Stainless Steel Pipe Fittings Butt-Welding Concentric Reducers

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Pipe Fittings Butt-Welding Concentric reducers

Features standards and products of our Butt-Welding Concentric reducers:

Features of Butt-Welding Concentric reducers:

1. High class materials

Our products only use high class raw materials of carbon/alloy steel pipes made from NKK or MANNESSMANN equipment for ordinary, high pressure, low/high temperature,boiler and other purposes.

2. Uniform wall thickness and perfectly round

This can be achieved by our particular technical knowhow and our quality control program.

3. Accurate dimension

Efficient piping work can be made only with fittings of correct dimensions and shapes. Our fittings are finished to have accurate straight/ plane ends, beveled angle...etc. to applicable standards by means of two or three spindle beveling machines.

Standards of Butt-Welding Concentric reducers:

Our welding fittings are manufactured in compliance with the following appliance standards:

ASME B16.9 ASTM A234 MSS-SP43 WPHY60 JIS B2311 DIN2605

ASTM A403 MSS-SP75 WPHY65 JIS B2312 DIN2606

ASTM A420 WPHY42 WPHY70 JIS B2313 DIN2616

ASTM A860 WPHY52 DIN2615

Manufacturing method and process of Butt-Welding Concentric reducers:

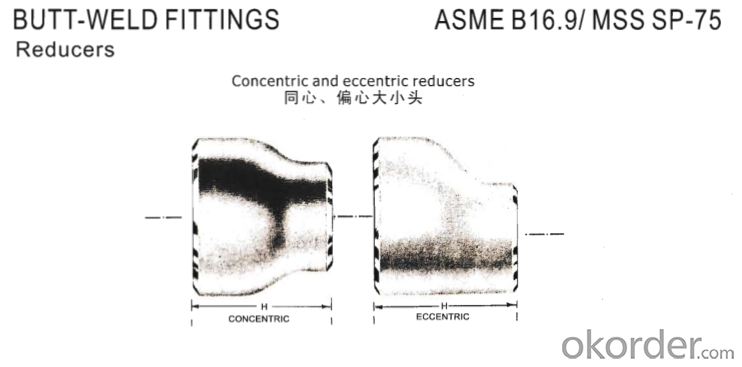

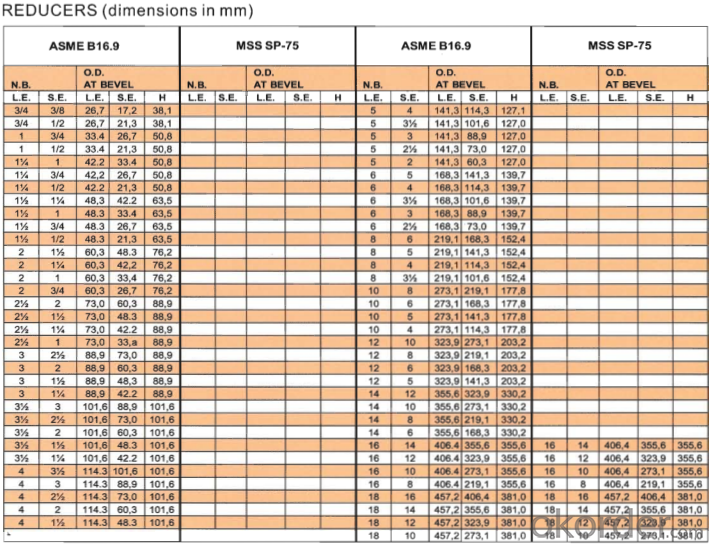

BUTT-WELD FITTINGS ASME B16.9/MSS SP-75

Butt-Welding Concentric reducers:

Packing of Butt-Welding Concentric reducers:

FAQ of Butt-Welding Concentric reducers:

1) Q: What’s your main product? Which kinds of products are more competitive in your product range?

A: Our main products are steel flanges, pipe fittings and steel pipes.

Competitive Items: flanges in stainless steel, carbon steel, alloy steel and punching carbon steel

Butt welded pipe fittings in stainless and carbon steel

2) Q: what’s your largest size of flange and fitting? How long is the production cycle?

A: The largest flange we could produce is 80’’ and the largest fitting is 50’’.

In general, we spend 20-25 days in a 20-ton order. If necessary, we could make it shorter.

3) Q: Could you produce according to the drawings?

A: Sure. We could produce according to the provided drawings, which include forged and casted items.

4) Q: What kind of certificates do you have?

A: We have ISO, TUV, API,SGS,BV etc. fittings in stainless and carbon stee

Malleable Iron ,Stainless and carbon steel pipes

- Q:PVC how to deal with leaking water in the upper opening of three pipe joint of launching pipe?

- To buy a bottle of UPVC dedicated glue, and then go to the production of PVC pipe manufacturers, where they want a little PVC resin powder

- Q:can you be hynotized even if you are wearing contact lens?

- There are distinctive form of fires - electric powered, oil fires and so on and so on and there are categories of extinguishers for all kinds of hearth, in case you utilize the incorrect mixture issues can get lots worse I advise you call your community hearth branch, they are in a position to signify the superb extinguisher for you remember you won't be able to use water for oil fires as a results of fact the ball of flame on oil will glide into yet another section and initiate yet another hearth

- Q:What was the practicle application of the discovery of electricity by Benjamin Franklin after the kite experiment?

- I like Oatey brand Regular clear Advanced cement for PVC. Use a PVC primer first which is usually purple let dry then using the applicator supplied in the can of cement apply a thin even layer to the outside of the pipe and then to the inside of the fitting. Working time is around 30-45 seconds. Insert the pipe into the fitting than give it a half turn. Using excessive amounts of cement is not better. The even layer you have applied will be evenly distributed with the turn of the fitting. GL

- Q:What is a reinforced pipe joint?

- The 200 in the DN80X200 of the pipe joint represents the thickness of the pipe wallPlease accept the answer and support me.

- Q:I hardly ever see this in business establishments but I do see it in homes.

- Sounds like she is trying to make you jealous. Given that the boss is married (and therefore I am assuming straight) you probably have no cause for concern of anything coming of it. However the fact your spouse keeps bringing it up is concerning not to mention disrespectful. I would tell her so.

- Q:I have a young cousin who has gone into law enforcement and needs some puncture proof gloves. Can anyone offer an opinion about which are the safest/best, i.e., name brand, type, etc. Thanks.

- Its not an actual flame its static electricity but if you have seen the glass balls you can touch with your finger and the electricity follows your fingers this is basically what it looks like. There have been reports they call st elmos fire on the ground of balled electricity that floats aroundduring a storm but ive never seen this on the ground,, the only one ive seen is in the air

- Q:Okay, 1st I've though of the most stupidest ideas that pretty much made me worried now. So this is what happend, after reading on how unsafe it was to pierce your lip with a safety pin, I didn't know so I just gone right on ahead and did it, I didn't brush my teeth but I washed my hands, I used rubbing alcohol to clean the safety pin and my lip ring, Okay I used two types of safety pins becuase one was smaller and it didn't fit so I put in bigger one (cleaned with alcohol) in the same hole, it went in and then I put in the lip ring, it was like a loop type lip ring, I put it in and it bled alittle becuase it seemed the loop didn't really fit in but it gone in, I cleaned it afterwards with alchole and proxide. Now I took along time to do it becuase I was nervous. So I checked it was safe.. it wasn't, I took it off asap, I garged proxide and cleaned both sides with alchole, it feels like alittle bubble inside my lip, it looks a bit clean though.. Please don't call me ignorant and help.

- You cannot with the info given. You also need data on the total pipe length, fouling factor, and fittings in line to calculate the flow rate.

- Q:why are lightning rods pointed?

- High voltage engg has to be developed a little more for such accomplishment. Presently , protection devices are installed to protect h.v transmission lines against surge created by stray lightning strike.

- Q:In 1998, I was working at Publix In Fort Pierce, FL. as a front service personnel. I had just finished bringing some groceries to a customers car, and was walking in with the cart in one hand and my umbrella in the other because it was raining. I was at the bottom of the wheelchair ramp going into the building when lightning hit the lightning rod on the building, branched off, and hit me throwing me a good 15 to 20 feet away and knocking me out. When I awoke I was soaking wet. I walked into the store and my manager asked me if I was alright because I was white as a ghost. I had no marks on my body, but ever since I have had problems with intense shaking when I get nervous and my metabolism has never been the same. I also was diagnosed with an anxiety disorder while in boot camp shortly thereafter. Is this the body's normal response to that kind of event and is there anything that I can do to reverse it? If anybody has exrerienced anything similar; I'd appreciate your help.

- images.google .uk/images?hlen

- Q:What does the pipe connector type "10-R1/4" mean?

- (Pipe, joints) hydraulic term is a part of a hydraulic system that connects the pipe or sets the pipe to the hydraulic element. This is a generic term for connections that can be assembled and disassembled in the fluid path.It mainly includes welding type, clamping sleeve type and flaring type.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel Pipe Fittings Butt-Welding Concentric Reducers

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords