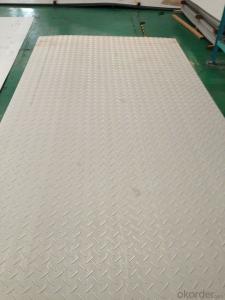

Stainless Steel 304 sheet with innovative technology

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stainless steel 304 sheet

Company advantage of stainless steel:

-Top Equipments, Leading In The Industry.

- Professional Team, Leading Innovation.

- Huge Supply Capacity Advantage, Timely and Effective Delivery.

- Modern Logistic, Fact and Convenient.

- Precise Manufacturing, Exquisite Products.

- Serve People, Create Value.

- Dimensional Network, Powerful Expansion.

Product Information of stainless steel sheet:

- Q:Can stainless steel pipes be used for high-pressure applications?

- Yes, stainless steel pipes can be used for high-pressure applications. Stainless steel is known for its excellent strength and corrosion resistance, making it suitable for handling high-pressure environments. It can withstand the high pressure without deformation or leakage, ensuring the safety and reliability of the system.

- Q:What is the difference between 316 and 316Ti stainless steel pipes?

- The carbon content is the main distinguishing factor between 316 and 316Ti stainless steel pipes. Although both grades are highly resistant to corrosion and suitable for various applications, 316Ti contains a small amount of titanium that enhances its resistance to sensitization. Sensitization occurs when stainless steel is heated between 500-900°C, resulting in the formation of chromium carbides that can cause intergranular corrosion. 316Ti stainless steel pipes prevent the formation of these carbides by reacting with carbon, thus maintaining their corrosion resistance even at high temperatures. This characteristic makes 316Ti pipes more suitable for applications involving elevated temperatures or prolonged exposure to corrosive environments. In terms of mechanical properties, both grades exhibit similar strength and toughness. However, 316Ti may have slightly lower ductility compared to 316 due to the addition of titanium. It's worth noting that the difference in carbon content between these two grades is minimal, typically less than 0.08%. To summarize, the inclusion of titanium in 316Ti stainless steel pipes enhances their resistance to sensitization and intergranular corrosion, making them a preferred choice for applications involving high temperatures or corrosive environments.

- Q:What are the different types of stainless steel pipe end connections?

- There are several different types of stainless steel pipe end connections, each designed for specific applications and requirements. Some of the most common types include: 1. Threaded connections: This type of connection features threads on the inside or outside of the pipe end, allowing it to be screwed onto another threaded fitting or pipe. Threaded connections are typically used for low-pressure applications. 2. Socket-weld connections: In this type of connection, the pipe end is inserted into a socket or recess of a socket-weld fitting and then welded around the outside of the pipe. Socket-weld connections are suitable for high-pressure applications and are known for their strength and reliability. 3. Butt-weld connections: Butt-weld connections involve welding the pipe end directly to another pipe or fitting. They are commonly used in high-pressure and high-temperature applications. 4. Flanged connections: Flanged connections feature a flange on the pipe end, which is then bolted to a mating flange on another pipe or fitting. Flanged connections are used in applications requiring easy disassembly or where there is a need for frequent maintenance. 5. Compression connections: Compression connections involve using a compression fitting to join the pipe ends. These connections are commonly used in plumbing and gas supply systems and are known for their ease of installation. 6. Grooved connections: Grooved connections involve using grooved couplings to join the pipe ends. These connections are often used in fire protection systems and are known for their quick and simple installation. Overall, the choice of stainless steel pipe end connection depends on the specific application, pressure requirements, ease of installation, and maintenance considerations. It is important to consult with a professional or refer to industry standards to determine the most suitable connection type for your particular needs.

- Q:Can stainless steel pipes be insulated with fiberglass?

- Fiberglass insulation is a viable option for insulating stainless steel pipes. Its exceptional thermal resistance characteristics make it a popular choice for pipe insulation. By preventing heat loss or gain, it enhances energy efficiency. Moreover, fiberglass insulation is lightweight, simple to install, and can be easily customized to fit pipes of different sizes and shapes. It also offers excellent sound insulation properties and is non-combustible. Thus, fiberglass insulation is the ideal solution for insulating stainless steel pipes.

- Q:What is the maximum length of stainless steel pipes?

- The maximum length of stainless steel pipes can vary depending on various factors such as the manufacturing process, the specific grade of stainless steel used, and the intended application. In general, stainless steel pipes can be manufactured in lengths ranging from a few feet to several hundred feet. However, it is important to note that longer lengths may require special handling during transportation and installation due to their weight and potential for bending or damage. Additionally, certain applications may have specific limitations on the maximum length of stainless steel pipes to ensure optimal performance and safety.

- Q:What is the difference between seamless and hot-finished stainless steel pipes?

- Seamless stainless steel pipes are manufactured without any welding seams, resulting in a smooth and uniform appearance. They are made by piercing a solid billet of stainless steel and then extruding it into a hollow tube shape. On the other hand, hot-finished stainless steel pipes are made by heating a solid billet and then rolling it into a tube shape while hot. This process may result in visible welding seams, but the pipes are still durable and suitable for various applications.

- Q:What are stainless steel pipes used for?

- Various industries widely use stainless steel pipes because of their exceptional durability, resistance to corrosion, and high strength. These pipes have extensive applications in plumbing systems, oil and gas industries, chemical processing plants, food and beverage processing, pharmaceutical industries, and automotive manufacturing, among others. Plumbing systems favor stainless steel pipes due to their ability to withstand high pressure and temperature, making them suitable for transporting water, gas, and other fluids. They are also commonly used in sewage and drainage systems because of their resistance to corrosion and chemical substances. In the oil and gas industries, stainless steel pipes are indispensable for transporting petroleum products, natural gas, and other fluids under high pressure and extreme temperatures. Their corrosion resistance properties make them essential in offshore and onshore drilling operations, refineries, and petrochemical plants, ensuring the safe and efficient transportation of these substances. Chemical processing plants rely on stainless steel pipes because of their resistance to chemical reactions and high temperatures. These pipes are used to transport various corrosive chemicals and gases without the risk of contamination or leakage. Additionally, they are utilized in heat exchangers, reactors, and other equipment that require corrosion-resistant materials. The food and beverage industry heavily relies on stainless steel pipes due to their hygiene and sanitary properties. These pipes are used for conveying various food products, such as milk, wine, beer, and other liquids, without altering their taste or quality. They are easy to clean, maintain, and sterilize, making them ideal for this industry. In the pharmaceutical sector, stainless steel pipes play a crucial role in conveying various drugs, chemicals, and sterile fluids. They meet the stringent requirements of the industry by ensuring product purity, preventing contamination, and offering resistance to corrosion and temperature extremes. Furthermore, stainless steel pipes are utilized in automotive manufacturing because of their structural strength and resistance to heat and corrosion. They are used in exhaust systems, fuel lines, and other components where durability and resistance to extreme conditions are necessary. In conclusion, stainless steel pipes are versatile and essential in numerous industries, providing the perfect combination of strength, durability, and corrosion resistance required for a wide range of applications.

- Q:304 stainless steel pipe, 20*2 pressure, how many kilograms?

- 304 stainless steel is a brand of stainless steel produced according to the ASTM standard in the United states. 304 is equivalent to 0Cr19Ni9 in our country(0Cr18Ni9) stainless steel. 304 chromium 19%, containing nickel 9%. The 304 is the most widely used stainless steel, heat-resistant steel, steel, steel industry utility. For food production equipment, general chemical equipment, nuclear energy, etc..

- Q:Can stainless steel pipes be used for pharmaceutical processing equipment?

- Yes, stainless steel pipes can be used for pharmaceutical processing equipment. Stainless steel is a preferred material in the pharmaceutical industry due to its excellent corrosion resistance, durability, and ease of cleaning. It is resistant to chemicals, corrosion, and high temperatures, making it suitable for handling and transporting various pharmaceutical substances. Additionally, stainless steel pipes have a smooth surface that minimizes the risk of contamination and allows for easy cleaning and sterilization. Overall, stainless steel pipes are widely used in pharmaceutical processing equipment to ensure the integrity and quality of pharmaceutical products.

- Q:Can stainless steel pipes be used for sewage pumping stations?

- Indeed, sewage pumping stations can utilize stainless steel pipes. Renowned for their resistance to corrosion, stainless steel proves to be an optimal material for sewage and wastewater applications. These pipes exhibit durability and strength, enabling them to endure the challenging circumstances and corrosive components present within sewage systems. Moreover, stainless steel exemplifies hygienic qualities and simplicity in cleaning, vital aspects for upholding the sanitation and effectiveness of a sewage pumping station. Consequently, stainless steel pipes establish themselves as a dependable and enduring selection for sewage pumping stations.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel 304 sheet with innovative technology

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords