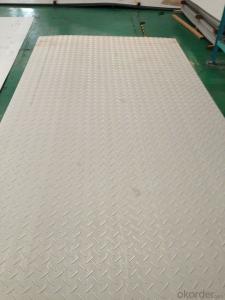

Stainless Steel 304 sheet with top quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stainless steel 304 sheet

Company advantage of stainless steel:

-Top Equipments, Leading In The Industry.

- Professional Team, Leading Innovation.

- Huge Supply Capacity Advantage, Timely and Effective Delivery.

- Modern Logistic, Fact and Convenient.

- Precise Manufacturing, Exquisite Products.

- Serve People, Create Value.

- Dimensional Network, Powerful Expansion.

Product Information of stainless steel sheet:

- Q:What is the difference between 321 and 321H stainless steel pipes?

- The main difference between 321 and 321H stainless steel pipes lies in their carbon content. 321H contains a higher amount of carbon, which improves its high-temperature strength and resistance to sensitization during welding. This makes 321H more suitable for applications requiring elevated temperatures, while 321 is typically used in lower temperature environments.

- Q:Can stainless steel pipes be chromed?

- Indeed, it is possible to chrome stainless steel pipes. To achieve this, a layer of chromium is applied onto the surface of the stainless steel pipe through a process called chrome plating. Typically, this involves immersing the stainless steel pipe in a solution containing chromium salts, while an electric current is passed through the bath. As a result, the chromium adheres to the surface of the stainless steel pipe. This chrome plating not only enhances the appearance of the stainless steel pipe but also provides a protective finish, increasing its resistance to corrosion and wear.

- Q:What is the difference between 430 and 316 stainless steel pipes?

- The main difference between 430 and 316 stainless steel pipes lies in their composition and properties. 430 stainless steel is a ferritic stainless steel that contains chromium, which gives it good corrosion resistance. However, it is not as resistant to corrosion as 316 stainless steel. It also has lower nickel content compared to 316 stainless steel. On the other hand, 316 stainless steel is an austenitic stainless steel that contains both chromium and nickel. It has excellent corrosion resistance, making it suitable for various applications, including marine environments, where it is exposed to saltwater and other corrosive substances. It also has higher tensile strength and creep resistance compared to 430 stainless steel. In terms of appearance, 430 stainless steel has a dull, brushed finish, while 316 stainless steel has a bright, reflective finish. Considering these differences, the choice between 430 and 316 stainless steel pipes depends on the specific application and the level of corrosion resistance required.

- Q:Can stainless steel pipes be insulated with mineral wool?

- Yes, stainless steel pipes can be insulated with mineral wool. Mineral wool is a common insulating material that can be used on various types of pipes, including stainless steel. It provides thermal insulation and helps to prevent heat loss or gain, depending on the application.

- Q:How do you calculate the maximum allowable deflection for stainless steel pipes?

- The maximum allowable deflection for stainless steel pipes can be calculated using the formula provided by the applicable industry standards or codes, such as ASME B31.3 for process piping or ASME B31.1 for power piping. These standards consider factors such as the pipe material, diameter, wall thickness, temperature, pressure, and support conditions to determine the maximum allowable deflection. It is essential to consult the relevant standards or seek guidance from a qualified engineer to accurately calculate the maximum allowable deflection for stainless steel pipes.

- Q:What is the difference between electropolished and passivated stainless steel pipes?

- Both electropolished and passivated stainless steel pipes are utilized as surface treatments in order to enhance the corrosion resistance and aesthetic appearance of stainless steel. Nevertheless, there exist notable distinctions between the two procedures. Electropolishing serves as an electrochemical method which selectively eradicates a minute layer of material from the surface of the stainless steel. This process aids in eliminating impurities, contaminants, and embedded particles, thereby resulting in a sleek and pristine surface. Furthermore, electropolishing enhances the microfinish of the stainless steel, thereby reducing surface roughness and elevating the overall appearance. It also augments the corrosion resistance of stainless steel by fostering the formation of a passive chromium oxide layer on the surface. Conversely, passivation is a chemical process that involves the application of an acid-based solution onto the surface of the stainless steel. This solution assists in eliminating iron contaminants and other foreign substances from the surface, leaving behind a spotless and passive layer of chromium oxide. Passivation serves to enhance the corrosion resistance of stainless steel by promoting the creation of a stable and protective oxide layer. In conclusion, electropolishing represents an electrochemical approach that eradicates a thin layer of material, thereby generating a smooth and pristine surface, whereas passivation constitutes a chemical process that eliminates contaminants and encourages the development of a safeguarding oxide layer. Both procedures contribute to heightening the corrosion resistance and aesthetics of stainless steel pipes, although they differ in the methodologies employed to achieve these outcomes.

- Q:Can stainless steel pipes be used for wastewater treatment?

- Stainless steel pipes are indeed suitable for wastewater treatment. This material, known for its resistance to corrosion, brings numerous advantages to applications in wastewater treatment. It is highly durable and can withstand exposure to aggressive chemicals and abrasive substances typically found in wastewater. Moreover, stainless steel pipes do not rust, ensuring a longer lifespan and minimizing the chances of pipe failure. In addition, stainless steel is inert and non-reactive, making it ideal for transporting and containing various types of wastewater without any risk of contamination. The smooth surface of stainless steel pipes also prevents the accumulation of deposits and biofilm, reducing the likelihood of clogging and allowing for the efficient flow of wastewater. All in all, stainless steel pipes present a dependable and sustainable choice for wastewater treatment systems.

- Q:Can stainless steel pipes be coated for additional protection?

- Yes, stainless steel pipes can be coated for additional protection. Coatings can provide various benefits such as corrosion resistance, improved durability, and enhanced aesthetic appearance. The most commonly used coating for stainless steel pipes is a polymer-based coating, which acts as a barrier against external elements and prevents corrosion. Other types of coatings, such as epoxy or zinc coatings, can also be applied to stainless steel pipes to provide additional protection. The choice of coating depends on the specific requirements and environmental conditions the pipes will be exposed to. Coating stainless steel pipes can help extend their lifespan and ensure optimal performance in various applications, including industrial and residential plumbing systems.

- Q:How do stainless steel pipes compare to other materials like copper or PVC?

- Stainless steel pipes possess numerous advantages when compared to other materials such as copper or PVC. To begin with, stainless steel exhibits exceptional resistance to both corrosion and rust, rendering it suitable for a variety of applications, especially in environments characterized by high moisture or chemical exposure. Conversely, copper pipes are prone to corrosion over time and may necessitate additional protective coatings or treatments. Moreover, stainless steel pipes boast remarkable strength and durability, enabling them to withstand high pressure and temperature conditions. PVC pipes, despite being lightweight and easy to install, do not possess the same level of strength as stainless steel and may crack or deform under extreme circumstances. An additional benefit of stainless steel pipes lies in their ability to accommodate a wide variety of fluids, including corrosive substances and high-temperature liquids. Conversely, PVC pipes have limited compatibility and may not be suitable for certain applications that demand resistance to chemicals or extreme temperatures. Furthermore, stainless steel pipes offer superior fire resistance in comparison to PVC pipes, which are highly flammable and emit toxic fumes when exposed to fire. Consequently, stainless steel pipes serve as a safer alternative, particularly in buildings or industries where fire safety is of utmost importance. Lastly, stainless steel pipes possess a longer lifespan when compared to copper or PVC pipes. While copper pipes may develop leaks or pinholes over time, and PVC pipes may become brittle and crack, stainless steel pipes are engineered to endure for decades with minimal maintenance. In conclusion, stainless steel pipes represent a dependable and durable choice for an array of applications due to their corrosion resistance, strength, versatility, fire resistance, and prolonged lifespan. They outperform copper and PVC pipes in terms of durability, compatibility, safety, and overall performance, thus establishing themselves as an excellent option for numerous industries and applications.

- Q:Can stainless steel pipes be used for desalination plants?

- Yes, stainless steel pipes can be used for desalination plants. Stainless steel is a highly corrosion-resistant material, which makes it suitable for use in desalination plants where the water contains high levels of salt and other corrosive substances. The high corrosion resistance of stainless steel pipes helps to prevent the buildup of scale and the formation of rust, ensuring the longevity and efficiency of the desalination plant. Additionally, stainless steel pipes are also known for their high strength and durability, which can withstand the high pressure and temperature conditions often found in desalination plants. Overall, stainless steel pipes are an ideal choice for desalination plants due to their corrosion resistance, strength, and durability.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel 304 sheet with top quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords