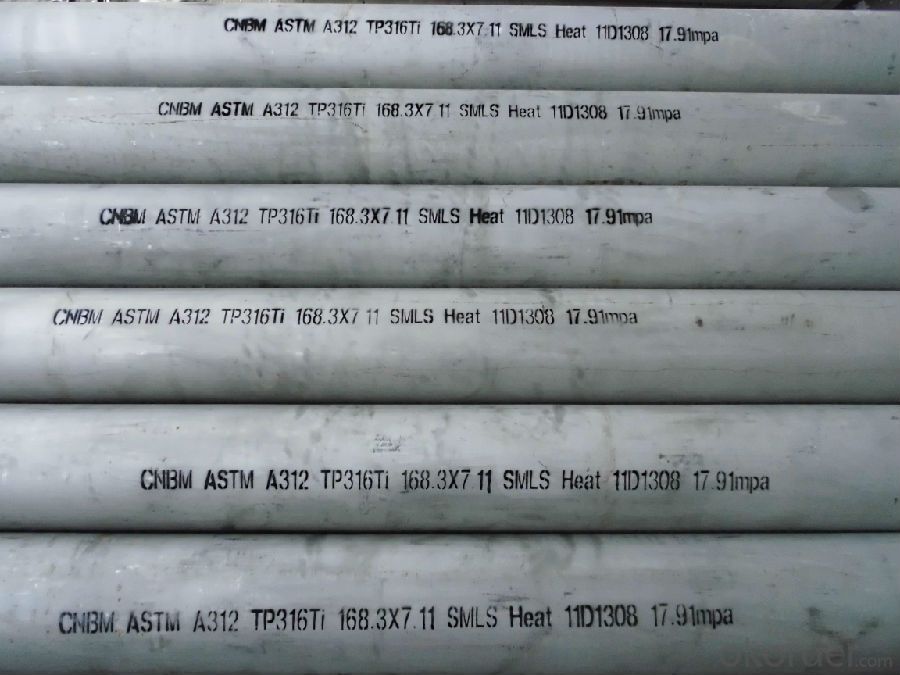

Stainless steel pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

316Ti stainless steel plate is the addition of Ti in SUS316 steel can improve the resistance to intergranular corrosion resistance.

The chemical composition of 316Ti stainless steel:

C (%): less than 0.08

Si (%): less than 1

Mn (%): less than 2

P (%) is less than or equal to: 0.045

S (%) is less than or equal to 0.03

Cr (%): 16 ~ 18

Ni (%): 10 ~ 14

Mo (%): 2 ~ 3

other (%):

5 (C+N) = Ti = 0.70, N = 0.10

The mechanical properties of 316Ti stainless steel:

YS (Mpa) = 205 TS (Mpa) = 520 EL (%) is more than or equal to 40 Hv 200 degrees

- Q:What is the meaning of "DN" and "Phi" in the dimensioning of steel pipe diameter and how to apply the mark?

- DN is a kind of Engineering path, not the actual value, due to the different standards, so the actual corresponding values is not the same; phi is refers to the actual value, the same national standard pipe inside the steel pipe, the actual value is the same, for example, GB/T8163 and GB GB fluid pipe spiral pipe and GBT/T9711.1 GB/T12459 the same nominal diameter corresponding to the actual value is the same as the actual value; and American Standard steel standard ANSI B 16.38 and ANSI B 16.9 standard American Standard fitting the same nominal correspondence is the same. If marked, the nominal diameter should be added DN, and the actual value can be omitted.

- Q:How are steel pipes connected to other plumbing components?

- Steel pipes are commonly connected to other plumbing components through various methods, depending on the specific application and requirements. The most common methods of connecting steel pipes to other plumbing components include threading, welding, and using mechanical fittings. Threading is a process where the ends of the steel pipes are cut and grooves are created on the outer surface to form a threaded connection. This allows the pipes to be screwed into fittings such as elbows, tees, or couplings. Threaded connections are often used in smaller diameter pipes and low-pressure applications. Welding is another commonly used method to connect steel pipes. It involves heating the ends of the pipes and joining them together by melting the metal at the point of contact. This creates a strong and permanent connection. Welded connections are often used in larger diameter pipes and high-pressure applications. Mechanical fittings are another popular option for connecting steel pipes. These fittings are designed to be easily installed without the need for welding or threading. They typically consist of two parts – a compression ring and a nut. The compression ring is placed over the pipe, and the nut is tightened, compressing the ring onto the pipe and creating a secure connection. Mechanical fittings are commonly used in both residential and commercial plumbing systems. In addition to these methods, other connection techniques such as flanges, grooved couplings, and soldering can also be used to connect steel pipes to other plumbing components, depending on the specific needs of the system. Overall, the method used to connect steel pipes to other plumbing components depends on factors such as the size of the pipes, the pressure of the system, the type of fluid being transported, and the specific requirements of the project. It is important to choose the appropriate method and ensure that the connections are properly installed to ensure the integrity and efficiency of the plumbing system.

- Q:How do you calculate the weight of steel pipes?

- To calculate the weight of steel pipes, you can use the formula: weight = volume × density. The volume can be calculated by multiplying the cross-sectional area of the pipe with its length, while the density of steel is typically assumed to be 7850 kilograms per cubic meter.

- Q:How are steel pipes insulated for thermal efficiency?

- Steel pipes are insulated for thermal efficiency by adding a layer of insulation material around them. This insulation helps to reduce heat transfer through the pipes, preventing energy loss and maintaining the desired temperature.

- Q:How do steel pipes compare to other materials, such as PVC or copper?

- Steel pipes are generally considered to be stronger and more durable compared to materials like PVC or copper. While PVC pipes are lightweight and easy to install, they are not as strong as steel and can be more prone to cracking or breaking. Copper pipes, on the other hand, are known for their corrosion resistance and are commonly used for plumbing systems. However, steel pipes have the advantage of being highly resistant to extreme temperatures, pressure, and damage, making them suitable for a wide range of applications, including industrial and commercial use.

- Q:What's the difference between a cracked carbon steel tube and a liquid carbon steel tube?

- Test: cracking carbon steel pipe in addition to eddy current testing, but also to do ultrasonic testing, and liquid carbon steel tubes are generally only eddy current testing.

- Q:What are the common problems or issues faced with steel pipes?

- Common problems or issues faced with steel pipes include corrosion, leakage, cracking, and scaling. Corrosion can occur due to exposure to moisture, chemicals, or environmental factors, leading to reduced structural integrity and potential leaks. Leakage can result from faulty welds, damaged seals, or pipe degradation. Cracking can occur due to excessive stress, temperature fluctuations, or manufacturing defects, compromising the pipe's strength. Scaling or buildup of mineral deposits can also restrict flow and affect performance. Regular inspection, maintenance, and proper coating or lining can help mitigate these issues.

- Q:Can steel pipes be used for underground applications?

- Yes, steel pipes can be used for underground applications. Steel pipes are highly durable and can withstand the pressure and corrosion that may be encountered in underground environments. They are commonly used for various underground applications such as water supply, sewage systems, and underground utility lines.

- Q:What are the different grades of steel used for manufacturing pipes?

- The different grades of steel used for manufacturing pipes vary depending on their intended applications. Some common grades include carbon steel, stainless steel, and alloy steel. Carbon steel is commonly used for general-purpose piping due to its affordability and strength. Stainless steel is preferred for corrosive environments or high-temperature applications due to its resistance to corrosion. Alloy steel, on the other hand, offers improved strength and durability and is often used for specialized applications such as oil and gas pipelines.

- Q:How are steel pipes protected against rusting?

- Steel pipes are protected against rusting through various methods such as galvanization, applying protective coatings, or utilizing corrosion-resistant alloys.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless steel pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords