Stainless Steel 304L sheet and plate with low MOQ

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel 304L sheet and plate with low MOQ

Description of Stainless Steel 304L sheet and plate with low MOQ:

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widelyused in light industry,heavy industry,daily necessities and the decoration industry.my company long-termsupply stainless steel porducts including:stainless steel sheet,stainless steel coil and stainless steel tube.

Main Features of Stainless Steel 304L sheet and plate with low MOQ:

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Maintance of Stainless Steel 304L sheet and plate with low MOQ:

(1) Regular cleaning and maintenance

(2) Pay attention to prevent the occurrence of the phenomenon of surface scratches

(3) Use soap, weak detergent or warm water to remove surface dust, dirt

(4) In addition to the surface of the binder with alcohol or an organic solvent (ether, benzene)

(5) Use neutral detergent or ammonia solution in addition to surface oil

(6) With 10% nitric acid or abrasive detergent in addition to the surface of the embroider caused by the dirt.

Applications of Stainless Steel 304L sheet and plate with low MOQ:

Stainless steel’s resistance to corrosion and staining, low maintenance and familiar lustre make it an ideal material for many applications. There are over 150 grades of stainless steel, of which fifteen are most commonly used. The alloy is milled into coils, sheets, plates, bars, wire, and tubing to be used in cookware, cutlery, household hardware, surgical instruments, major appliances, industrial equipment Storage tanks and tankers used to transport orange juice and other food are often made of stainless steel, because of its corrosion resistance and antibacterial properties. This also influences its use in commercial kitchens and food processing plants, as it can be steamcleaned and sterilized and does not need paint or other surface finishes..

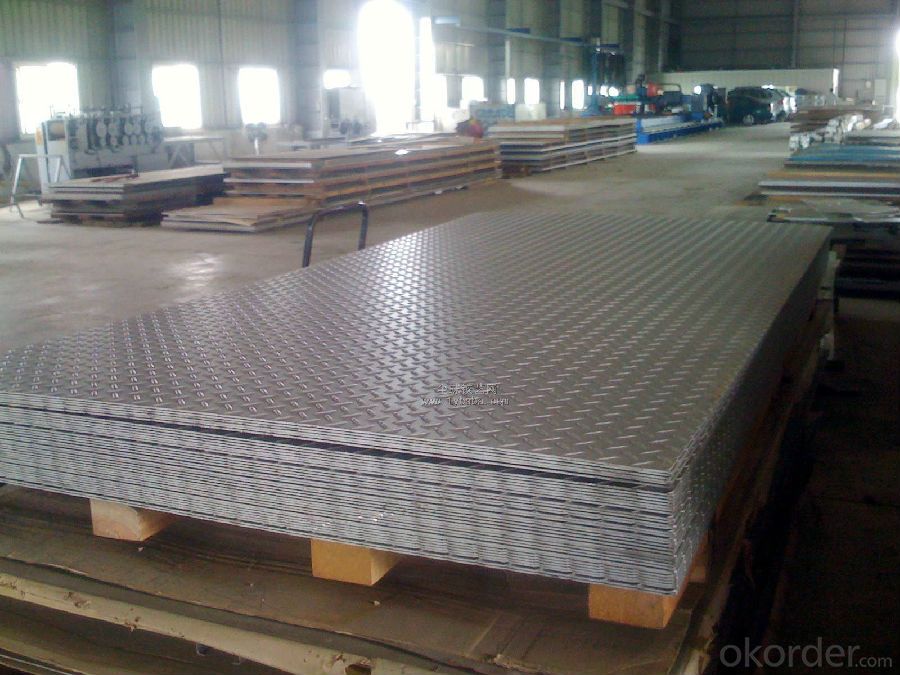

Specifications of Stainless Steel 304L sheet and plate with low MOQ:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

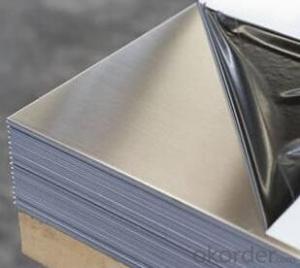

Surface Finish Characteristics of Stainless Steel 304L sheet and plate with low MOQ:

| Surface finish | Characteristics and application |

| 2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

| No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

| No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

| BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

| 8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Images of Stainless Steel 304L sheet and plate with low MOQ:

Sandard Seaworth Packing(wooden packing with water proof paper):

FAQ:

1. What are we supplying?

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a prelonged period. We are currently supplying grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321, 410/420/430/443/444/409L, and 904L.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

Our company adheres to the tenet of "survival by quality, build brand by reputation, win market by prices and innovate to develop", has developed international markets and the products are well sold in many countries as Singapore, Indonesia, South Korea, Dubai, Pakistan, Sri Lanka, Vietnam, Iran, Malaysia, Mexico, Chile, Brazil, Holland, Italy, Belgium, Russia, Moldova, Paraguay, Uruguay, Germany, Spain, USA etc. More than 40 countries.; commonly we have more than 500tons stainless steel materials in stock; so w can arrange the soonest delivery too; also we hope we will have chance to cooperate with your esteemed company!

- Q:Can stainless steel sheets be used for decorative elevator doors or panels?

- Indeed, stainless steel sheets are perfectly suitable for adorning elevator doors or panels in a decorative manner. The versatility of stainless steel as a material is unparalleled, as it not only bestows an exquisite and contemporary appearance but also enjoys great popularity for its decorative applications. Its exceptional durability, resistance to corrosion, and effortless maintenance make it an ideal choice for areas with heavy foot traffic, such as elevator doors and panels. Moreover, stainless steel sheets can be tailored to one's specific preferences by incorporating a wide range of finishes, patterns, and textures, thereby offering limitless design possibilities. Whether one desires a sleek and minimalist aesthetic or a more intricate and decorative motif, stainless steel sheets can elevate the visual appeal of elevator doors and panels while providing enduring functionality.

- Q:What is 3042B stainless steel?

- 304: general model, that is, 18/8 stainless steel. Products such as: corrosion-resistant containers, tableware, furniture, railings, medical equipment. The standard ingredient is 18% chromium plus 8% nickel. Stainless steel that is free of magnetism and can not be altered by heat treatment. GB is 0Cr18Ni9.

- Q:How do I clean and maintain stainless steel sheets?

- To clean and maintain stainless steel sheets, follow these simple steps: 1. Start by removing any loose dirt or debris from the surface using a soft cloth or sponge dampened with warm water. 2. For tougher stains or fingerprints, mix a mild detergent with warm water and apply it to the sheet using a non-abrasive sponge or cloth. Gently scrub the affected area in the direction of the grain. 3. Rinse the sheet thoroughly with clean water to remove any residue from the detergent. 4. Dry the stainless steel sheet with a soft cloth to prevent water spots or streaks from forming. 5. To maintain the shine and protect against future stains, apply a small amount of stainless steel cleaner or polish to a clean, soft cloth. Rub the surface in the direction of the grain, avoiding circular motions. 6. Wipe off any excess cleaner or polish with a separate clean cloth to ensure an even finish. 7. For stubborn stains or scratches, you can use a stainless steel cleaner that contains mild abrasives. However, be cautious as these products may scratch the surface if used improperly. 8. Avoid using abrasive sponges, steel wool, or harsh chemicals as they can damage the stainless steel surface. 9. Regularly dust the stainless steel sheets with a soft cloth to prevent the accumulation of dirt or dust particles. 10. Lastly, remember to always refer to the manufacturer's instructions for specific cleaning and maintenance recommendations for your particular stainless steel sheet product.

- Q:Are stainless steel sheets resistant to high temperatures?

- Yes, stainless steel sheets are generally resistant to high temperatures. Stainless steel is known for its excellent heat resistance properties, making it suitable for a wide range of high-temperature applications. The composition of stainless steel, which includes chromium, nickel, and other alloying elements, creates a protective oxide layer on its surface. This oxide layer acts as a barrier against oxidation and prevents the steel from corroding or weakening at elevated temperatures. Stainless steel sheets can withstand temperatures up to around 1500°F (815°C) without losing their structural integrity. However, the exact temperature resistance may vary depending on the specific grade and thickness of the stainless steel sheet. It is always recommended to consult the manufacturer's specifications or seek professional advice for specific high-temperature applications.

- Q:Can stainless steel sheets be used for outdoor sculptures?

- Indeed, outdoor sculptures can make use of stainless steel sheets. Due to its remarkable resistance to corrosion, stainless steel is exceptionally suitable for outdoor scenarios where sculptures are subjected to diverse weather conditions. It can endure rain, snow, heat, and UV radiation without compromising its strength or deteriorating. Moreover, stainless steel boasts a sleek and contemporary appearance that can augment the sculpture's visual impact. Its robustness and ability to repel rust render it a favored selection for outdoor sculptures found in parks, gardens, and public areas.

- Q:Can stainless steel sheets be used for solar panels?

- Yes, stainless steel sheets can be used for solar panels. Stainless steel is a durable and corrosion-resistant material that can protect the solar panels from environmental conditions. It is commonly used as a backing material or frame for solar panels due to its strength and longevity.

- Q:Are stainless steel sheets suitable for architectural designs?

- Yes, stainless steel sheets are suitable for architectural designs. Stainless steel is a versatile material that offers a wide range of benefits for architectural projects. Its durability and resistance to corrosion make it ideal for both indoor and outdoor applications. Additionally, stainless steel sheets can be easily fabricated into various shapes and sizes, allowing architects to create unique and visually appealing designs. The sleek and modern appearance of stainless steel adds an aesthetic appeal to buildings, making it a popular choice in contemporary architecture. Furthermore, stainless steel is a sustainable material as it is 100% recyclable, making it an environmentally friendly choice for architectural designs. Overall, stainless steel sheets offer numerous advantages that make them highly suitable for architectural designs.

- Q:How do you polish stainless steel sheets?

- To polish stainless steel sheets, you can follow a few simple steps. First, ensure that the surface is clean and free from any dirt or debris. You can use a mild detergent or stainless steel cleaner to remove any stains or marks. Next, use a soft cloth or sponge to apply a stainless steel polish or a combination of vinegar and olive oil. Apply the polish in the direction of the grain, which is usually a linear pattern on the surface of stainless steel. Once the polish is applied, use another clean cloth to buff the surface in the same direction as the grain. Apply gentle pressure and continue buffing until the stainless steel sheets start to shine and appear polished. If necessary, repeat the process in areas that require additional polishing, and ensure that all excess polish is wiped away to avoid streaks or residue. It is important to note that different stainless steel finishes may require specific polishing techniques or products. Always refer to the manufacturer's instructions or guidelines for best results.

- Q:What are the different types of colored finishes available for stainless steel sheets?

- Some of the different types of colored finishes available for stainless steel sheets include brushed, mirrored, satin, and antique finishes. Additionally, there are options for powder coating, electroplating, and PVD (physical vapor deposition) coatings that can offer various colors and patterns to enhance the appearance of stainless steel sheets.

- Q:What is the difference between stainless steel sheets and plates?

- Stainless steel sheets and plates are both types of flat metal materials that are widely used in various industries and applications. However, there are a few key differences between them. 1. Thickness: Stainless steel sheets are generally thinner than plates. Sheets typically have a thickness ranging from 0.4mm to 4mm, whereas plates are usually thicker, starting from 4mm and going up to several inches. 2. Size: Sheets are typically available in standard sizes of 4ft x 8ft or 5ft x 10ft, while plates are usually available in larger sizes and can be customized to specific dimensions. Plates are commonly used for heavy-duty applications that require greater strength and durability. 3. Weight: Due to their difference in thickness, plates are generally heavier than sheets. This makes plates more suitable for applications where weight-bearing capacity is critical, such as construction, shipbuilding, or industrial equipment. 4. Applications: Stainless steel sheets are commonly used for decorative purposes, architectural applications, and smaller-scale projects such as kitchen backsplashes or countertops. Plates, on the other hand, are preferred for structural components, machinery parts, and load-bearing applications like bridges, tanks, or pressure vessels. 5. Cost: Stainless steel plates are generally more expensive than sheets due to their larger size and higher thickness. Sheets, being thinner and smaller, are usually more cost-effective and easily accessible. In summary, the key differences between stainless steel sheets and plates are their thickness, size, weight, applications, and cost. It is important to consider these factors when choosing between the two materials for a specific project or application.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel 304L sheet and plate with low MOQ

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords