Stainless Steel Pipe Fittings Butt-Welding Reducing Outlet Tees

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Pipe Fittings Butt-Welding Reducing Outlet Tees

Features standards and products of our butt welding fittings:

Features of Butt-Welding Reducing Outlet Tees:

1. High class materials

Our products only use high class raw materials of carbon/alloy steel pipes made from NKK or MANNESSMANN equipment for ordinary, high pressure, low/high temperature,boiler and other purposes.

2. Uniform wall thickness and perfectly round

This can be achieved by our particular technical knowhow and our quality control program.

3. Accurate dimension

Efficient piping work can be made only with fittings of correct dimensions and shapes. Our fittings are finished to have accurate straight/ plane ends, beveled angle...etc. to applicable standards by means of two or three spindle beveling machines.

Standards of Butt-Welding Reducing Outlet Tees:

Our welding fittings are manufactured in compliance with the following appliance standards:

ASME B16.9 ASTM A234 MSS-SP43 WPHY60 JIS B2311 DIN2605

ASTM A403 MSS-SP75 WPHY65 JIS B2312 DIN2606

ASTM A420 WPHY42 WPHY70 JIS B2313 DIN2616

ASTM A860 WPHY52 DIN2615

Manufacturing method and process of Butt-Welding Reducing Outlet Tees:

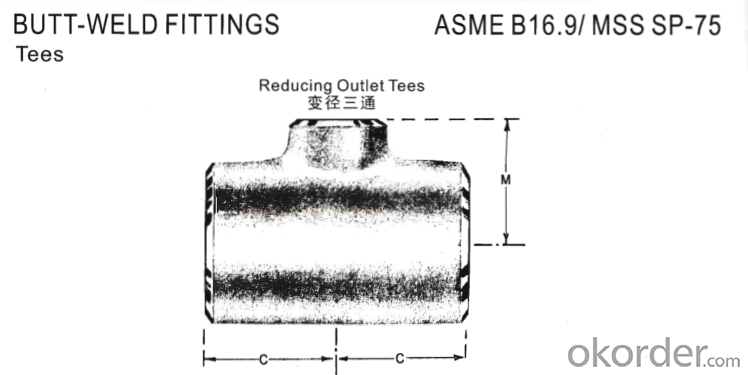

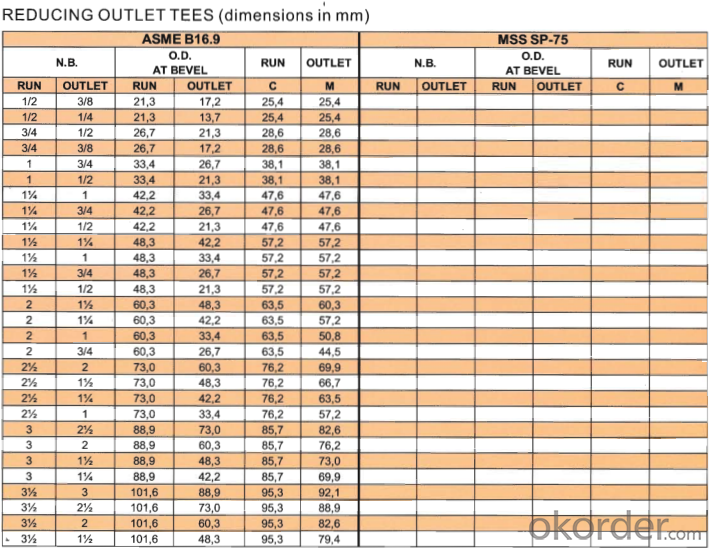

BUTT-WELD FITTINGS ASME B16.9/MSS SP-75

Reducing Outlet Tees:

Packing of Butt-Welding Reducing Outlet Tees:

FAQ of Butt-Welding Reducing Outlet Tees:

1) Q: What’s your main product? Which kinds of products are more competitive in your product range?

A: Our main products are steel flanges, pipe fittings and steel pipes.

Competitive Items: flanges in stainless steel, carbon steel, alloy steel and punching carbon steel

Butt welded pipe fittings in stainless and carbon steel

2) Q: what’s your largest size of flange and fitting? How long is the production cycle?

A: The largest flange we could produce is 80’’ and the largest fitting is 50’’.

In general, we spend 20-25 days in a 20-ton order. If necessary, we could make it shorter.

3) Q: Could you produce according to the drawings?

A: Sure. We could produce according to the provided drawings, which include forged and casted items.

4) Q: What kind of certificates do you have?

A: We have ISO, TUV, API,SGS,BV etc. fittings in stainless and carbon stee

Malleable Iron ,Stainless and carbon steel pipes

- Q:What are the reducing, reducing, reducing, etc in the pipe joint?. How do they tell each other what they call that?. Seek expert advice

- The pipe joint is divided into cylindrical pipe thread and tapered pipe thread, and the change of diameter refers to the different diameters of the two ends of the pipe joint

- Q:I've a dishwashing job at a restaurant, I don't like to wear those annoying rubber gloves that make my hands sweat. Is it really necessary to wear gloves?

- Within the AHU ther are whats called Dampers a device that is designed to stop the spread of fire normally on the air intake side of the ahu as opposed to the extract side of the system. The BMS is where the system programming is and there are many variations of different logics and situations. Simply you will have a smoke detector of some kind in the AHU, and when smoke is detected it sends a signal to the BMS and closes the Damper and / or the Air intake Fan. Probebly from the design of the system smoke detectors are placed in the higher risk places of the system. Hope this helps, I work on these systems all the time. Neil

- Q:the rear dif is locked. Were can I get parts?

- You don't need goggles for all laser light. For something at 20mW though you probably should especially if there is a chance that the beam might be reflected into your eyes (I'm assuming you don't plan on just looking at it directly). Laser Safety (yours would be class 3B):

- Q:How about the water pipe fittings and millimeters?20mm is 425mm is 6Why

- Because, in the past, the workers who used these units were ordinary workers, so that they were easy to operate, and finally became 4 points, 6 points, and so on. In other words, it was also the wisdom of labour

- Q:Okay every alarm in the house has been going off for an hour and its making carbon monoxide ? Whats going on ? I know theres no carbon monoxide cause i'd probably be dead by now

- Try replacing the batteries in all the alarms. You may have one still using older batteries. If that doesn't do it, check the circuit breaker to be sure it hasn't tripped.

- Q:The same is PVC material, one called PVC connector, one to PVC pipe joint, what's the difference?

- Two, plastic pipe type 1, PVC (PVC-U) plastic wire pipe (hard tube), 2 and PE threading pipe (winding hose) 3, plastic bellows (flame retardant bellows, wire harness casing, high density bellows, high temperature protective casing, etc.)Three. Ceramic tube 1, threading porcelain bushing 2, glass fiber woven insulating sleeve

- Q:Hi There,I'm hoping someone may have some feedback on the following.I am trying to install a new door handle with lock for bathroom.Everything appears fine, door locks when it's ajar. However, onceI close the door and lock it, once I try and open it to see if it locks, it just flies open. The knob mechanism seems to be working, locking but I can just open the door without any problem if its in the door unit. why would this happen? Please tell me because I'm about to lose my mind. I've been working on this for over 3 hours. I bless you for your help.

- Buy slip fit couplings and PVC glue. I have never heard of anyone cutting threads for PVC.

- Q:The description says its a kesha song, but I cant find it.

- Copper pipe can be bent but you need to be careful. It will tend to kink if you don't do properly. Try for the widest radius bend as possible. Also copper tends to work harden so if you bend it to often in one spot it can fail.

- Q:i got a blackberry! fuzzy socks lol! ,dkny be delicious perfume, just dance 3 wii game , clothes, boots gift card , boots and a snood! :P and im very thankful for what i got! :)so yeah what did you guys get!?:)kerryxoxoxo

- Maybe just alittle. It would take more faith, to have it stuck to the beanie, on the top of your head. Don't you agree? Hee hee. Peace!

- Q:Why is the water purifier of the PE pipe and quick connector contact after the start of Water Leakage, can be pulled out after turning and then inserted into the PE pipe does not leak, what is the reason ah, who knows?

- Because there is no plug, the fast joint must be inserted in the end, through the internal sealing ring to play a role.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel Pipe Fittings Butt-Welding Reducing Outlet Tees

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords