Stainless Angle Steel Bar ASTM 316l with Customized Surface Treatment

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ASTM 316l Stainless Angle Steel Bar

Main Structure of Angle Steel Bar

1.Surface:Bright,Polished,Turn smooth(Peeled),Brush,Mill,Pickled

2.Length:3m, 6m,9m,12m

3.Use:These products are widely supplied to areas of machine-made industry,chemical industry,spin,shipping industry,architecture,food industry,household products etc

4 ISO9001:2008

Data Information of Angle Steel Bar

Standard | AISI, ASTM, BS, DIN, GB, JIS, etc |

Grade | Q195, Q215, Q235, Q345, SS400, A36, S235JR, ST37, etc |

Technical parameters:

1) Material: Q235B , Q 345B, SS400 ,SS540, S235JR ,ETC. | |||

| 2) Usage: structure construction and electronic tower building | |||

| 3) Weight tolarance: -4% TO -10% | |||

| 4) Size tolarance : | |||

| ANGLE STEEL SIstructural steel angleE TOLARANCE (MM) | |||

| SIstructural steel angleE cm | WIDTH b/mm | THICKNESS d/mm | LENGTH /m |

| 2-5.6 | +/-0.8 | +/-0.4 | 4-12 |

| 6.3-9 | +/-1.2 | +/-0.6 | 4-12 |

| 10-14 | +/-1.8 | +/-0.7 | 4-12 |

| 16-20 | +/-2.5 | +/-1.0 | 4-12 |

| 5) Payment terms: TT or LC | |||

| 6) Delivery date: within 30 days after receiving the LC or TT prepay | |||

| 7) Packing: Export package | |||

| 8) Inspection: accept third party inspection | |||

Specification of Angle Steel Bar

1.Square bar:Size: 4mm*4mm~100mm*100mm

2.Round Bar:Diameter: 3mm~800mm

3.Angel Bar:Size: 3mm*20mm*20mm~12mm*100mm*100mm

4.Flat bar:Thickness: 2mm~100mm,Width: 10mm~500mm,

5.Hexagonal :Size: 2mm~100mm

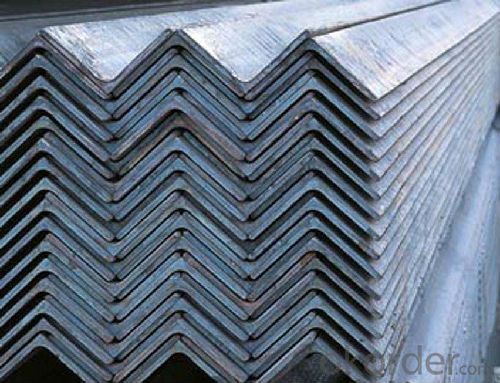

Picture

- Q:Can stainless steel angles be used in water treatment facilities?

- Yes, stainless steel angles can be used in water treatment facilities. Stainless steel is a highly corrosion-resistant material, which makes it ideal for use in environments that come into contact with water. Water treatment facilities often have a high moisture content and are exposed to various chemicals, making stainless steel angles a suitable choice for construction and structural components. The corrosion resistance of stainless steel ensures the longevity and durability of the angles, reducing the need for frequent maintenance and replacement. Additionally, stainless steel is hygienic, easy to clean, and resistant to bacterial growth, which is essential in water treatment facilities where maintaining water quality is of utmost importance. Therefore, stainless steel angles are a practical and reliable choice for use in water treatment facilities.

- Q:Can stainless steel angles be used in outdoor environments?

- Yes, stainless steel angles can be used in outdoor environments. Stainless steel is highly resistant to corrosion and rust, making it an ideal choice for outdoor applications where exposure to moisture, rain, and other environmental elements is common. This material's durability and strength make it suitable for various outdoor structures, such as handrails, fencing, and support brackets.

- Q:What are the different types of surface treatments for rounded corner stainless steel angles?

- Rounded corner stainless steel angles can be treated in various ways to achieve different surface finishes. Some commonly used options include: 1. Polishing: By utilizing an abrasive material, a smooth and shiny surface can be created on the stainless steel angle. This treatment effectively eliminates any flaws or scratches, resulting in a more visually pleasing outcome. 2. Brushing: Another popular treatment involves using a brush or abrasive pad to generate a textured finish on the stainless steel angle. Depending on the desired aesthetic, this can range from a fine satin finish to a more pronounced pattern. 3. Bead blasting: This method entails propelling small glass or ceramic beads at high velocity onto the surface of the stainless steel angle. Bead blasting achieves a consistent matte finish and also helps eradicate any surface contaminants. 4. Passivation: To enhance the corrosion resistance of the material, passivation is employed. This chemical treatment eliminates any free iron or other contaminants present on the surface of the stainless steel angle. It is particularly crucial for angles that will be exposed to harsh environments. 5. Powder coating: In this process, a dry powder is sprayed onto the stainless steel angle's surface and then cured in an oven. Powder coating yields a durable and visually appealing finish that can be customized in terms of color and texture. These examples demonstrate the range of surface treatments available for rounded corner stainless steel angles. The choice of treatment depends on factors such as desired appearance, functionality, and intended application of the angle.

- Q:What are the different surface textures available for stainless steel angles?

- Stainless steel angles, which are also referred to as stainless steel L-shaped bars, exhibit a range of surface textures based on specific requirements and desired aesthetics. Various surface textures commonly found in stainless steel angles include: 1. Hot rolled: The most prevalent surface texture observed in stainless steel angles, achieved by subjecting the steel to high temperatures and then rolling it into the desired shape and size. This process results in a rougher texture with a slightly scaled surface due to the heat treatment. 2. Cold drawn: This surface texture is obtained by subjecting the stainless steel angle to a series of processes such as drawing, annealing, and straightening. Cold drawn stainless steel angles possess a smoother and more polished appearance in comparison to hot rolled angles. 3. Sanded: Stainless steel angles can undergo sanding or brushing processes to attain a uniform and smooth surface texture. This is commonly done to enhance the angle's aesthetics and eliminate any imperfections or scratches. 4. Polished: Polished stainless steel angles possess a highly reflective and mirror-like surface texture. This is accomplished through mechanical polishing or buffing using abrasive materials or compounds. Polished stainless steel angles are frequently employed in decorative applications where a shiny and elegant finish is desired. 5. Bead blasted: Bead blasting involves subjecting the stainless steel angle to high-pressure shots of small glass beads or other abrasive materials. This process creates a uniform and matte texture with a slightly roughened surface. 6. Etched: Etching is a chemical process utilized to create decorative patterns or designs on the surface of stainless steel angles. This surface texture is achieved by applying an acid-resistant mask on the angle and subsequently applying acid to remove the unprotected areas, resulting in the desired pattern or design. These examples merely scratch the surface of the diverse range of surface textures available for stainless steel angles. The choice of texture depends on the intended application, desired appearance, and specific requirements such as corrosion resistance or ease of cleaning.

- Q:Can stainless steel angles be used in chemical plants?

- Yes, stainless steel angles can be used in chemical plants. Stainless steel is highly resistant to corrosion, making it suitable for environments with chemical exposure. Its strength and durability make it a reliable choice for structural components like angles in chemical plants.

- Q:How do you determine the yield strength of a stainless steel angle?

- The yield strength of a stainless steel angle can be determined through various methods, such as conducting a tensile test. In this test, a sample of the stainless steel angle is subjected to an increasing load until it reaches a point where it begins to permanently deform. This point is known as the yield point, and the load at which it occurs is the yield strength. By measuring the applied load and the corresponding deformation, the yield strength of the stainless steel angle can be determined accurately.

- Q:How do you calculate the shear stress of a slotted stainless steel angle?

- In order to determine the shear stress of a slotted stainless steel angle, various factors need to be taken into account. The first step is to ascertain the shear force exerted on the angle. This can be achieved by analyzing the load or force applied to the angle. Subsequently, the shear area of the slotted stainless steel angle must be calculated. The shear area refers to the section of the angle's cross-sectional area that will be subjected to the shear force. For a slotted angle, this can be determined by considering the width and thickness of the angle at the location of the slot. Once the shear force and shear area are known, the shear stress can be calculated using the following formula: Shear Stress = Shear Force / Shear Area It is crucial to employ consistent units for both the shear force and shear area to guarantee precise results. Additionally, any relevant safety factors or design codes that may impact the calculation should be taken into consideration.

- Q:What are stainless steel angles used for?

- Stainless steel angles are commonly used in various industries and applications due to their durability, strength, and corrosion resistance. These angles are primarily used for structural support and reinforcement purposes. They are often used in construction projects to provide stability and strength to buildings, bridges, and other structures. In addition to their structural applications, stainless steel angles are also widely used in the manufacturing and construction of machinery, equipment, and furniture. They can be found in industries such as automotive, aerospace, food processing, pharmaceuticals, and marine, among others. Stainless steel angles are particularly useful in situations where the material needs to withstand harsh environments or exposure to corrosive substances. Their corrosion resistance properties make them suitable for use in coastal areas, chemical plants, and other environments where moisture, chemicals, or saltwater may be present. Due to their versatility, stainless steel angles can be easily fabricated and welded to meet specific requirements. They can be cut, drilled, bent, and shaped to fit various applications, making them a preferred choice for many manufacturers and designers. Overall, stainless steel angles play a crucial role in providing structural integrity, support, and corrosion resistance to a wide range of projects and applications across different industries.

- Q:Can stainless steel angle be used in water distribution systems?

- Yes, stainless steel angle can be used in water distribution systems. Stainless steel is highly resistant to corrosion and can withstand the corrosive effects of water and various chemicals present in water distribution systems. It is also easy to clean and maintain, making it a suitable choice for use in these systems. Additionally, stainless steel angles provide strength and stability to the structure of the water distribution system, ensuring its durability and longevity.

- Q:What are the load-bearing capacities of stainless steel angle?

- Various factors, such as the dimensions and thickness of the stainless steel angle, the grade of stainless steel used, and the installation method, affect the load-bearing capacities of stainless steel angle. Stainless steel angle, also called stainless steel L brackets or stainless steel corner guards, is commonly used in construction, industrial, and architectural applications due to its high strength and resistance to corrosion. To determine the load-bearing capacity of stainless steel angle, one must calculate the maximum weight or force it can support without failing or deforming. This calculation involves considering factors like the yield strength of the stainless steel grade, the moment of inertia of the angle shape, and the support conditions. Different stainless steel grades have varying yield strengths, which is the maximum stress the material can handle before permanently deforming. Generally, higher-grade stainless steel angles have higher load-bearing capacities compared to lower-grade ones. The dimensions and thickness of the stainless steel angle are also significant in determining its load-bearing capacity. Wider and thicker angles generally have the ability to support greater loads compared to narrower and thinner ones. The installation method is also crucial in determining the load-bearing capacity of stainless steel angle. Properly secured angles, such as those bolted or welded to a structure, offer greater load-bearing capacities than angles supported by other means. To accurately determine the specific load-bearing capacity of a stainless steel angle for a specific application, it is advisable to consult relevant engineering standards, guidelines, or a structural engineer. They can provide precise calculations, considering any specific project requirements or constraints.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Angle Steel Bar ASTM 316l with Customized Surface Treatment

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords