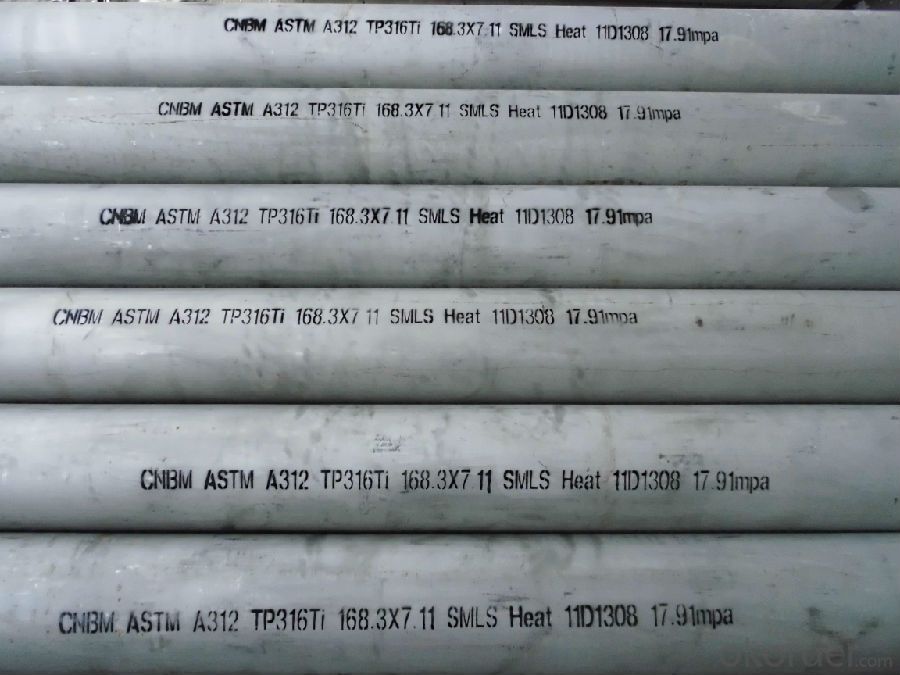

Stainless steel pipe 316Ti 6

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

316Ti stainless steel plate is the addition of Ti in SUS316 steel can improve the resistance to intergranular corrosion resistance.

The chemical composition of 316Ti stainless steel:

C (%): less than 0.08

Si (%): less than 1

Mn (%): less than 2

P (%) is less than or equal to: 0.045

S (%) is less than or equal to 0.03

Cr (%): 16 ~ 18

Ni (%): 10 ~ 14

Mo (%): 2 ~ 3

other (%):

5 (C+N) = Ti = 0.70, N = 0.10

The mechanical properties of 316Ti stainless steel:

YS (Mpa) = 205 TS (Mpa) = 520 EL (%) is more than or equal to 40 Hv 200 degrees

- Q:Are stainless steel pipelines buried in need of corrosion protection?

- The factors of the material itself: stainless steel pipe structure exists because of the equipment, or the existence of cracks of metal or non-metal deposits on the surface, in the sediment and the stainless steel tube surface in the formation of cracks, corrosion, will give priority to produce punctate and ulcer like damage in the crevice, which is crevice corrosion.

- Q:How do you connect stainless steel pipes?

- To connect stainless steel pipes, there are several methods available depending on the specific requirements and applications. The most common methods include welding, threaded connections, compression fittings, and flanges. 1. Welding: Welding is the most reliable and commonly used method for connecting stainless steel pipes. It involves melting the edges of the pipes and fusing them together using a welding electrode. This creates a strong and durable joint. Different welding techniques like TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding can be used depending on the thickness and diameter of the pipes. 2. Threaded Connections: Threaded connections involve screwing together male and female threaded ends of the pipes using pipe thread sealant or Teflon tape. This method is suitable for smaller diameter pipes and low-pressure applications. It provides a secure connection but may not be as strong as welding. 3. Compression Fittings: Compression fittings are used when frequent disassembly is required. These fittings consist of a nut and ferrule that compresses onto the pipe when tightened. They create a tight seal and are commonly used for connecting stainless steel pipes in plumbing or gas distribution systems. 4. Flanges: Flanges are used to connect larger diameter stainless steel pipes or pipes that need to be easily assembled or disassembled. Flanges consist of two mating pieces with a gasket in between. They are bolted together, providing a strong and leak-proof connection. Flanges are commonly used in industrial applications, such as oil and gas, chemical processing, and water treatment plants. It is important to consider the specific requirements, such as pressure, temperature, and the intended application, when choosing the appropriate method to connect stainless steel pipes. Consulting with a professional or following specific guidelines and standards is recommended to ensure a safe and reliable connection.

- Q:What are the limitations of using stainless steel pipes?

- The utilization of stainless steel pipes is associated with several limitations. To begin with, stainless steel pipes are inclined to be pricier in comparison to materials like PVC or copper. This aspect can render them less viable for projects with financial constraints. Moreover, the installation of stainless steel pipes can be more challenging and necessitate the use of specialized tools and equipment. Consequently, this can lead to an increase in both the overall installation time and cost. Another constraint is that stainless steel pipes are unsuitable for the transportation of certain corrosive chemicals or gases. There is a possibility of a chemical reaction occurring with certain substances, resulting in corrosion and potential harm to the pipes. In such scenarios, alternative materials such as plastic or lined pipes may be more suitable. Additionally, stainless steel pipes may possess limitations in terms of their resistance to temperature and pressure. Although they can withstand relatively high temperatures and pressures, extreme conditions may require the utilization of more robust materials. Furthermore, stainless steel pipes exhibit lower thermal conductivity compared to other materials, implying that they are not as efficient in transferring heat. This can be a limitation in certain heating or cooling applications that require rapid heat transfer. Lastly, stainless steel pipes are susceptible to expansion and contraction with changes in temperature. Consequently, the use of expansion joints or other measures may be necessary to accommodate these movements and avoid potential damage. In conclusion, although stainless steel pipes offer numerous advantages such as durability and resistance to corrosion, it is crucial to carefully consider their limitations before selecting them for a specific project.

- Q:Can stainless steel pipes be used for underground drainage systems?

- Indeed, underground drainage systems can utilize stainless steel pipes. Stainless steel proves to be a robust and corrosion-resistant substance capable of enduring the harsh conditions commonly encountered beneath the surface, encompassing moisture, soil chemicals, and fluctuating temperatures. Furthermore, stainless steel pipes exhibit resistance to rust, a prevalent issue faced by alternative pipe materials. Moreover, their extended lifespan and minimal maintenance demands render stainless steel pipes a fitting selection for underground drainage systems.

- Q:What is the difference between 347 and 316 stainless steel pipes?

- The composition and intended use are what sets 347 and 316 stainless steel pipes apart. 347 stainless steel pipes have a higher percentage of niobium, which enhances their stability at high temperatures and resistance to sensitization. This makes them ideal for applications where the pipes will be exposed to elevated temperatures, such as in heat exchangers, furnace parts, and chemical processing equipment. The addition of niobium also improves their resistance to intergranular corrosion. On the other hand, 316 stainless steel pipes consist of molybdenum, which provides increased resistance to corrosion and pitting. This makes them suitable for applications involving exposure to harsh chemicals, saltwater, and other corrosive environments. They are commonly used in industries such as marine, pharmaceutical, and food processing. Both grades have excellent strength and corrosion resistance in terms of mechanical properties. However, 347 stainless steel is generally more expensive than 316 stainless steel due to its higher nickel content. Ultimately, the choice between 347 and 316 stainless steel pipes depends on the specific requirements of the application. If high-temperature stability and resistance to sensitization are crucial, 347 stainless steel pipes would be the preferred option. If the primary concern is corrosion resistance, particularly in harsh environments, 316 stainless steel pipes would be more suitable.

- Q:Can stainless steel pipes be insulated with asbestos?

- No, stainless steel pipes should not be insulated with asbestos. Asbestos is a hazardous material that has been linked to serious health risks, including lung diseases and cancer. It is important to use safe and non-toxic insulation materials when insulating pipes to protect both the environment and human health.

- Q:What is the difference between 2507 and 316 stainless steel pipes?

- The main difference between 2507 and 316 stainless steel pipes is their composition and properties. 2507 stainless steel is a duplex stainless steel alloy that contains higher levels of chromium, molybdenum, and nitrogen compared to 316 stainless steel. This makes 2507 more resistant to corrosion, especially in harsh environments like seawater or chloride-containing solutions. Additionally, 2507 has higher tensile and yield strengths, making it more durable and suitable for applications that require higher strength and resistance to stress cracking. On the other hand, 316 stainless steel is an austenitic stainless steel alloy that offers good corrosion resistance and is widely used in various industries. Overall, the choice between 2507 and 316 stainless steel pipes depends on the specific application requirements and the level of corrosion resistance and strength needed.

- Q:What is the difference between Type 304L and Type 316L stainless steel pipes?

- Type 304L and Type 316L stainless steel pipes are commonly chosen for a variety of uses due to their ability to resist corrosion. However, they differ in their composition and performance in specific settings. The primary distinction lies in their alloy content. Type 304L stainless steel contains 18-20% chromium and 8-12% nickel, whereas Type 316L stainless steel contains 16-18% chromium, 10-14% nickel, and 2-3% molybdenum. The inclusion of molybdenum in Type 316L enhances its corrosion resistance, particularly in environments with high chloride concentrations. As a result, Type 316L is more suitable for applications where the pipes will come into contact with seawater, brine, or other harsh chemicals. Another factor that sets them apart is their mechanical properties. Type 316L stainless steel has slightly higher tensile strength and yield strength compared to Type 304L. It also exhibits better creep and stress rupture properties, making it more appropriate for high-temperature uses. However, for most general purposes, Type 304L is still a good choice, offering excellent durability and longevity. When it comes to cost, Type 316L stainless steel pipes are typically more expensive than Type 304L due to the additional alloying elements. Therefore, the decision between the two will depend on the specific requirements of the application, taking into account factors such as the corrosive environment, temperature, and budget. Overall, while both Type 304L and Type 316L stainless steel pipes provide excellent corrosion resistance, Type 316L offers superior performance in more aggressive environments and higher temperatures. It is advisable to consult with a materials expert or engineer to determine the most suitable stainless steel pipe for a particular application.

- Q:Are stainless steel pipes suitable for food storage facilities?

- Stainless steel pipes are a perfect fit for food storage facilities. The food industry widely embraces stainless steel due to its many advantageous properties. Firstly, stainless steel's resistance to corrosion is crucial in food storage facilities where exposure to moisture and various food products is common. This resistance guarantees that the pipes will not rust or deteriorate over time, thus preventing any potential contamination of the stored food. Furthermore, stainless steel pipes are easy to clean and maintain, making them the ideal choice for food storage facilities that must comply with strict hygiene standards. The smooth and non-porous surface of these pipes prevents the buildup of bacteria, ensuring that the stored food remains safe and uncontaminated. Stainless steel is also a non-reactive material, meaning it does not release any harmful substances into the food. This is particularly important in food storage facilities, as it guarantees the preservation of the integrity and quality of the stored food products. Additionally, stainless steel pipes possess excellent strength and durability, enabling them to withstand the high pressures and temperature fluctuations commonly encountered in food storage facilities. This ensures that the pipes will not fail or break, providing a dependable and long-lasting solution. To conclude, stainless steel pipes are highly suitable for food storage facilities due to their resistance to corrosion, ease of cleaning, non-reactive nature, and strength. They create a safe and hygienic environment for storing food, thereby ensuring the preservation of the integrity and quality of the stored products.

- Q:Are stainless steel pipes suitable for pharmaceutical industries?

- Pharmaceutical industries find stainless steel pipes to be highly suitable. The reason is that stainless steel possesses excellent corrosion resistance and can withstand high temperatures and pressure. These qualities are essential in pharmaceutical applications, where maintaining product purity and preventing contamination are crucial. The non-reactive nature of stainless steel pipes ensures that they do not interact with the pharmaceutical products being transported. This guarantees the integrity and safety of the drugs. Additionally, stainless steel pipes are easy to clean and sanitize, making them ideal for pharmaceutical manufacturing processes that require frequent cleaning. Moreover, stainless steel pipes adhere to the strict regulations and standards set by pharmaceutical authorities. This ensures that the industry's quality and safety requirements are met. They can also be customized to meet specific needs, such as different sizes, shapes, and wall thicknesses, allowing for flexibility in design and installation. In conclusion, stainless steel pipes offer numerous advantages for pharmaceutical industries. These advantages include durability, resistance to corrosion and contamination, ease of cleaning, and compliance with industry standards.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless steel pipe 316Ti 6

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords