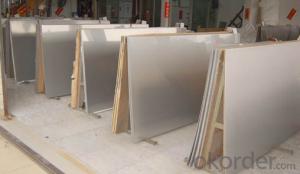

Stainless Steel 304 sheet from China top manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stainless steel 304 sheet

Company advantage of stainless steel:

-Top Equipments, Leading In The Industry.

- Professional Team, Leading Innovation.

- Huge Supply Capacity Advantage, Timely and Effective Delivery.

- Modern Logistic, Fact and Convenient.

- Precise Manufacturing, Exquisite Products.

- Serve People, Create Value.

- Dimensional Network, Powerful Expansion.

Product Information of stainless steel sheet:

- Q:Can stainless steel pipes be used in the mining industry?

- Yes, stainless steel pipes can be used in the mining industry. Stainless steel is highly resistant to corrosion, making it suitable for handling various chemicals and minerals found in mining operations. Additionally, its strength and durability make it capable of withstanding the harsh and demanding conditions often encountered in the mining industry.

- Q:What is the weight of stainless steel pipes?

- The weight of stainless steel pipes can vary depending on their length, diameter, and wall thickness. Stainless steel is a dense material, so stainless steel pipes are generally heavier compared to pipes made from other materials. The weight of stainless steel pipes is usually measured in kilograms or pounds per meter or per foot. It is important to note that the weight will differ based on the specific grade of stainless steel used in the production of the pipes.

- Q:Can stainless steel pipes be used for pharmaceutical manufacturing?

- Yes, stainless steel pipes can be used for pharmaceutical manufacturing. Stainless steel is a commonly used material in the pharmaceutical industry due to its excellent corrosion resistance, high strength, and ease of sterilization. It is suitable for transporting various pharmaceutical fluids and gases while ensuring cleanliness, safety, and compliance with industry regulations.

- Q:What is the lifespan of stainless steel pipes?

- The lifespan of stainless steel pipes can vary depending on various factors such as the grade of stainless steel used, the environment in which they are installed, and the maintenance practices followed. However, in general, stainless steel pipes have a long lifespan and can last for several decades or even longer with proper care and maintenance.

- Q:What is the difference between the stainless steel tube and tube rolling

- Stainless steel stands for material. According to the production process, steel pipe, sub welded pipe, hot rolled pipe, cold rolled pipe and cold drawn pipe. What you say should refers to the cold drawn pipe drawing. Pipe called cold drawn, round steel called cold drawn. Compared with these processes, cold drawing and cold rolling are close to each other. The accuracy is higher, because of the plastic deformation, the mechanical properties are better. The specific difference is that the cold rolling is less than the cold drawn processing track, the accuracy and surface roughness are higher, and the processing cost is high. Cold drawing hardness is high, processing cost is low, processing will be wasted.

- Q:Can stainless steel pipes be used for underground drainage systems?

- Indeed, underground drainage systems can utilize stainless steel pipes. Stainless steel proves to be a robust and corrosion-resistant substance capable of enduring the harsh conditions commonly encountered beneath the surface, encompassing moisture, soil chemicals, and fluctuating temperatures. Furthermore, stainless steel pipes exhibit resistance to rust, a prevalent issue faced by alternative pipe materials. Moreover, their extended lifespan and minimal maintenance demands render stainless steel pipes a fitting selection for underground drainage systems.

- Q:Are stainless steel pipes suitable for underground installations?

- Yes, stainless steel pipes are suitable for underground installations. Stainless steel is highly resistant to corrosion and can withstand harsh underground conditions such as moisture, soil chemicals, and temperature variations. Additionally, stainless steel pipes have high strength and durability, making them a reliable choice for underground applications.

- Q:What is the difference between Schedule and Nominal Pipe Sizes for stainless steel pipes?

- Stainless steel pipes can be described using Schedule and Nominal Pipe Sizes, but they have different focuses. Schedule denotes the pipe's wall thickness and is represented by a number. It is a standardized system used to classify pipes based on their wall thickness. The schedule number indicates how thick the pipe is in relation to its diameter. For instance, a Schedule 40 pipe has a thicker wall than a Schedule 10 pipe of the same diameter. The higher the schedule number, the thicker the wall. On the contrary, Nominal Pipe Size (NPS) represents the approximate inner diameter of the pipe and is expressed in inches. NPS is a size designation that doesn't directly correspond to the actual dimensions of the pipe. It serves as a convenient reference for identifying pipes and is often used in conjunction with the schedule number to specify a specific pipe. In summary, the main distinction between Schedule and Nominal Pipe Sizes for stainless steel pipes lies in what they describe. Schedule indicates the wall thickness, whereas Nominal Pipe Size refers to the approximate inner diameter of the pipe. Both factors are crucial when selecting the appropriate stainless steel pipe for a particular application.

- Q:What are the different types of stainless steel pipe hangers?

- There is a variety of stainless steel pipe hangers available, each designed for specific applications and needs. Some commonly used types include: 1. Split ring hangers: These hangers consist of a split ring that wraps around the pipe to provide support and stability. They are easy to install and adjust, making them suitable for pipes of different sizes. 2. Clevis hangers: Clevis hangers feature a U-shaped bracket that attaches to the pipe using a clevis pin. They have a high load-bearing capacity and are commonly used for vertical pipe installations. 3. Swivel ring hangers: Swivel ring hangers are designed to allow the pipe to move freely, accommodating thermal expansion and contraction. They have a circular ring that can rotate, reducing stress on the pipe. 4. Riser clamps: Riser clamps are used to support vertical pipes that run along walls or beams. They come in various designs and can be adjusted to fit different pipe sizes and configurations. 5. Beam clamps: Beam clamps are used to secure pipes to overhead beams or structures. They typically have a bolt or threaded rod that attaches the clamp to the beam, providing a secure mounting point. 6. Pipe rollers: Pipe rollers support pipes that need horizontal movement, such as sliding or rolling applications. They consist of rollers or wheels that allow the pipe to move smoothly. 7. Pipe straps: Pipe straps are simple and cost-effective hangers that wrap around the pipe and attach to a surface using screws or bolts. They are commonly used for light-duty applications or in limited space conditions. 8. Pipe saddles: Pipe saddles are used to support pipes that need to be raised or protected from direct contact with a surface. They usually have a curved or U-shaped design that cradles the pipe. It is important to choose the appropriate stainless steel pipe hanger based on specific installation requirements, including pipe size, load capacity, movement, and environmental factors. Seeking advice from a knowledgeable supplier or engineer can assist in choosing the right hanger for the job.

- Q:Are stainless steel tubes and galvanized steel tubes the same?

- Galvanized steel pipe is common steel pipe, and then the surface coated with a layer of zinc coating, in order to prevent rust, as long as the surface layer is ground, it will rust.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel 304 sheet from China top manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords