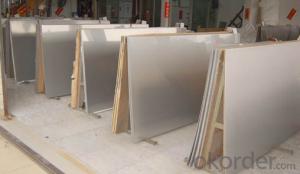

Stainless Steel 304 sheet with competitive pricing and top quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stainless steel 304 sheet

Company advantage of stainless steel:

-Top Equipments, Leading In The Industry.

- Professional Team, Leading Innovation.

- Huge Supply Capacity Advantage, Timely and Effective Delivery.

- Modern Logistic, Fact and Convenient.

- Precise Manufacturing, Exquisite Products.

- Serve People, Create Value.

- Dimensional Network, Powerful Expansion.

Product Information of stainless steel sheet:

- Q:What are the different finishes available for stainless steel pipes?

- There are several different finishes available for stainless steel pipes, each offering its own unique look and level of corrosion resistance. 1. Brushed Finish: This finish is achieved by brushing the surface of the stainless steel pipe with a fine abrasive material, resulting in a dull, textured appearance. It effectively hides scratches and fingerprints, making it a popular choice for applications where aesthetics are important, such as architectural projects. 2. Mirror Finish: Also known as a polished or reflective finish, this is achieved by polishing the surface of the stainless steel pipe to a high shine. It provides a smooth, reflective surface that is easy to clean and is commonly used in decorative applications, such as handrails and furniture. 3. Satin Finish: Similar to the brushed finish, the satin finish is achieved by using a fine abrasive material to create a smooth, dull appearance. It offers a slightly more refined look compared to the brushed finish and is commonly used in applications where corrosion resistance is important, such as in the food and beverage industry. 4. Embossed Finish: This finish involves imprinting a pattern onto the surface of the stainless steel pipe, adding texture and visual interest. It is often used in decorative applications, such as wall panels or elevator interiors. 5. Bead Blasted Finish: This finish is achieved by propelling small glass beads at high pressure onto the surface of the stainless steel pipe. It creates a uniform, matte appearance and is commonly used in architectural applications, as it provides a unique texture and hides fingerprints well. 6. Passivated Finish: Passivation is a chemical process that removes contaminants from the surface of the stainless steel pipe, improving its corrosion resistance. This finish is commonly used in applications where stainless steel pipes are exposed to harsh environments or chemicals. It is important to note that the choice of finish for stainless steel pipes depends on the specific application and aesthetic preferences. Each finish has its own advantages and disadvantages, so it is essential to consider factors such as durability, maintenance, and the intended use of the pipe before making a decision.

- Q:Can stainless steel pipes be chromed?

- Yes, stainless steel pipes can be chromed. The process involves applying a thin layer of chromium onto the surface of the stainless steel pipes, which not only enhances their appearance but also provides increased resistance to corrosion.

- Q:Can stainless steel pipes be used for pulp and paper mills?

- Pulp and paper mills can indeed utilize stainless steel pipes. Stainless steel possesses outstanding resistance against corrosion, as well as remarkable strength and durability. Consequently, it becomes an optimal selection for piping systems operating in harsh environments such as pulp and paper mills. The conventional pipes tend to deteriorate due to the acidic and corrosive properties of the chemicals employed in the paper-making process; however, stainless steel pipes can withstand these conditions without compromising their structural integrity. Furthermore, stainless steel pipes are easily cleanable and maintainable, which proves to be vital in industries where hygiene holds utmost significance. Thus, stainless steel pipes emerge as a dependable and long-lasting solution for fulfilling the piping requirements of pulp and paper mills.

- Q:Are stainless steel pipes suitable for fire sprinkler systems?

- Yes, stainless steel pipes are suitable for fire sprinkler systems. They offer excellent corrosion resistance, durability, and strength, making them an ideal choice for such systems. Stainless steel pipes can withstand high temperatures and maintain their structural integrity, ensuring reliable performance in fire emergencies.

- Q:How do stainless steel pipes compare to PVC-coated steel pipes?

- Stainless steel pipes and PVC-coated steel pipes have distinct differences in terms of material composition, durability, corrosion resistance, cost, and specific applications. Firstly, stainless steel pipes are made from a combination of iron and chromium, which provides excellent corrosion resistance and durability. This makes them suitable for applications in harsh environments, such as industrial settings or marine applications. On the other hand, PVC-coated steel pipes are made from steel coated with a layer of polyvinyl chloride (PVC). While PVC provides some level of corrosion resistance, it is not as durable as stainless steel and may degrade over time, especially in high-temperature or corrosive environments. In terms of durability, stainless steel pipes have a longer lifespan compared to PVC-coated steel pipes. Stainless steel is highly resistant to rust, corrosion, and chemical damage, ensuring long-term reliability. PVC-coated steel pipes, although corrosion-resistant to some extent, are more prone to damage from exposure to sunlight, extreme temperatures, or chemicals. When it comes to cost, PVC-coated steel pipes are generally more affordable compared to stainless steel pipes. This makes them a cost-effective option for applications that do not require high levels of durability or corrosion resistance. Stainless steel pipes, while more expensive upfront, offer a better return on investment due to their longer lifespan and reduced maintenance costs. The specific application also plays a crucial role in determining which type of pipe is most suitable. Stainless steel pipes are commonly used in industries such as oil and gas, chemical processing, food processing, and water treatment, where high strength, corrosion resistance, and hygiene are essential. PVC-coated steel pipes find application in areas such as underground drainage, irrigation systems, and electrical conduit, where cost-effectiveness and moderate durability are more important than extreme corrosion resistance. In summary, stainless steel pipes outperform PVC-coated steel pipes in terms of durability, corrosion resistance, and lifespan. However, PVC-coated steel pipes offer a more cost-effective solution for applications that do not require the same level of durability or corrosion resistance. Ultimately, the choice between these two types of pipes depends on the specific needs of the project, including its intended application, budget, and environmental conditions.

- Q:Why is the outer diameter of 1 inch galvanized pipe 33.7? And the outer diameter of one inch stainless steel pipe is 25.4

- Some 25.4 such outer threads, is the imperial Whitworth Thread and American Standard unified thread, single head wire estimate.

- Q:How are stainless steel pipes resistant to corrosion?

- Stainless steel pipes are resistant to corrosion due to the presence of an alloying element called chromium. Chromium forms a thin layer of chromium oxide on the surface of the steel, which acts as a protective barrier, preventing the steel from coming into direct contact with corrosive materials and environments. This oxide layer is highly durable and self-healing, providing long-term corrosion resistance to stainless steel pipes.

- Q:Can stainless steel pipes be used for underground sewer lines?

- Yes, stainless steel pipes can be used for underground sewer lines. Stainless steel is highly resistant to corrosion and is a durable material, making it suitable for underground applications where the pipes may come into contact with moisture, chemicals, and other harsh elements. Additionally, stainless steel pipes have a long lifespan and require minimal maintenance, making them a reliable choice for underground sewer lines.

- Q:How do stainless steel pipes compare to PEX pipes?

- Stainless steel pipes and PEX pipes have different characteristics and applications. Stainless steel pipes are known for their strength, durability, and resistance to corrosion, making them ideal for high-pressure and high-temperature applications. They are commonly used in industrial settings and for water supply systems. On the other hand, PEX pipes are flexible, lightweight, and easy to install, making them suitable for residential plumbing systems. PEX pipes have good resistance to freezing and are less prone to leaks compared to other materials. Ultimately, the choice between stainless steel and PEX pipes depends on the specific needs and requirements of the project.

- Q:Can stainless steel pipes be used in high-pressure applications?

- Yes, stainless steel pipes can be used in high-pressure applications. Stainless steel is known for its strength, durability, and ability to withstand extreme pressure conditions. It is often used in industries such as oil and gas, chemical processing, and power generation, where high-pressure environments are common. Stainless steel pipes offer excellent resistance to corrosion, making them suitable for long-term use in high-pressure applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel 304 sheet with competitive pricing and top quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords