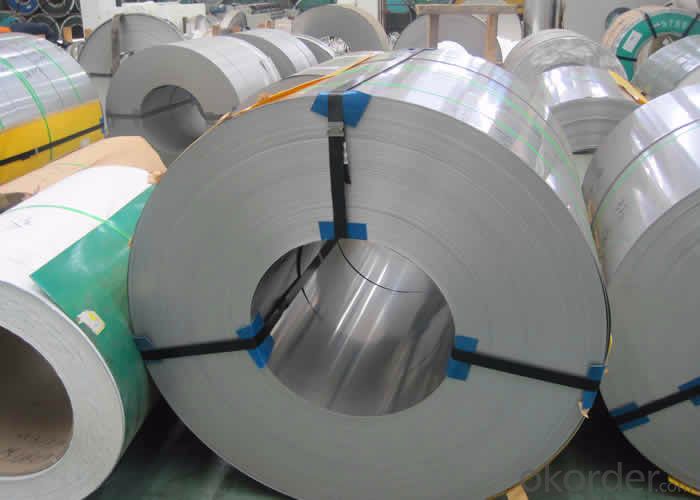

Stainless Steel Coil 201 Hot Rolled Narrow Coil J3

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Rolled Stainless Steel Coil

201 Narrow/Wide Strip No.1 Finish

Packaging Detail: For customer's requirement

Delivery Detail: 10-30days

201 Hot Rolled Stainless Steel Coil Specifications

THK:2.3/2.5/3.0/4.0mm

Width:485/510/550/610/1010/1240mm

Face:No.1

201 Hot rolled stainless steel Coil Application

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely

used in light industry,heavy industry,daily necessities and the decoration industry.

201 Hot Stainless Steel Coil Chemical Composition(WT%)

(C):≤0.15, (Si):≤0.75, (Mn):5.5~7.50, (Cr):16.0~18.0, (N):≤0.25, (Ni):3.50~5.50, (P):≤0.060, (S):≤0.030

201 Hot Rolled Stainless Steel Coil

Strength Of Extension:100,000 To 180,000 Psi;

Yield Strength:50,000 To 150,000 Psi

Elongation :55 To 60%;

Modulus Of Elasticity:29,000,000 Psi;

Density :.280lbs/Cubic Inch(7.93g/Cm3)

- Q:How do stainless steel strips perform in abrasive environments?

- Stainless steel strips perform exceptionally well in abrasive environments due to their high resistance to corrosion, rust, and wear. The inherent properties of stainless steel, such as its chromium content, form a protective oxide layer that shields the material from abrasive elements. This enables stainless steel strips to withstand harsh conditions, maintain their strength, and retain their aesthetic appeal even in abrasive environments.

- Q:Can stainless steel strips be used in marine environments?

- Yes, stainless steel strips can be used in marine environments. Stainless steel is highly resistant to corrosion, making it an ideal material for applications in marine environments where there is constant exposure to saltwater, moisture, and other harsh conditions. The chromium content in stainless steel forms a protective layer on the surface, known as a passive film, which helps to prevent corrosion and rusting. Additionally, stainless steel has excellent strength and durability, making it suitable for marine applications such as boat fittings, marine hardware, and structural components. It is important to select the appropriate grade of stainless steel for marine applications, with 316 and 316L being the most common grades used due to their higher resistance to corrosion. Regular maintenance and cleaning are also recommended to ensure the longevity and performance of stainless steel strips in marine environments.

- Q:Can stainless steel strips be used in pharmaceutical applications?

- Yes, stainless steel strips can be used in pharmaceutical applications. Stainless steel is highly corrosion resistant and has excellent mechanical properties, making it a suitable material for various pharmaceutical processes. It is commonly used in the manufacturing of pharmaceutical equipment, such as storage tanks, mixing vessels, and piping systems. Stainless steel strips are often used for fabricating components that require high strength, durability, and resistance to chemicals and cleaning agents. Additionally, stainless steel is non-reactive and does not leach any harmful substances, ensuring the integrity and purity of pharmaceutical products.

- Q:Can stainless steel strips be used in aerospace applications?

- Yes, stainless steel strips can be used in aerospace applications. Stainless steel is known for its high strength, corrosion resistance, and durability, making it an ideal material for various aerospace components such as aircraft frames, engine parts, and structural elements.

- Q:Can stainless steel strips be used in high-temperature environments?

- Indeed, one can utilize stainless steel strips in environments with elevated temperatures. Stainless steel exhibits remarkable heat resistance properties, rendering it ideal for scenarios that entail exposure to extreme temperatures. The extent of its heat resistance relies on the particular grade of stainless steel employed and the temperature range involved. Nonetheless, the majority of stainless steel grades can endure temperatures of up to 1000°C (1832°F) without compromising their mechanical attributes. Moreover, stainless steel's capacity to thwart oxidation and corrosion further enhances its aptness for high-temperature settings.

- Q:Is there any magnetism in stainless steel?

- Iron and steel are different in terms of carbon content. An iron carbon alloy with a carbon content of less than 2% is a steel, and a carbon content of more than 2% is called iron. Steel is widely used because of its toughness, elasticity and rigidity. Life is exposed to steel, but people call different. For stainless steel, whether or not the magnet is sucked on or not, as long as the quality standards are met, it is stainless steel. Therefore, from the perspective of metallurgy said, no rust said. The main element of stainless steel corrosion resistance is chromium. If the content of chromium is above 10.5%, the steel will not rust. When smelting, the alloy elements added are different, so there is a difference between the magnet and the suction. Stainless steel is usually divided according to the structure of the organization, can be divided into austenite, ferrite, martensite and other major categories.

- Q:What are the common uses of stainless steel strips in the construction industry?

- Stainless steel strips are widely used in the construction industry for various purposes. One common use of stainless steel strips is in the fabrication of structural components such as beams, columns, and braces. These strips provide excellent strength and durability, making them ideal for supporting heavy loads and ensuring the structural integrity of buildings. Another common use of stainless steel strips in construction is for cladding and decorative purposes. Stainless steel strips can be used to cover exterior walls, roofs, and facades, providing a sleek and modern aesthetic to the building. The corrosion-resistant properties of stainless steel make it an excellent choice for such applications, as it can withstand harsh weather conditions and maintain its appearance over time. Stainless steel strips are also used in the construction of handrails, balustrades, and guardrails. These components are essential for safety purposes, and stainless steel's high strength and corrosion resistance make it a reliable material for such applications. Additionally, stainless steel strips can be easily shaped and formed, allowing for the creation of intricate and visually appealing designs. Furthermore, stainless steel strips find application in the construction of infrastructure projects such as bridges and tunnels. These structures require materials that can withstand heavy loads, extreme temperatures, and exposure to moisture. Stainless steel strips possess these qualities, making them a popular choice for the construction of durable and long-lasting infrastructure. In summary, stainless steel strips have numerous common uses in the construction industry. They are used for structural components, cladding, decorative purposes, handrails, balustrades, guardrails, and infrastructure projects. The versatility, strength, and corrosion resistance of stainless steel make it an ideal material for these applications, ensuring the longevity and quality of construction projects.

- Q:Can stainless steel strips be used in the oil refinery equipment?

- Indeed, it is possible to utilize stainless steel strips in the equipment of oil refineries. Stainless steel, being an incredibly durable and resistant material against corrosion, proves itself suitable for deployment in challenging environments like oil refineries. Its exceptional resistance to corrosion, high temperatures, and chemical exposure plays a crucial role in the oil refining procedure. To ensure the longevity and functionality of refinery operations, stainless steel strips can be employed in various components of oil refinery equipment, including heat exchangers, pipes, tanks, and valves. Moreover, stainless steel's ease of cleaning and maintenance renders it the preferred choice in the oil refining industry.

- Q:How do stainless steel strips perform in high-temperature steam?

- Stainless steel strips are renowned for their exceptional performance in high-temperature steam settings. Thanks to their unique composition, these strips offer remarkable resistance to corrosion, even when confronted with aggressive steam conditions. The presence of chromium in stainless steel results in the formation of a protective layer of chromium oxide on the strip's surface. This layer acts as a formidable barrier, preventing corrosion and averting any interaction with the steam. Remarkably, this protective layer remains stable even under elevated temperatures, thus ensuring that the integrity and performance of the stainless steel strips are upheld in steam environments. Furthermore, the high strength and toughness of stainless steel strips enable them to withstand the mechanical stresses and pressures associated with high-temperature steam applications. In summary, stainless steel strips are a dependable and enduring choice for deployment in high-temperature steam environments, offering long-lasting performance and corrosion resistance.

- Q:Can stainless steel strips be used for automotive suspension components?

- Automotive suspension components can indeed utilize stainless steel strips. Renowned for its remarkable strength, resistance to corrosion, and durability, stainless steel proves to be a fitting material for diverse automotive uses, including suspension components. Springs, brackets, and other crucial parts necessary for the suspension system can be efficiently manufactured using stainless steel strips. These components must endure substantial loads, vibrations, and exposure to varying environmental conditions, and stainless steel's properties establish it as a dependable choice for such rigorous applications. Furthermore, the corrosion resistance of stainless steel guarantees an extended lifespan for suspension components, even in the face of harsh conditions. Thus, stainless steel strips present a practical alternative for automotive suspension components.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel Coil 201 Hot Rolled Narrow Coil J3

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords