Stainless Steel Pipe Fittings Butt-Welding End Caps

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Pipe Fittings Butt-Welding End Caps

Features standards and products of our Butt-Welding End Caps:

Features of Butt-Welding End Caps:

1. High class materials

Our products only use high class raw materials of carbon/alloy steel pipes made from NKK or MANNESSMANN equipment for ordinary, high pressure, low/high temperature,boiler and other purposes.

2. Uniform wall thickness and perfectly round

This can be achieved by our particular technical knowhow and our quality control program.

3. Accurate dimension

Efficient piping work can be made only with fittings of correct dimensions and shapes. Our fittings are finished to have accurate straight/ plane ends, beveled angle...etc. to applicable standards by means of two or three spindle beveling machines.

Standards of Butt-Welding End Caps:

Our welding fittings are manufactured in compliance with the following appliance standards:

ASME B16.9 ASTM A234 MSS-SP43 WPHY60 JIS B2311 DIN2605

ASTM A403 MSS-SP75 WPHY65 JIS B2312 DIN2606

ASTM A420 WPHY42 WPHY70 JIS B2313 DIN2616

ASTM A860 WPHY52 DIN2615

Manufacturing method and process of Butt-Welding End Caps:

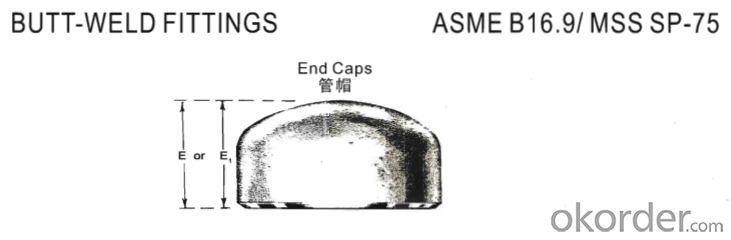

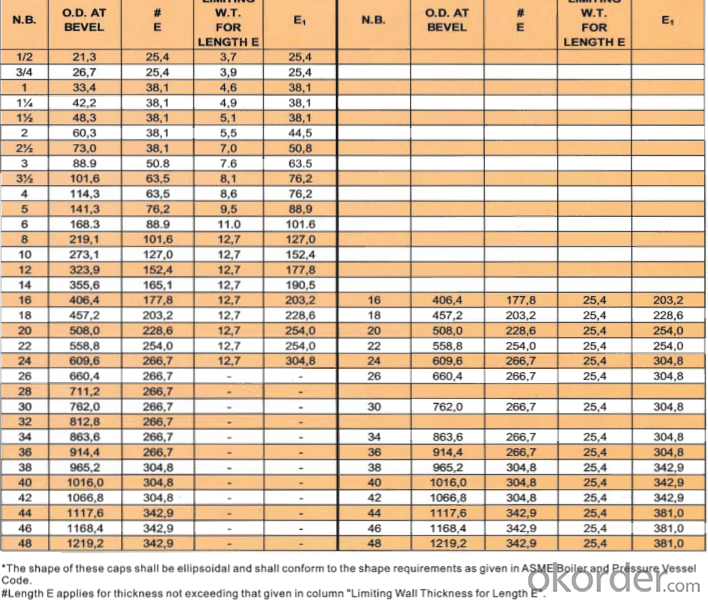

BUTT-WELD FITTINGS ASME B16.9/MSS SP-75

Butt-Welding End Caps:

Packing of Butt-Welding End Caps:

FAQ of Butt-Welding End Caps:

1) Q: What’s your main product? Which kinds of products are more competitive in your product range?

A: Our main products are steel flanges, pipe fittings and steel pipes.

Competitive Items: flanges in stainless steel, carbon steel, alloy steel and punching carbon steel

Butt welded pipe fittings in stainless and carbon steel

2) Q: what’s your largest size of flange and fitting? How long is the production cycle?

A: The largest flange we could produce is 80’’ and the largest fitting is 50’’.

In general, we spend 20-25 days in a 20-ton order. If necessary, we could make it shorter.

3) Q: Could you produce according to the drawings?

A: Sure. We could produce according to the provided drawings, which include forged and casted items.

4) Q: What kind of certificates do you have?

A: We have ISO, TUV, API,SGS,BV etc. fittings in stainless and carbon stee

Malleable Iron ,Stainless and carbon steel pipes

- Q:Capitalism has failed, not because it failed to produce progress or productivity, but because it has done more damage to the ecosystem in the last 100 years than any previous system has done in the past 1 million years. We cannot have free markets as long as free means the freedom to exploit the eArth for ones individual gain. We can not expect a resource based economy to have unlimited growth when resources are finite. I suggest that the prosperity of the last few hundred years is only temporary and not reflective of our past and will not be realistic in the future. We cannot live outside the laws of biology, it will be a big mistake that might jeopardize our species. We must live in in a symbiotic relationship with the planet and that's a fact. Think.

- It's better than nothing, but you might want to invest in a paintball mask or something else because you will still feel the bbs through that.

- Q:This is a heat lamp used in a room where small animals are kept. The sheet metal I'm talking about is located directly above the heating bulb. It reaches quite hot temps. the side is broken off it. i need a high temp glue of some sort to glue it back on. it must be able to not only withstand temps that would normally scorch or melt rubber, but also withstand them without putting out any kind o vapor or fume. there are small animals in this room, so any fumes or vapors could be harmful and must be avoided.

- tricky issue. search with the search engines. that might help!

- Q:Sit by:the fire or a space heater?Drink:hot chocolate or coffee?tea or hot buttered rum?Eat:cookies or cheesecake?turkey or ham?stuffing or mashed potatoes?Wear:hat or earmuffs?scarf or turtleneck?mittens or gloves?Bundle up with:snuggie or blanket/quilt/throw/comforter/etc?socks or slippers?Weather:snow or rain?

- It's the flash. Even when you are wearing make up, the flash of the camera can make your skin look WAAYYYY lighter. So before taking a picture, put on some bronzer. There are some lotions and also some powders that are bronzers. I have white skin and that happens to me, but by wearing bronzer my face doesn't look so pale.

- Q:What type of material will reflect most of the electromagnetic waves coming from a microwave magnetron? What kind of material is the best?

- Maybelline /index?desktop_uri%2F/watch?v8w-B-_7q6NI

- Q:Direct connections as shown in Fig.G1/4.If you do not use the card sleeve, can the thread of the card sleeve be directly connected with the internal thread of the G1/4?

- Some of the threads at the two ends of the sleeve are the same, but some are not the same. Different types of card sleeve connectors will also make a difference. As shown:

- Q:Until what age is a Dalmatian (dog) Stud fertile? We have a pair of dalmatians but the female can't conceive.

- I have joined thousands of metres of pvc pipe never once used a primer, But I do clean the connections first with a clean dry rag! If you can find a product that will actually melt the pvc pipe then that will save you using pvc cement. All you have to do is melt the joining surfaces, not the whole pipe that will secure the joint, when both pieces are pushed together. Never tried super glue, but if you can afford to buy the pvc fittings then whats the worry having to fork out a little extra cash to buy the cement, besides it can always be oncharged to the customer as part of the job! Cheers!!

- Q:I need to know an example of a problem astronauts faced in space preferably 2 examples but one will do. For example, to product the international space station requires a large amount of money. The solution was that by pooling together money, countries are able to achieve more than they could by themselves.

- Depends on the fitting, tractors use a several different types, JIC, ORB, O ring face, standard pipe, just to name a few, and the only one that would require a sealant would be pipe, and the Japanese aint real keen on using pipe, so untill you know what you have your going to need to find out, in a lot of cases you have to relpace the whole hose as the fittings are pressed onto it.

- Q:I have dining room chairs that have a resin like wood. any tips on how to strip and re-stain it? we got this dining room set and realized after we got it home that there was this resin like wood on the back of the chairs and on the columns of the table. We did notice that it is easy to strip off, but we are not sure on how to re-stain it. We did try to re-stain on a spot that is hard to see, but the stain seems to wipe off when it is dried.

- There is a party in my pants now, thank you very much

- Q:Were there fire hoses on the top floors of the Asch Bldg?What was the source of water and water pressure?

- Not me. That's what Congress should have passed instead of the watered down bill the House passed.

- Q:Well, one day, due to lack of excitement in my day, I decided to go on a little computer exploration adventure.I went to Control Panel System Hardware Device Manager Device Manager.However, once I clicked &Device Manager,& I was restricted from accessing &mmc.exe.&So what is this &mmc.exe&/&Device Manager,& and what does it do?

- obviously you don't know what you are doing so call someone who does,,, you can end up burning your house down,,,,and no the horns may not work with just any system,, depends on the voltages used!! and learn english,, there is no such thing as : has went off

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel Pipe Fittings Butt-Welding End Caps

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords