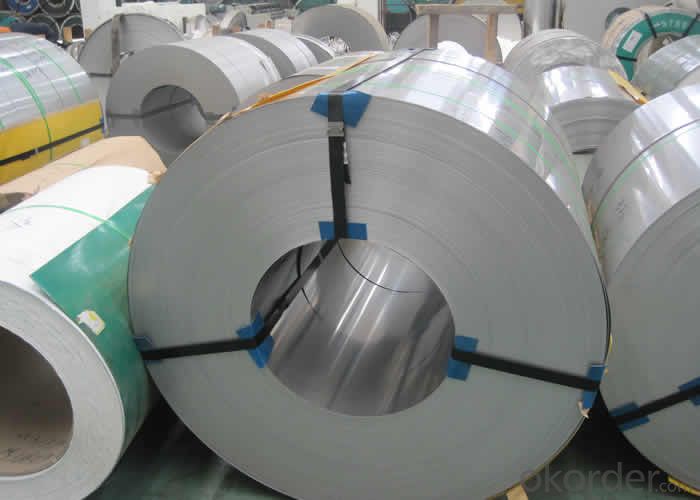

Stainless Steel Coil 201 Hot Rolled Coil Narrow Coil

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Rolled Stainless Steel Coil 201 Narrow Strip No.1 Finish

Packaging Detail: For customer's requirement

Delivery Detail: 10-30days

201 Hot Rolled Stainless Steel Coil Specifications

THK: 2.3/2.5/3.0/4.0mm

Width: 485/510/550/610/1010/1240mm

Face: No.1

201 Hot rolled stainless steel Coil Application

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely

used in light industry,heavy industry,daily necessities and the decoration industry.

201 Hot Stainless Steel Coil Chemical Composition(WT%)

(C):≤0.15, (Si):≤0.75, (Mn):5.5~7.50, (Cr):16.0~18.0, (N):≤0.25, (Ni):3.50~5.50, (P):≤0.060, (S):≤0.030

201 Hot Rolled Stainless Steel Coil

Strength Of Extension:100,000 To 180,000 Psi

Yield Strength:50,000 To 150,000 Psi

Elongation :55 To 60%

Modulus Of Elasticity:29,000,000 Psi

Density :.280lbs/Cubic Inch(7.93g/Cm3)

- Q:Are stainless steel strips suitable for wastewater treatment equipment?

- Yes, stainless steel strips are suitable for wastewater treatment equipment. Stainless steel is known for its corrosion resistance, durability, and ability to withstand harsh environments, making it an ideal choice for equipment that comes into contact with wastewater. It is also easy to clean and maintain, making it a practical option for wastewater treatment applications.

- Q:Can 111 stainless steel strips be used in the pulp and paper industry?

- In the pulp and paper industry, the utilization of 111 stainless steel strips is feasible. This industry extensively employs stainless steel due to its ability to resist corrosion, its robustness, and its durability. It serves various purposes, including the production of paper machines, screens, and other equipment that are exposed to corrosive chemicals and liquids utilized in the pulp and paper manufacturing process. The 111 grade stainless steel, known as AISI 111 or S11100, is a low carbon variant that demonstrates desirable weldability and resistance to intergranular corrosion. Hence, it presents itself as a suitable material choice for specific requirements in the pulp and paper industry. Nevertheless, it is vital to assess the application and conditions meticulously to ensure that the stainless steel strips satisfy the necessary mechanical and chemical properties for optimal performance.

- Q:What are the common uses of stainless steel strips in the oil refining process?

- The oil refining process relies on stainless steel strips for various purposes. Firstly, these strips are commonly employed in constructing storage tanks and pipelines. Due to its high resistance to corrosion, stainless steel can endure the harsh conditions and corrosive substances present in oil refining. This quality makes it an ideal choice for maintaining the integrity and durability of storage tanks and pipelines used for transporting crude oil and refined products. Moreover, stainless steel strips are frequently utilized in the fabrication of heat exchangers and condensers. These components have a critical role in the oil refining process, as they transfer heat and aid in the condensation of specific substances. Stainless steel's exceptional resistance to heat and its ability to conduct thermal energy efficiently make it suitable for these applications, ensuring efficient and dependable operation. Furthermore, stainless steel strips also play a vital role in manufacturing various types of equipment used in oil refining, such as pumps, valves, and fittings. These components must endure high pressures, temperatures, and aggressive chemicals. Due to stainless steel's strength, durability, and resistance to corrosion, it is an ideal material for such equipment, guaranteeing safe and efficient operation throughout the oil refining process. In conclusion, stainless steel strips serve a wide range of purposes in the oil refining process, including the construction of storage tanks and pipelines, the fabrication of heat exchangers and condensers, and the manufacturing of equipment like pumps, valves, and fittings. Its resistance to corrosion, heat, and strength make it an indispensable material for ensuring the reliability, efficiency, and safety of the oil refining industry.

- Q:What are the common uses of stainless steel strips in the power generation industry?

- Due to their exceptional properties and durability, stainless steel strips find extensive use in the power generation industry. Here, we present some prevalent applications of stainless steel strips in this sector: 1. Turbines: The construction of turbine blades and rotors relies heavily on stainless steel strips. These components require materials with high strength, corrosion resistance, and the ability to withstand elevated temperatures. Stainless steel emerges as the ideal choice, ensuring the generation of power efficiently and reliably. 2. Heat exchangers: The power generation process heavily relies on heat exchangers, making stainless steel strips indispensable. These strips exhibit remarkable resistance to corrosion and high temperatures, enabling efficient heat transfer between various fluids within power plants. 3. Boiler components: Various boiler components, such as tubes, flues, and pressure vessels, commonly employ stainless steel strips in their fabrication. These strips possess corrosion resistance, high-temperature strength, and low maintenance requirements, rendering them reliable and cost-effective for power generation applications. 4. Exhaust systems: To safely and efficiently channel exhaust gases out of power generation facilities, stainless steel strips are frequently utilized in exhaust system construction. Ductwork, stacks, and chimneys made from stainless steel strips offer corrosion resistance and high-temperature tolerance. 5. Condensers: In power plants, stainless steel strips are crucial for manufacturing condenser tubes. These tubes facilitate the efficient transfer of heat from steam to cooling water, ensuring optimal power generation. Stainless steel's resistance to corrosion and fouling makes it an ideal material for condenser tubes, guaranteeing long-lasting reliability and performance. By incorporating stainless steel strips into power generation equipment, the industry benefits from enhanced efficiency, reliability, and longevity. These strips' properties ensure safe operation in demanding environments, ultimately promoting sustainable electricity production.

- Q:Can stainless steel strips be used in chemical pumps?

- Indeed, chemical pumps can employ stainless steel strips for their operation. Stainless steel boasts remarkable resistance against corrosion and can endure exposure to a diverse array of chemicals. It finds widespread application in the fabrication of chemical pumps and other apparatuses that encounter corrosive substances. By utilizing stainless steel strips, the pump's robustness and longevity are secured, rendering it apt for handling a multitude of chemical variants.

- Q:What are the weight and density of stainless steel strips?

- The weight and density of stainless steel strips may vary based on the particular grade and thickness of the strips. However, in general, stainless steel is a dense material that surpasses the weight of numerous other metals. Stainless steel usually exhibits a density ranging from 7.75 to 8.05 grams per cubic centimeter, a considerably higher value compared to aluminum (2.7 g/cm³) or titanium (4.5 g/cm³). Regarding the weight of stainless steel strips, it relies on the strip's dimensions. To calculate the weight of a stainless steel strip, one must multiply the density of stainless steel by the volume of the strip. The strip's volume can be determined by multiplying its length, width, and thickness. Consequently, to accurately ascertain the weight and density of stainless steel strips, it is crucial to have knowledge about the specific grade and dimensions of the strips in question.

- Q:How do stainless steel strips resist oxidation?

- Stainless steel strips resist oxidation due to the presence of chromium in their composition. Chromium forms a thin, passive oxide layer on the surface of the steel, known as chromium oxide, which acts as a protective barrier against corrosion and oxidation. This oxide layer is self-healing, meaning that if it is scratched or damaged, it will reform and protect the steel again. Additionally, stainless steel also contains other alloying elements such as nickel and molybdenum, which further enhance its resistance to oxidation and corrosion. These elements help to stabilize the oxide layer and provide additional protection against harmful environmental factors such as moisture, acids, and chemicals. As a result, stainless steel strips can withstand exposure to various harsh conditions, preventing rust and maintaining their structural integrity over time.

- Q:What are the different types of edge finishes for stainless steel strips?

- Some common types of edge finishes for stainless steel strips include mill edge, slit edge, deburred edge, rounded edge, and beveled edge.

- Q:How do stainless steel strips perform in the presence of chlorine?

- Stainless steel strips generally perform well in the presence of chlorine. Stainless steel is known for its corrosion resistance properties, and it forms a passive chromium oxide layer on its surface that provides protection against oxidation and corrosion. This oxide layer acts as a barrier, preventing chlorine from reaching the underlying steel and causing corrosion. However, in certain conditions, stainless steel can still be susceptible to localized corrosion, such as pitting and crevice corrosion, in the presence of high concentrations of chlorine or in the presence of other corrosive agents. It is important to consider the specific grade of stainless steel being used, as some grades may have better resistance to chlorine than others. Additionally, proper maintenance and cleaning procedures should be followed to ensure the longevity and performance of stainless steel strips in chlorine-rich environments.

- Q:Are 111 stainless steel strips suitable for water treatment facilities?

- Yes, 111 stainless steel strips are suitable for water treatment facilities. Stainless steel is widely used in water treatment facilities due to its excellent corrosion resistance and durability. The 111 grade stainless steel, also known as AISI 444, is a ferritic stainless steel with high resistance to corrosion, especially in chloride environments. It is resistant to both organic and inorganic acids, making it suitable for handling various chemicals and water treatment processes. Additionally, stainless steel strips are easy to clean and maintain, which is crucial in water treatment facilities to ensure hygienic conditions. Therefore, 111 stainless steel strips are a suitable choice for water treatment facilities.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel Coil 201 Hot Rolled Coil Narrow Coil

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords