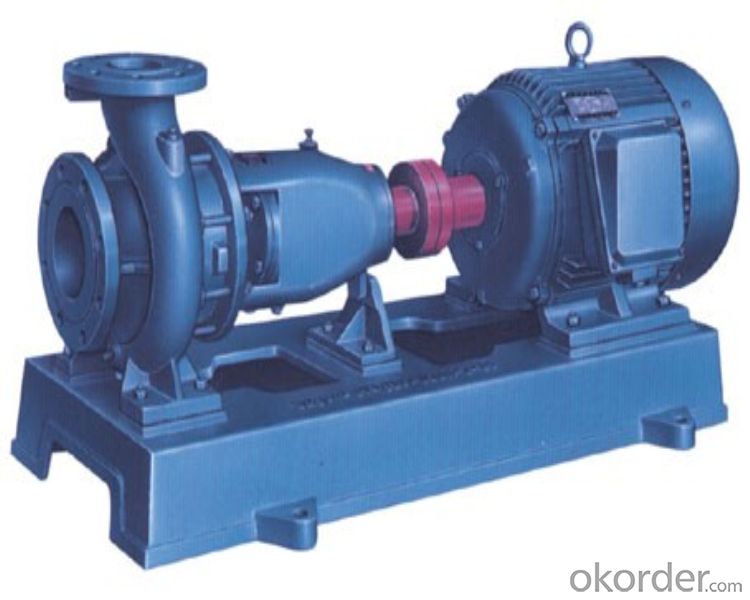

Stain Steel High Flow Rate Centrifugal Water Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Stain Steel High Flow Rate Centrifugal Water Pump

Company Introduce

My company has more than 40 years history, is the China general machinery pump industry association member units.

The company has organized product research and development team, experienced high, intermediate technical staff.Complete production and processing, inspection, testing (pump performance test platform), and other equipment, to ensure that product quality is stable and reliable.Over the department, provincial, municipal and industry product quality supervision and inspection (smoke), only one is qualified to go through.Timely quality perfect after-sales service in place, favored by the majority of new and old customers rely on and praise.

The company has successfully passed the national industrial products production license, ISO9001 quality system review replacement work.Relevant product standards (enterprise), metrology, standardization management system, etc., have been acceptance by the superior department in charge of the inspection.Related to product development, production management, sales and after-sales service, are performed according to the system management standard.

Product parameters of China Made Stain Steel Horizontal Centrifugal Pump

| Capacity: | 6.3~400m³/h |

| Head: | 5~125m |

| Speed: | 2900r/min and 1450r/min |

| Power of fitted motor: | 0.55~90kW |

| Inler diameter: | 50~200mm |

| The max working pressure: | 1.6MPa |

Application Range of Stain Steel High Flow Rate Centrifugal Water Pump

1.Suitable for environment protection, construction, fire fighting, chemical pharmacy, printing, dyeing, brewage, power plant, electroplate,

paper making, washing for mining and cooling for equipment.

2.Application as sprayer equipped with beam nozzle that turning water into little drop irrigation for farm, garden, etc.

3.It is suitable for clear water, sea water, acid or alkali chemical medium and slurry (viscosity≤100 centipoise, consistency of solid can not exceed 30% of total medium).

Stain Steel High Flow Rate Centrifugal Water Pump Features

1. Resistant to acid, alkali, wear and high temperature.

2. High mechanical strength, steady performance, good tightness.

3. Convenient operation and durable.

4. Be able to transport water that under the position it was installed. No need for filling liquid after the first time it was used.

Stain Steel High Flow Rate Centrifugal Water PumpSuperiority

High efficiency

Reasonable design

Reliable operation

Long in service time

Easy maintenance

Low running cost

Pictures show

Why choose us

High Quality

1.Exported to 58 Countries

2. More than 90% customers make payment before meeting us!

3. Reorder rate up to 80%

4. Never sell any renewed pumps

5. Focus on middle and high-end market,we never seize market by using inferior material

FAQ

1. How to get our quotation in time, pls answer following questions:

1)What liquid do you transfer?oil ,food or corrosive chemical liquid,with solid particle or not and so on

2) What's the flow or capcity (m3/h, L/m)?

3) What's the discharge head (m, feet, Mpa, bar )

If you do not have any request, we will do as our normal standard.

4) Contact us by under business card information

2.OEM: Ok

3. MOQ: 1set

4. Package: Standard export wooden case(also according to your requirements)

5. Shipping ways: By sea, By air, By express

6. Lead time: 3-15days

7. Warranty Period: One year, except spare parts

Trading market

After-sales service

Transportation

Related products

|

|

Fire Pump Cast Steel High Speed China Made | Cast Steel Centrifugal Pump High Pressure |

| http://www.okorder.com/p/fire-pump-cast-steel-high-speed-china-made_976663.html | http://www.okorder.com/p/cast-steel-centrifugal-pump-high-pressure_975173.html |

- Q:I bought a salt water filter system for my inflatable pool(14' X 40deep) and filled it up with 80 pounds of salt as the directions call for. Unfortunately Intex did not design the pump correctly and it leaks.There is supposed to be some copper ion exchange with the water as it goes through the system. I returned the salt water system. Since salt is a natural bacterial fighter by itself, can I just add salt once in a while and keep the water salty and use the filter pump that came with the pool? You never see lakewater(which is a little salty) with algae in it unless it is stagnant. With a filter pump this would not happen as the water is being filtered frequently.

- I don't think you or others really understand a salt water chlorination unit. The salt is added to the pool water through water circulation of the pool water the ION unit water passes past these two electrodes which in turn give off a chlorine gas which becomes the chlorine requirements for the pool On the ioniser is a dial that is set to a required setting to do with the volume of certain sized swimming pools. Even though one has this unit connected to their pool, they still have to add chlorine to their pool of the chlorine level isn't enough. This can be done in various methods, via a floating skimmer or have pellets put in hair lint pot or scattered over the pool surface, once dissolved in a bucket of warm water. Just by leaving the salt in the water as you suggest won't really do much other than help keep the water salty! This is my opinion I'll not get into a wage or wars over who is right who is wrong! Your trying to get others on your side, because you made the wrong choice purchased a salty pool chlorinator pump your dis- satisfied with your choice I am not going to agree or disagree with your statement other that to say your putting your families health at risk being a skin flint! So you think your doing the right thing, by putting your families health at risk for the sake of a few lousy dollars. Do it properly have a professional to come connect it all up for youin a proper manner!! Surely your families health means a lot more to you than risking a few lousy bucks on the proper unit! Cheers!!

- Q:Is there a way to test and see if it is the water pump that causes the car heater to blow hot air one time and then, next time it blows cold air? We flushed the heater core and did other tests, so we do not believe it is the heater core. We left the radiator cap off and ran the car (ford thunderbird..'94) for 20 minutes and watched the antifreeze level come up, but doesn't go down, not circulating. We cannot afford to go to another garage. None of them seem to know what to do anywyas and we keep paying people to fix the heater and it is not fixed. We have put two new thremostats in car, too, figuring that maybe the first one may have been faulty, but should we try that again?

- On many cars you cannot see the coolant circulating especially at idle. Just because you do not have heat does not mean the water pump, and if your car is not overheating it is probably - I say probably - doing its job. So stop putting thermostats on, probably assume the water pump is okay. So, put a thermometer into the radiator to see how hot the coolant is getting - should be ~180 degrees or so. Hmmmm - Does this car have an electronic climate control system? Perhaps that is the reason you have an intermittant problem. Assuming manual climate control - It could be a vacuum leak to one of the manual vents that is allowing cool air to mix with the hot. Or, maybe the slider from hot to cold is not working. What troubles me is the intermittant problem here. So, I will go out on a limb and say it could possibly be a bad head gasket for reasons I will not get into here. In any case, Good Luck!

- Q:In case our electric goes out we would like to be able to run the water pump (for the well) via solar panel. Can you give me instructions, pitfalls, recommendations, links etc to help me get started?The more solar info i can get the better!thanks 10 points on offer!Our sunlight is unobstructed

- First okorder /

- Q:I have a 1969 Chrysler with a new 3 core radiator. It still has the stock water pump and I am wondering if a high volume pump would make it run cooler at higher speeds. It runs hotter when you get off the freeway. I have flushed the system and installed a new thermostat. I also replaced the fan clutch. I am at a loss of why it still runs warmer than the 180* thermostat.

- High Volume Water Pump

- Q:All of a sudden I have no water coming to the house/anywhere from the pump/well outside. It's a newer well, good water quantity (Florida...no dry up problems), no sand in water. I'm new to this house and don't know much about the pump stuff. Is there something I should look at or switch on/off. The breaker is ok. Help, I need a shower! :) Oh, there were about 15 ants around some box, but it didn't look connected to the pump...it's a box to the pool filter thing.

- This Site Might Help You. RE: No Water in house/well/pump? All of a sudden I have no water coming to the house/anywhere from the pump/well outside. It's a newer well, good water quantity (Florida...no dry up problems), no sand in water. I'm new to this house and don't know much about the pump stuff. Is there something I should look at or switch...

- Q:gould water pump model Jo5n

- Any pump that works deep, will work shallow. Just make sure it doesn't pump enough water out of the well so it is not in water while it pumps. It depends on being in water for its cooling. Jet pumps, submersible pumps will work no problem. With the jet pump the motor is not in the water. So it would work in shallower water. The difference between a deep well pump and a shallow one is the shallow pump uses a vacuum to draw the water up out of the well. Where a deep well pump pushes the water up from the well.

- Q:Where is the water pump located on a 1998 dodge dakota sport?

- The fan is mounted on the front of the water pump. Find the fan and right behind it is the water pump. Should be a big black circle looking thing. I know the water pump is not round. I didn't mean it was round. The thing the fan mounts to is round, which is part of the water pump. Yeah I noticed that too bluto: kinda funny

- Q:Level 200 meters distance, elevation 30 meters, how much lift water pump?

- According to the horizontal distance of 10 meters is 1 meters lift, 200 meters is 20 meters and 5 meters height difference of 30 Mega elbow, pump head floating down 10%, should be about 60 meters.

- Q:So my daughter's car is an 02 Accord manual with about 127k miles. It's making a squeaky noise which apparently is the belts. The dealer says they're too tight, but are in okay condition. They want to change the water pump and adjust the belts for $750. This seems a bit steep to me. Does the water pump need to be changed if it's working properly? How much should it cost to adjust the belts? I'm thinking she should find a more reasonable shop. What are your thoughts?

- The water pump is driven by the timing belt. I do the water pump and timing belt with the pulleys and tensioner for around $600. If the drive belts are making noise try dusting some talcum or body powder on them. Don't use belt dressings, they never work.The timing belt should be replace around 90,000 miles so if that hasn't been done you should have it replaced or you will bend all the valves when the timing belt jumps or breaks. That's a 14 year old vehicle and the timing belt needs attention.

- Q:I have a 2000 A4 1.8 T with 91 k miles on it. I went to the dealer for my oil service. I told them that I hear a quot;clinkingnoise when I start the car and that it goes away after the car runs for 5 minutes. I told them to check this also. They diagnosed and said that the water pump has gone bad and needs to be replaced. Since it was close to 105 K miles, I might as well change the timing belt. Total charges for both is 1250. And they also see that Cam Seals starting to leak oil. Since I was doing the timing belt, I might as well change them too. Additional cost to do them is 950. So the total for all three comes down to 2200. I bought the car at 90 K and checked it at Firestone and they said it was cool. They noticed an oil leak but said it was not anything major that needs to be taken care of right away. Do you think the dealer is taking me for a ride here? I just drove 500 miles and would things go this bad all of a sudden? Or should I make the replacements? Please advise.

- I used to work for a dealer, they price by the book, even if they are already in there.... so if say you want to replace your alternator and your belts, they look up what labor is on the alternator, and then look up what labor on the belts is and add them together, even though youd have to pull the belts to change the alternator anyways. So basically you get charged for labor twice under this system. A different shop should be able to do this cheaper. If your water pump is out you should be overheating...... If youre doing the timing belt though, you probably want to look into those cam seals, if they leak on your timing belt they will weaken the belt and maybe make it break, which is really bad if you have an interferance engine (meaning if the pistons are up and the valves are down they will hit, usually breaking/bending the valves). The dealer should know if its an interferance engine or not, or you could do a quick internet search. If the belt has never been replaced i would definately recommend doing it though. Whatever you end up doing though, i would get a second opinion from a non dealer. At toyota they would charge more for lexus parts than toyota parts, even though it was the same part with a different part number... you may be in the same sort of boat with the audi.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stain Steel High Flow Rate Centrifugal Water Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords