Stainless steel pipe #316 durable Construction engineering green energy safety

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 kg

- Supply Capability:

- 300000 kg/month

- Option:

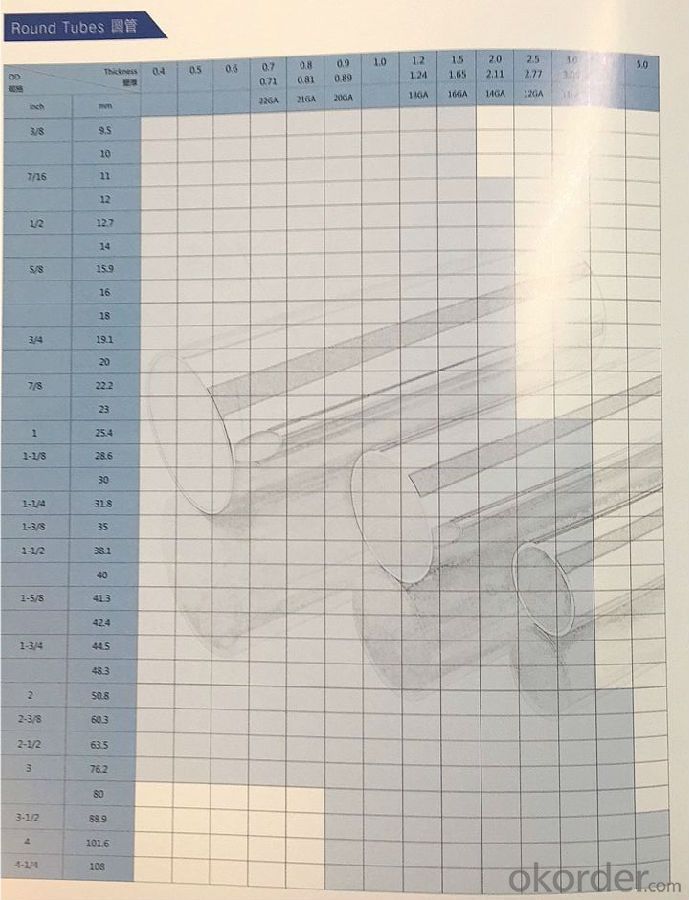

- Stainless steel pipe #316 size

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Our Company has more than 10 years experience in manufacturing and exporting stainless steel pipe and has exported to more than 50 countries and regions. We specializes in manufacturing stainless steel round tube,square tube, retangular tube, oval tube,slot tube and other special shape tube, which are of exquisite workmanship and quality is above industry level. We have several material grade of 201,202,304,304L,316,316L for you choose .

If any inquiry of stainless steel pipe you require, please feel free to contact us to get the quotation.

Strict enforcement of ASTM standard, high welding strength,weld full,non-porosity,free of crack,suitable for tube bending.

Ensure tubes have delicate surface,high brightness and smooth touching,satin finish 180-320 grit,Bright finish 500-600grit(BA),Mirror 800 grit(8K),Which is beyond industry average level and establishes the quality benchmark of (E-PAI).

Automatic plastic bag packaging equipment,PET strap pneumatic packing tool,to dresss up each tube a premium packaging and offer safety protection.

Every tube follows strict quality control during each process,to meet the standard requirements and get 100% customers satisfaction.

Sea worth export bundle paching, dry and clean warehousing ,expert container loading.

Product Description:

Stainless steel pipe

Stainless steel pipe used for construction engineering and house decorative (Extensive )

2. Main features of stainless steel pipe

Reasonable price

High manufacturing accuracy

Good visual effect

- Q:How are steel pipes protected against lightning strikes?

- Steel pipes are protected against lightning strikes by installing lightning rods or grounding systems on top of the structures where the pipes are located. These systems help to divert the electrical discharge from lightning strikes, reducing the risk of damage to the steel pipes.

- Q:Galvanized steel pipe, PPR pipe, PE pipe, U-PVC pipe and HDPE double wall corrugated pipe and what is the difference between the characteristics of

- U-PVC tubes are hard poly vinyl pipes, because they contain chlorine, so they are mainly used in sewer pipes or electrical wiring;HDPE double wall corrugated pipe is a high-density polyethylene pipe, because of its excellent electrical insulation performance, now mainly used for distribution line arrangement.

- Q:What quota should be installed for heating seamless steel pipe?

- Installation quota of seamless steel pipe project, if it is indoor engineering, sets of welded steel pipe, the price adjustment can

- Q:Can steel pipes be used for underground telecommunications networks?

- Indeed, underground telecommunications networks can utilize steel pipes. The strength, durability, and corrosion resistance of steel pipes make them a prevalent choice for underground applications. These pipes offer both protection and support for telecommunication cables, effectively enduring the pressure and load exerted underground. Moreover, applying protective coatings to steel pipes can augment their corrosion resistance and prolong their lifespan. All in all, steel pipes prove to be a dependable option for underground telecommunications networks.

- Q:How are steel pipes used in airport infrastructure?

- Steel pipes are widely used in airport infrastructure for various purposes. They are used for constructing the framework of airport terminals, hangars, and other buildings. Steel pipes are also used for the installation of HVAC systems, electrical wiring, and plumbing in airport facilities. Additionally, steel pipes are used for the construction of runways, taxiways, and aprons, providing a strong and durable foundation for aircraft operations.

- Q:What are the factors to consider when designing a steel pipe system?

- To ensure the functionality, durability, and efficiency of a steel pipe system, several factors must be taken into account during the design process: 1. It is crucial to determine the maximum pressure and temperature the system will be exposed to. This information is essential for selecting the appropriate pipe material, thickness, and jointing method to withstand the system's operating conditions. 2. The selection of the right material for the steel pipes is important. Factors such as corrosion resistance, strength, and cost should be considered. Common materials include carbon steel, stainless steel, and alloy steel. 3. Calculating the adequate pipe size and wall thickness is essential to ensure the required flow rate and pressure drop within the system. The pipe size directly affects the system's efficiency and must be chosen based on the anticipated flow rates and pressure losses. 4. Proper support and anchoring are critical to prevent sagging, movement, and stress on the steel pipe system. The design should take into account the weight of the pipes, the fluid being transported, and any external forces acting on the system. 5. Expansion joints or loops should be incorporated to allow for thermal growth and contraction, preventing damage and distortion caused by temperature variations. 6. Understanding the properties of the fluid being transported, such as corrosiveness, viscosity, and potential for sedimentation or scaling, is important in selecting the appropriate pipe material and protective coatings or linings. 7. Consideration should be given to the accessibility of the system for installation, inspection, and maintenance purposes. The design should include proper access points, valves, and fittings to facilitate easy maintenance and repairs. 8. Environmental factors such as extreme temperatures, humidity, or corrosive substances should be taken into account when selecting the pipe material, protective coatings, and insulation. 9. Compliance with industry standards, codes, and regulations is essential. The design should adhere to safety guidelines and applicable building codes to ensure the integrity and longevity of the pipe system. 10. The overall cost of the steel pipe system, including material, installation, maintenance, and energy consumption, should be considered. Balancing cost-effectiveness with performance requirements is crucial in achieving an efficient and economical design. By considering these factors, engineers and designers can create a steel pipe system that is suitable for its intended purpose, ensuring its longevity, reliability, and safety.

- Q:What are the common welding techniques used for steel pipes?

- The common welding techniques used for steel pipes include Shielded Metal Arc Welding (SMAW or stick welding), Gas Metal Arc Welding (GMAW or MIG welding), Flux-Cored Arc Welding (FCAW), and Gas Tungsten Arc Welding (GTAW or TIG welding).

- Q:How are steel pipes used in the construction of gas distribution networks?

- Steel pipes are commonly used in the construction of gas distribution networks due to their strength, durability, and ability to withstand high pressure. These pipes are used to transport natural gas from the source to homes, businesses, and industries safely and efficiently. They are often buried underground and connected through a network of pipes, allowing for the distribution of gas to various locations. The corrosion-resistant nature of steel ensures the longevity of the pipes, making them a reliable choice for gas distribution infrastructure.

- Q:How to make the magnetic steel, can be like a magnet?

- Magnetization. Winding the insulated wire on the object, passing in the direct current, and taking it down after a period of time.

- Q:Can steel pipes be insulated for thermal efficiency?

- Yes, steel pipes can be insulated for thermal efficiency. Insulating steel pipes helps to reduce heat loss or gain, depending on the application. The insulation material is typically wrapped around the pipes to create a protective barrier. This helps to prevent heat transfer from the pipes to the surrounding environment or vice versa. Insulating steel pipes can significantly improve energy efficiency by reducing the amount of energy required to heat or cool the fluid flowing through the pipes. It is a common practice in various industries such as HVAC, oil and gas, and industrial processes where temperature control is critical. Additionally, insulation also helps to prevent condensation and corrosion on the outer surface of the pipes. Overall, insulating steel pipes is a cost-effective solution to enhance thermal efficiency and reduce energy consumption.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless steel pipe #316 durable Construction engineering green energy safety

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 kg

- Supply Capability:

- 300000 kg/month

- Option:

- Stainless steel pipe #316 size

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords