Stainless Steel Coil /Sheet in Wuxi, China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

stainless steel coil

1. Standard: ASTM A240, JIS G4304, G4305, GB/T 4237, GB/T 8165, BS 1449, DIN17460, DIN 17441

2. Grade: 200series&300series&400series

3. Thickness: 0.23mm-0.8mm

4. Diameter: 115-560mm

5. Length: according buyer require

6. Surface finish: 2B, BA, 8K, 6K, Mirror Finished, No1, No2, No4, Hair Line with PVC

7. Manufacture technology: cold drawn/cold rolled/hot rolled

1) Product feature:

| 1. Commordity: | stainless steel coil, stainless steel sheet |

| 2. Thickness: | 0.3mm~5.0mm |

| 3. Width: | 6mm~500mm, 1219mm, 1500mm |

| 4. Surface: | Shiny surface, 2B, 2R, BA |

| 5. Standard: | ASTM A240 |

| 6 Finishing: | Cold rolled + annealed |

| 7. Materials: | 301, 304, 304L, 316, 316L, 316Ti, 317L, 321, 347, S31803 (F51), S32205 (F60), 32750 (F53), S32760 (F55), 17-7PH ( 631), 904L |

| 8. Material origin: | TISCO, POSCO, LISCO, ZPSS, Bao steel, Krupp etc |

| 9. Application: | Flexible metal hose, air duct, Gasket, tower packing, power cable & oil well, washer, packing, heat exchanger, conveyor belting |

| 10. Coil ID: | 300MM, 400mm, 500mm as per customers’ request |

| 11. Coil weight: | as per client’s requirement. |

| 12. Delivery time | Be ready for shipment within 15~20 days upon receipt PO |

| 12. Package: | Plywood boxes. ( See pictures below ) |

| 13. Certificate: | ISO, BV, SGS, Mill test certificate |

| 14. Product quality: | Good & prime |

| 15. More information: | Contact Vivian (MP/WhatsApp/Viber: 0086-13921352562) skype: vivian.316L |

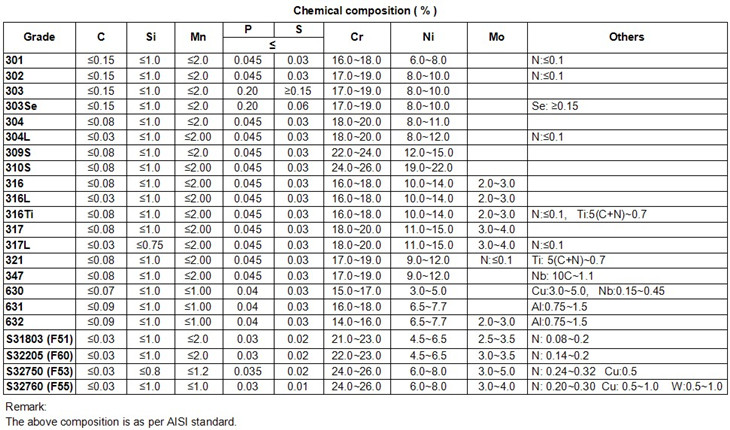

2) Chemical composition:

3) Product picture display:

- Q:What are the weight and length options for stainless steel strips?

- The weight and length options for stainless steel strips can vary depending on the specific requirements and manufacturer. Typically, stainless steel strips come in various weight options ranging from lighter gauges (such as 0.001 inches or less) to heavier gauges (such as 0.125 inches or more). Similarly, length options can vary from shorter coils or rolls to longer lengths, commonly ranging from a few feet to several hundred feet. It is important to consult with the manufacturer or supplier to determine the specific weight and length options available for stainless steel strips.

- Q:Are stainless steel strips resistant to corrosion?

- Stainless steel strips possess corrosion resistance due to their composition. They consist of iron, chromium, and other elements that create a protective layer on the metal's surface. This layer, referred to as a passive film, acts as a barrier between the metal and oxygen and moisture, which are the primary factors behind corrosion. The formation of this protective film is attributed to the chromium content in stainless steel. The higher the chromium content, the greater the corrosion resistance. Consequently, stainless steel strips are renowned for their exceptional ability to withstand corrosion, rendering them suitable for numerous applications across diverse industries.

- Q:Can stainless steel strips be used in water treatment applications?

- Certainly! Stainless steel strips have the ability to be utilized in water treatment applications. Due to its remarkable resistance to corrosion, stainless steel can endure being exposed to water and the assortment of chemicals commonly employed in water treatment procedures. Furthermore, it demonstrates durability and possesses a lengthy lifespan, rendering it appropriate for implementation in demanding environments. Various water treatment applications, including filtration systems, pumps, valves, and tanks, can employ stainless steel strips. In addition, stainless steel is considered hygienic as it discourages the growth of bacteria, thus proving its suitability for utilization in water treatment facilities where preserving water quality is of utmost importance.

- Q:What are the common thickness tolerances for stainless steel strips?

- The common thickness tolerances for stainless steel strips can vary depending on the specific industry standards and requirements. However, in general, the common thickness tolerances for stainless steel strips range from ±0.0015 inches to ±0.005 inches. These tolerances ensure that the stainless steel strips meet the desired thickness specifications and maintain consistent quality throughout the manufacturing process. It is important to note that these tolerances may vary depending on the specific grade of stainless steel and the intended application of the strips. Manufacturers and customers often communicate and agree upon the specific tolerances needed to meet their unique requirements.

- Q:What are the common dimensions of stainless steel strips?

- The dimensions of stainless steel strips can differ based on the particular application and industry in question. Nevertheless, there are several standard measurements that are commonly accessible. Stainless steel strips typically come in widths that range from 0.5 inches to 24 inches (1.27 cm to 60.96 cm) and thicknesses that range from 0.005 inches to 0.25 inches (0.0127 cm to 0.635 cm). Lengths may differ based on the supplier and the customer's requirements, but standard lengths are often approximately 12 feet (3.66 meters) or 20 feet (6.1 meters). It is worth mentioning that these measurements are not exhaustive and may fluctuate depending on the specific demands of the project or industry.

- Q:What are the different packaging options for stainless steel strips?

- Stainless steel strips have various packaging options available to cater to the specific requirements and preferences of customers: 1. Coils: Coils are tightly wound stainless steel strips that are secured with straps or plastic wrap. They offer easy handling, transportation, and storage, making them efficient for large quantities. 2. Wooden Crates: For enhanced protection and durability, stainless steel strips can be packed neatly in wooden crates. Straps or foam inserts are used to secure the strips, preventing damage during shipping or storage. Wooden crates are commonly used for heavy-duty applications or long-term storage. 3. Pallets: Stainless steel strips can also be packaged on pallets, where they are stacked and secured with bands or shrink wrap. This option allows for convenient handling using forklifts and ensures stability during transportation. Pallets are suitable for smaller quantities of strips. 4. Bundles: Bundling stainless steel strips together using plastic or steel bands keeps them organized and secure, preventing tangling or damage. Bundles are ideal for smaller quantities, offering easy handling and storage. 5. Custom Packaging: Custom options for packaging stainless steel strips can be tailored to specific customer needs. This may involve adding protective covers, foam inserts, or custom labeling for easy identification. Custom packaging ensures adequate protection and readiness for use upon delivery. In conclusion, the packaging options for stainless steel strips vary depending on factors such as quantity, transportation requirements, and desired level of protection. Manufacturers and suppliers collaborate closely with customers to determine the most suitable packaging option, ensuring the safe and efficient delivery of stainless steel strips.

- Q:What are the common widths of stainless steel strips?

- Depending on the specific application and industry, the widths of stainless steel strips can differ. In general, stainless steel strips are available in widths ranging from 0.5 inches (12.7 mm) to 36 inches (914.4 mm). These widths are commonly utilized in industries like automotive, construction, manufacturing, and aerospace. It is important to mention that custom widths can also be manufactured to meet specific project requirements.

- Q:Can stainless steel strips be used in renewable energy applications?

- Yes, stainless steel strips can be used in renewable energy applications. Stainless steel is a durable and corrosion-resistant material that can withstand various environmental conditions, making it suitable for use in renewable energy technologies such as solar panels, wind turbines, and geothermal systems. It is commonly used in the construction of frames, supports, and structural components in these applications due to its strength and resistance to rusting or degradation over time.

- Q:What are the factors that affect the corrosion resistance of stainless steel strips?

- The corrosion resistance of stainless steel strips can be affected by several factors. These factors include the composition of the alloy, the formation of a passive film, the surface finish, environmental conditions, stress corrosion cracking, and the manufacturing processes. 1. The corrosion resistance of stainless steel depends on its alloy composition. Stainless steel is typically made up of iron, chromium, and other elements like nickel, molybdenum, and nitrogen. The higher the chromium content, the better the corrosion resistance. Other alloying elements also contribute to the overall corrosion resistance. 2. When stainless steel is exposed to oxygen, it forms a protective film on its surface. The stability and thickness of this film depend on factors like alloy composition, surface condition, and environmental conditions. Any damage to the film can compromise the corrosion resistance. 3. The surface finish of stainless steel strips can greatly impact their corrosion resistance. Smooth and polished surfaces are less susceptible to corrosion compared to rough surfaces, as they provide fewer areas for corrosive agents to attack. 4. The environment in which stainless steel strips are used can significantly affect their corrosion resistance. Factors like temperature, humidity, pH level, and the presence of corrosive agents like chloride ions or sulfur compounds can accelerate corrosion. Stainless steel strips used in marine, industrial, or highly corrosive environments may require higher corrosion resistance. 5. Stress corrosion cracking is a type of corrosion that stainless steel can be susceptible to, especially in environments containing chlorides or sulfides. This type of corrosion occurs due to the combined effects of tensile stress and corrosive agents, leading to the formation of cracks. The susceptibility to stress corrosion cracking can vary depending on the alloy composition and environmental conditions. 6. The manufacturing processes and heat treatment involved in producing stainless steel strips can also affect their corrosion resistance. Improper heat treatment or inadequate manufacturing processes can result in a decrease in corrosion resistance. In conclusion, the corrosion resistance of stainless steel strips is influenced by various factors, including alloy composition, passive film formation, surface finish, environmental conditions, stress corrosion cracking susceptibility, and manufacturing processes. It is important to consider these factors when choosing the appropriate grade of stainless steel for specific applications to ensure optimal corrosion resistance.

- Q:How is stainless steel strip manufactured?

- The process of manufacturing stainless steel strip includes shaping and cutting stainless steel sheets. To start, high-quality stainless steel alloy is selected, typically containing chromium and nickel, which provides durability and resistance to corrosion. The manufacturing process begins by feeding the stainless steel sheets into a rolling mill, where they pass through multiple sets of rollers. These rollers gradually reduce the thickness of the sheets, resulting in a thinner and longer strip. This rolling process is repeated multiple times to achieve the desired thickness and dimensions. After the rolling process, the stainless steel strip undergoes annealing to remove internal stresses and improve its ductility. Annealing involves heating the strip to a specific temperature and then slowly cooling it. This process enhances the mechanical properties of the strip and makes it easier to work with in subsequent manufacturing steps. Once annealed, the strip may undergo additional processes depending on the desired end-use. These processes may include pickling or passivation to remove impurities or oxides and improve the surface finish. The strip may also be coated or polished to enhance its appearance or protect it from corrosion. Finally, the strip is cut into the desired lengths using shearing or slitting machines. Shearing involves cutting the strip in a straight line to create individual pieces of the desired width. Slitting, on the other hand, involves cutting the strip into narrower widths, commonly used for applications such as flexible metal hoses or electrical components. Overall, precise control of rolling, annealing, and cutting processes is essential in the manufacturing of stainless steel strip to ensure the production of high-quality strips that meet required specifications and standards. These stainless steel strips are widely used in various industries such as automotive, aerospace, construction, and manufacturing due to their excellent corrosion resistance, strength, and versatility.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel Coil /Sheet in Wuxi, China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords