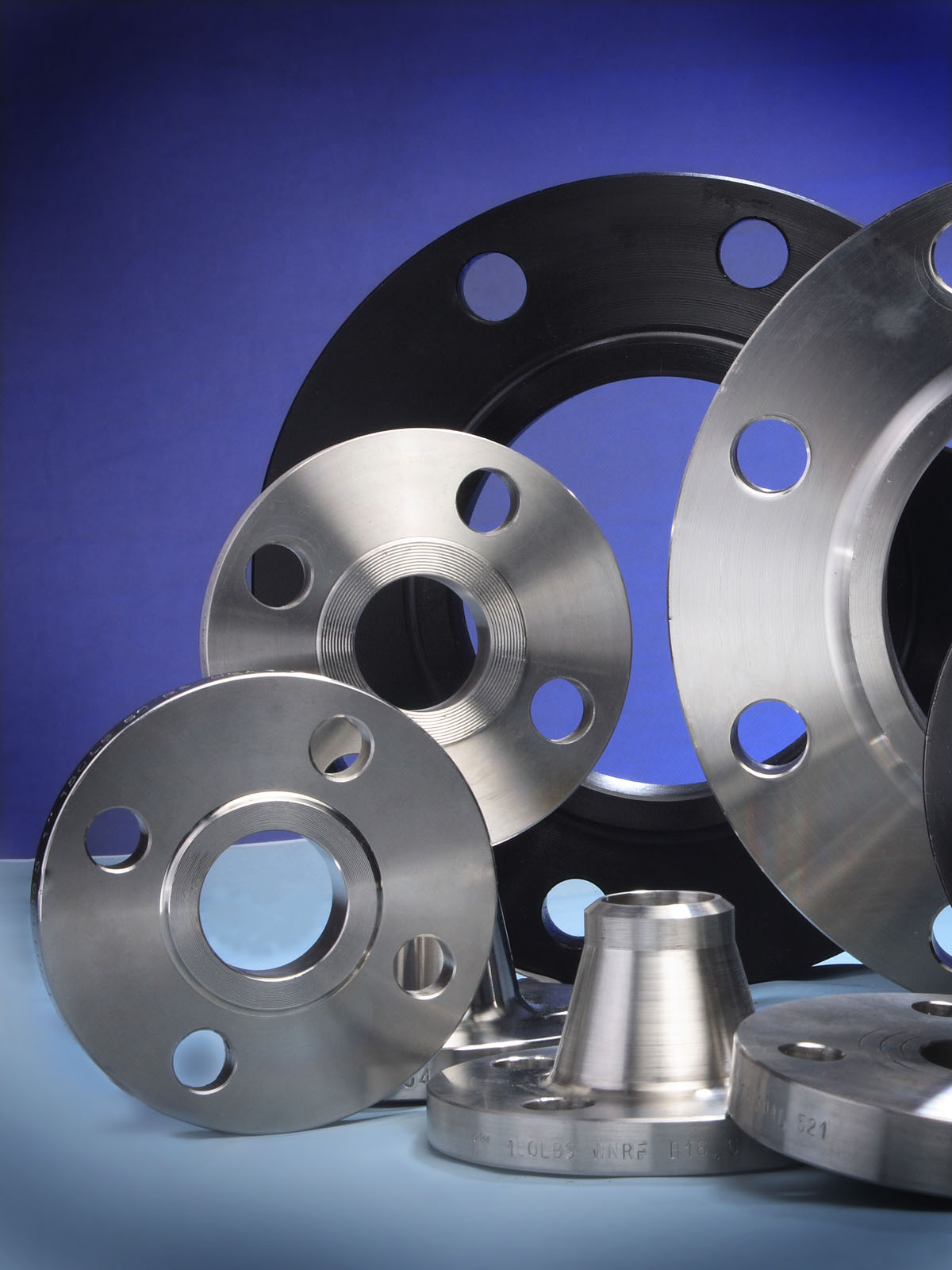

Stainless Steel Fittings TP304

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Pieces pc

- Supply Capability:

- 10000 Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Fittings

Specifications Features:

1) Carbon steel fitting and stainless steel fitting

2) Standard: ASME, ANSI, API, JIS

1. BUTT WELDED FITTING:

2. Production acc. to the standard of GB /ASTM / ASME / DIN / JIS

ASTM B 16.9 /16.11 B 16.28 JIS B 2311/2220 DIN2617/2616/2615/2391

3. Types: Elbows, seamless and welded, LR & SR ,Bend -Equal and reducing Tees,

seamless and welded - Concentric and eccentric Reducers,seamless and welded -Caps

4. Wall thickness: From Sch5 up to Sch160/STD/XS/XXS

5. Material Grades: A403,WP304, WP304L, Wp316, WP316L, A234WPB

6. Dimensions: Seamless: from 1/2' up to 24'

7. size: From 1/2" up to 72"

Outer packing:Seaworthy plywood case

|

Grade |

TP304,TP304L,TP321,TP316L,TP310S etc. |

|

connection |

welding |

|

techniques |

forged |

|

Surface finishing |

180/240/320/400 grit |

- Q:Are stainless steel flats suitable for magnetic applications?

- Yes, stainless steel flats are suitable for magnetic applications. While stainless steel is not inherently magnetic, certain grades of stainless steel can be magnetized through a process known as cold working or by adding specific alloying elements such as nickel or manganese. These magnetizable stainless steels are commonly referred to as austenitic stainless steels. They can exhibit a magnetic response when subjected to a magnetic field, making them suitable for various magnetic applications. However, it is important to note that not all stainless steel flats are magnetic, as there are different grades and types of stainless steel available with varying magnetic properties. Therefore, it is crucial to select the appropriate grade of stainless steel flat that meets the specific magnetic requirements of the application.

- Q:Can stainless steel flats be used in marine environments?

- Yes, stainless steel flats can be used in marine environments. Stainless steel is known for its corrosion resistance, which makes it an ideal material for applications in marine and saltwater environments. The chromium content in stainless steel forms a protective layer on the surface, preventing rust and corrosion. Additionally, stainless steel has good strength and durability, making it suitable for use in marine structures, equipment, and fittings. It is commonly used in the construction of boats, ships, offshore platforms, and other marine components. However, it is important to choose the appropriate grade of stainless steel that is specifically designed for marine environments to ensure optimal performance and longevity.

- Q:Can stainless steel flats be used in water treatment plants?

- Yes, stainless steel flats can be used in water treatment plants. Stainless steel is highly resistant to corrosion and can withstand the harsh conditions and chemicals commonly found in water treatment processes. It is a durable and reliable material choice for various applications in water treatment plants, including piping, tanks, and equipment.

- Q:What are the different types of surface repair methods available for stainless steel flats?

- There are several different types of surface repair methods available for stainless steel flats. One common method is mechanical polishing, which involves using abrasive materials to remove surface imperfections and create a smooth and shiny finish. This method is effective in removing scratches, stains, and other minor damages on the surface of stainless steel flats. Another option is chemical passivation, which is a process that removes free iron and other contaminants from the surface of stainless steel. This method helps to prevent corrosion and improve the overall appearance of the flats. Chemical passivation is particularly useful for removing rust spots or discoloration caused by exposure to harsh environments. In addition, electropolishing is a technique that uses an electric current to remove a thin layer of material from the surface of stainless steel. This method not only helps to remove surface imperfections but also enhances the corrosion resistance of the flats. Electropolishing is commonly used in industries where cleanliness and hygiene are paramount, such as the food and pharmaceutical industries. For more severe damage or deep scratches, grinding and sanding can be employed. Grinding involves using an abrasive wheel or belt to remove a larger amount of material and even out the surface. Sanding, on the other hand, uses sandpaper or sanding pads to gradually smooth out the surface and eliminate scratches. Lastly, if the stainless steel flats have dents or deformations, techniques such as heat straightening or cold working can be used. Heat straightening involves applying controlled heat to the affected area and then using pressure to reshape the metal. Cold working, on the other hand, involves using mechanical force to reshape the flats without the need for heat. In conclusion, the different types of surface repair methods available for stainless steel flats include mechanical polishing, chemical passivation, electropolishing, grinding, sanding, heat straightening, and cold working. The choice of method depends on the extent and nature of the damage, as well as the desired outcome.

- Q:What are the common thickness tolerances for stainless steel flats?

- The common thickness tolerances for stainless steel flats typically range between +/- 0.005 inches to +/- 0.030 inches, depending on the specific grade and size of the flat.

- Q:What are the advantages of using stainless steel flat?

- There are several advantages of using stainless steel flat. Firstly, stainless steel is highly resistant to corrosion, making it suitable for various applications in different environments. Additionally, it has excellent strength and durability, ensuring long-lasting performance. Stainless steel flat also offers aesthetic appeal with its sleek and modern appearance. It is easy to clean and maintain, making it a hygienic choice for industries like food processing and healthcare. Finally, stainless steel is a sustainable material as it can be recycled indefinitely, reducing environmental impact.

- Q:How do you measure the dimensions of stainless steel flats?

- When measuring the dimensions of stainless steel flats, one would typically utilize a measuring tool like a tape measure or caliper. The process entails measuring different aspects of the steel flat, comprising its length, width, and thickness. To determine the length, position one end of the measuring tool at an edge of the flat and extend it towards the opposing edge. It is important to ensure that the tool remains straight and aligned parallel to the flat's edges in order to obtain an accurate measurement. Regarding the width, place the measuring tool perpendicular to the length and position one end at an edge of the flat. Extend the tape measure or caliper towards the opposite edge, making certain that it aligns with the flat's edges. To measure the thickness, resort to a caliper or micrometer. Position the measuring jaws on opposite sides of the flat, ensuring their parallel alignment to each other and perpendicular alignment to the flat's surface. Gently close the jaws to ascertain the thickness measurement. It is imperative to measure multiple points across the flat to account for any disparities. Furthermore, recording the unit of measurement, such as inches or millimeters, is of utmost importance to ensure accuracy and consistency.

- Q:What is the fatigue strength of stainless steel flats?

- The maximum stress level that stainless steel flats can withstand without experiencing failure or fatigue after a certain number of cycles is referred to as fatigue strength. This strength can vary depending on factors such as the grade of stainless steel, surface finish, heat treatment, and the presence of defects or stress concentrations. Stainless steel is renowned for its exceptional fatigue strength, surpassing that of many other materials. Typically, the fatigue strength of stainless steel flats is higher than that of carbon steel or aluminum due to its inherent characteristics, such as high strength, corrosion resistance, and ductility. To express the fatigue strength of stainless steel flats, stress amplitude or stress range is commonly used. Stress amplitude is the difference between the maximum and minimum stress levels experienced during cyclic loading. Fatigue testing is conducted to determine the material's fatigue strength, subjecting it to repeated loading and evaluating its performance based on the number of cycles until failure. The fatigue strength of stainless steel flats can significantly vary depending on the specific grade of stainless steel. Austenitic stainless steels like 304 and 316 generally exhibit favorable fatigue strength properties. Martensitic stainless steels like 410 and 420 are also recognized for their high fatigue strength. It is important to consider factors like surface finish and heat treatment, as they can influence the fatigue strength of stainless steel flats. Smooth surfaces and appropriate heat treatment can enhance the fatigue strength by reducing stress concentrations and improving the material's resistance to cyclic loading. In conclusion, the fatigue strength of stainless steel flats is generally high compared to other materials. However, it can vary depending on the grade of stainless steel, surface finish, heat treatment, and the presence of defects. When determining the fatigue strength for a specific application, it is crucial to take these factors into account.

- Q:What is the thermal shock resistance of stainless steel flats?

- The thermal shock resistance of stainless steel flats is generally high. Stainless steel is known for its ability to withstand sudden temperature changes without significant structural damage. This is due to its low thermal expansion coefficient, which allows it to expand and contract evenly under different temperatures. Stainless steel also has excellent heat conductivity, which helps disperse heat quickly and evenly, reducing the risk of thermal stress. However, it is important to note that the thermal shock resistance can vary depending on the specific grade and composition of stainless steel. Therefore, it is recommended to consult the manufacturer or supplier for more specific information on the thermal shock resistance of a particular stainless steel flat.

- Q:Can stainless steel flats be used in food processing equipment?

- Yes, stainless steel flats can be used in food processing equipment. Stainless steel is widely used in the food processing industry due to its various beneficial properties. It is highly resistant to corrosion, which is essential in an environment where food contact is frequent. Stainless steel also has a smooth and non-porous surface, making it easy to clean and maintain hygiene standards. Additionally, stainless steel is durable and can withstand high temperatures, making it suitable for various food processing applications such as mixing, cutting, and packaging. Overall, stainless steel flats are an excellent choice for food processing equipment due to their durability, corrosion resistance, and hygienic properties.

1. Manufacturer Overview |

|

|---|---|

| Location | Anhui,China |

| Year Established | 2003 |

| Annual Output Value | Above US$16 Million |

| Main Markets | South Korea;Japan; Europe;ASEAN;India |

| Company Certifications | ISO 9001:2000; |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 70% |

| No.of Employees in Trade Department | 160 People |

| Language Spoken: | English;Chinese;Japanese;Korea |

| b)Factory Information | |

| Factory Size: | Above 300,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Stainless Steel Fittings TP304

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Pieces pc

- Supply Capability:

- 10000 Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords