Stainless Steel Coils Grade 304L NO.2B Finish 3mm Thickness Made in China Best Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 18 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Products Description

Product | stainless steel coils/plates/sheets | ||

Discharge Port | Any Port, China | ||

Size | Coils | Cold Rolled: | Thickness0.3-8mm,Width:280-2100mm |

Hot Rolled : | Thickness3-14mm,Width:650-2100mm | ||

Plates | Thickness2-80mm,Width:1500-3000mm | ||

Coil Weight | About 20 Tons | ||

Grade | 201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc. | ||

Technique | Hot Rolled/Cold Rolled | ||

Finish | 2B, BA, 2D, No1, No2, No4,NO.8,SB etc | ||

Edge | Mill Edge / Slitting Edge | ||

Package | In bundles, or as customer's requirement | ||

Place of Origin | Made in China | ||

MOQ | 20 Tons | ||

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy | ||

Delivery Time | With 30-40 days after deposit | ||

Packaging & Delivery

Packaging Detail | Standard export packing or following customer's demand |

Delivery Time | Within 30-40 days after deposit or according to the order quantity |

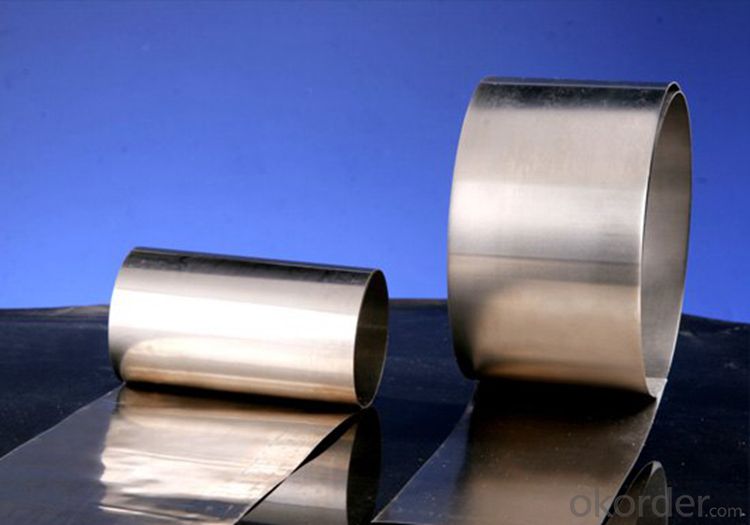

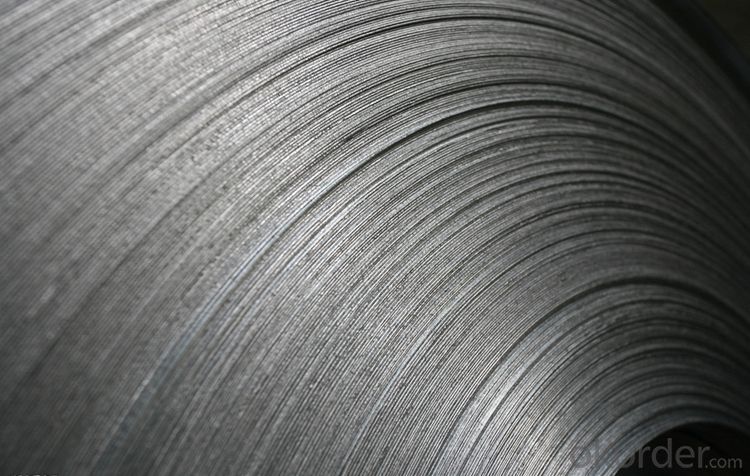

Detail picture of Products:

Application:

Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

FAQ

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q:Can stainless steel sheets be used for solar panel frames?

- Yes, stainless steel sheets can be used for solar panel frames. Stainless steel is a popular choice for solar panel frames due to its high strength, durability, and corrosion resistance properties. It can withstand various weather conditions, including extreme heat, humidity, and exposure to sunlight. Additionally, stainless steel is non-magnetic and non-combustible, making it a safe choice for solar panel installations. Its high strength-to-weight ratio also allows for lighter frame designs, reducing the overall weight of the solar panels and making them easier to install. Overall, stainless steel sheets are a reliable and long-lasting option for constructing solar panel frames.

- Q:Are stainless steel sheets resistant to high temperatures?

- Yes, stainless steel sheets are generally resistant to high temperatures.

- Q:Are stainless steel sheets suitable for elevator wall panels?

- Yes, stainless steel sheets are highly suitable for elevator wall panels. They are durable, corrosion-resistant, easy to clean, and provide a sleek and modern appearance. The material's strength and versatility make it an ideal choice for elevator interiors, ensuring longevity and a visually appealing aesthetic.

- Q:Can stainless steel sheets be used in swimming pool applications?

- Yes, stainless steel sheets can be used in swimming pool applications. Stainless steel is a popular choice for swimming pool construction due to its durability, resistance to corrosion, and aesthetic appeal. Stainless steel sheets can be used for various purposes in swimming pools, such as pool walls, floors, stairs, and water features. They offer excellent strength and are highly resistant to corrosion caused by chlorine and other chemicals present in pool water. Additionally, stainless steel is easy to clean and maintain, making it a practical choice for swimming pool applications.

- Q:What are the different types of edge finishes available for stainless steel sheets?

- Stainless steel sheets can be finished with various edge treatments to achieve different appearances and functionalities. These finishes serve to enhance the sheet's aesthetics, protect against sharp edges and potential corrosion. 1. Mill Finish: The standard edge finish for stainless steel sheets is the raw, untreated edge produced during manufacturing. While it may have a slightly rough or uneven appearance, it is functional and commonly used in industrial applications. 2. Deburred Edges: To eliminate any sharp or jagged edges, the stainless steel sheet can undergo deburring. This involves grinding or sanding down the edges to create a smoother and safer finish. Deburred edges are commonly chosen in safety-sensitive applications like food processing or medical equipment. 3. Rounded Edges: Rounded edges are achieved by utilizing a rounding tool to smooth out the sharp corners of the stainless steel sheet. This finish not only enhances the sheet's aesthetics but also reduces the risk of injury from sharp edges. Rounded edges are often favored for architectural or decorative purposes. 4. Beveled Edges: By cutting or grinding the edge of the stainless steel sheet at a specific angle, typically 45 degrees, beveled edges are created. This chamfered edge adds a sleek and modern appearance to the sheet. Beveled edges are commonly used in applications where aesthetics and design are important, such as furniture or interior design. 5. Polished Edges: Polished edges involve buffing or polishing the edge of the stainless steel sheet to achieve a smooth and mirror-like finish. This edge treatment adds a touch of elegance and sophistication, making it suitable for high-end architectural or decorative applications. To sum up, stainless steel sheets can be finished with mill finish, deburred edges, rounded edges, beveled edges, or polished edges. Each finish offers its own unique benefits and is chosen based on the specific requirements of the application.

- Q:What is the Young's modulus of stainless steel sheets?

- The Young's modulus of stainless steel sheets typically ranges from 190 to 220 gigapascals (GPa).

- Q:What are the different types of stainless steel sheets available?

- When considering stainless steel sheets for your project or application, it is crucial to take into account the specific requirements, as there are several varieties available in the market, each with its own unique properties and applications. Here are some of the most common types: 1. Austenitic Stainless Steel Sheets: Widely used and highly popular, this type of stainless steel offers exceptional corrosion resistance, high strength, and good formability. It finds extensive usage in kitchen equipment, food processing plants, and pharmaceutical industries. 2. Ferritic Stainless Steel Sheets: Distinguished by a higher chromium content and lower carbon content in comparison to austenitic stainless steel, ferritic sheets are renowned for their outstanding stress corrosion cracking resistance. They are commonly utilized in automotive applications, architectural structures, and appliances. 3. Martensitic Stainless Steel Sheets: Boasting a higher carbon content than other types, martensitic sheets provide exceptional strength and hardness. They are frequently employed in applications requiring wear resistance, such as cutlery, surgical instruments, and turbine blades. 4. Duplex Stainless Steel Sheets: These sheets possess a mixed microstructure of austenite and ferrite, offering a combination of high strength and excellent corrosion resistance. They often find application in chemical processing plants, oil and gas industries, and marine environments. 5. Precipitation Hardening Stainless Steel Sheets: Heat-treatable and known for their high strength and corrosion resistance, precipitation hardening sheets are commonly found in aerospace applications, defense equipment, and high-performance industries. Considering the unique properties and advantages of each type, it is crucial to carefully evaluate the specific requirements of your project or application when selecting the appropriate stainless steel sheet.

- Q:Stainless steel plate how to distinguish between good and bad, there are several thick?

- The entire stainless steel material, its origin is generally mills order or to import and processing of goods due to overstocking of society. The sources of stainless steel are different, and the methods of identification are different.

- Q:What are the factors to consider when selecting the right grade of stainless steel sheet?

- When selecting the right grade of stainless steel sheet, there are several factors that should be considered. First and foremost, it is important to consider the intended application of the stainless steel sheet. Different grades of stainless steel have varying levels of corrosion resistance, strength, and temperature resistance. Therefore, understanding the specific requirements of the application, such as exposure to corrosive environments or high temperatures, is crucial in selecting the appropriate grade. The next factor to consider is the desired appearance and finish of the stainless steel sheet. Some grades of stainless steel are more suitable for achieving a highly polished or mirror-like finish, while others are better suited for a brushed or matte appearance. Additionally, certain grades may be more resistant to scratching or showing fingerprints, which can be important in applications where aesthetics are a priority. Cost is another important factor to consider when selecting the right grade of stainless steel sheet. Different grades of stainless steel can vary significantly in price, depending on factors such as the alloying elements used, manufacturing process, and availability. It is important to balance the desired properties and performance of the stainless steel sheet with the available budget. The ease of fabrication and welding is also a critical factor to consider. Some grades of stainless steel are more easily machinable and formable than others, making them better suited for certain fabrication processes. Similarly, certain grades have better weldability, which can be important in applications where welding is required. Lastly, it is important to consider the availability and sourcing of the selected grade. Some grades of stainless steel may be more readily available in certain regions or from specific suppliers. It is important to ensure that the selected grade can be easily sourced to avoid delays or increased costs in the supply chain. In conclusion, when selecting the right grade of stainless steel sheet, factors such as the intended application, desired appearance, cost, ease of fabrication and welding, and availability should all be carefully considered. By evaluating these factors, one can make an informed decision and select the most appropriate grade of stainless steel sheet for their specific requirements.

- Q:Are stainless steel sheets good for industrial exhaust systems?

- Yes, stainless steel sheets are an excellent choice for industrial exhaust systems. They offer high resistance to corrosion, extreme temperatures, and chemicals typically found in exhaust gases. Additionally, stainless steel sheets have excellent durability and strength, making them suitable for heavy-duty industrial applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel Coils Grade 304L NO.2B Finish 3mm Thickness Made in China Best Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 18 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords