Stable Quality Anti-noise Rubber Seal Strip

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stable Quality Anti-noise Rubber Seal Strip:

1. Brief Description of Stable Quality Anti-noise Rubber Seal Strip

Rubber seal could stop air, water and dust enter the machine system, which could protect the machine boat or automotive parts to be healthy and working well.

2. Main Features of Stable Quality Anti-noise Rubber Seal Strip

1.good anti-friction,anti-aging, anti-corrosion effect

2. Weather proof, vandal proof, and can be shaped, molded, painted and screen printed.

3. Non-corrosive, non-toxic and chemical resistant .

4. Soft with high impact strength .

5. Non-warping and stain proof.

6. Easy to clean and maintain .

7. Easy to operate, including glue, nail, cut or shape.

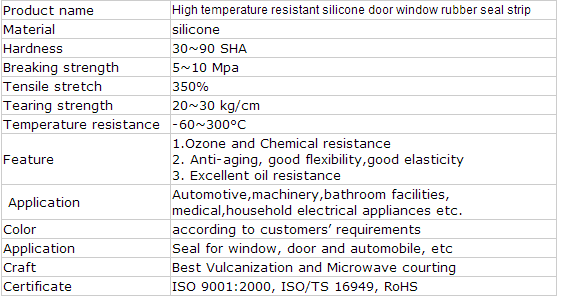

3. Main Specification of Stable Quality Anti-noise Rubber Seal Strip

4. Pictures of Stable Quality Anti-noise Rubber Seal Strip

5. FAQ

(1)Q: Are you a factory or trading company

A: We are tading company with import and export lisense and have our own factory.

(2)Q: Do you offer samples of anti-noise rubber seal strip ?

A: We are glad to offer you free samples. New clients are expected to pay for the delivery cost,this charge will be deducted from the payment for formal order.

(3)Q: How about the lead time?

A: Within10-20 days after getting the prepayment.

(4)Q: How can we pay?

A: For small sample shipping cost, you can pay either by paypal or by T/T. And by T/T at sight for large amount of the order.

(5)Q: Can you do CO, Form E, Form F, Form A etc?

A: Yes, we can do them for you.

- Q:What is the definition of mixed rubber?

- Physical property:Its properties vary depending on the monomer, and the properties of a few varieties are similar to those of natural rubber. Some synthetic rubber is superior to natural rubber in good temperature resistance, wear resistance, ageing resistance, corrosion resistance, oil resistance and so on.Under the condition of use, it is highly elastic and has a certain modulus.

- Q:How to clean rubber products?

- Rubber is elastic hot melt thermosetting body, plastic is hot cold setting. Rubber due to different types of sulfide species, its molding and curing temperature range is also a considerable gap, and even can be affected by climate change, indoor temperature and humidity affected. Therefore, the production conditions of rubber products need to be adjusted at any time. If not, the quality of the products may be different.

- Q:Is vulcanized sole good or rubber sole is good?

- Vulcanized soles are vulcanized rubber, after vulcanization, this step of rubber products are not easy to aging, cracking, good elasticity, heat resistance, and now the rubber products are basically this kind of rubber, also known as mature rubber, collectively referred to as rubber or rubber

- Q:There is a crack in rubber products

- The additive time temperature and pressure of semi-finished shapes semi-finished semi-finished products placed as far as possible when placed speed gap semi-finished size can be more appropriate to put five percent to ten percent semi finished mixing can put some help curing

- Q:Are there formaldehyde in rubber products, too?

- Outstanding performance: headache, dizziness, fatigue, nausea, vomiting, chest tightness, eye pain, sore throat, poor appetite, palpitations, insomnia, weight loss, memory loss and autonomic nerve disorder; long-term inhalation of pregnant women may result in fetal deformity, even death, men's long-term inhalation can cause male sperm deformity and death.

- Q:How can rubber be made into rubber when it is made?

- Just cut off the rubber is not available, belongs to the first rubber, according to the products and the use of working conditions to set the formula, made of mixed rubber, vulcanized on the vulcanization machine with mold has been good, curing after trimming, testing, packaging. The required rubber products will be ready.The process flow of the production process is:Raw material preparation, plasticization, blending, molding, vulcanizing, cleaning and testing

- Q:Is polyurethane and polyurethane rubber one thing?

- Polyurethane, plastics and rubber are made of polyurethane resin polymer composite material, the specific material and production process is different, resulting in polyurethane polymer chain molecular weight and performance of different.Polyurethane can also be used in coatings, adhesives and other fields, the use is very extensive.

- Q:How to improve the aging resistance of rubber?

- The shorter the light wave, the greater the energy, the greater the damage to the rubber. Ultraviolet not only directly caused the breakage and crosslinking rubber, rubber surface is also resillage guttacontent especially high rubber is more obvious this is the light splitting outer rubber particles (black rubber particles and colored rubber particles).

- Q:Is silicone good or rubber good?

- Rubber is divided into natural rubber and synthetic rubber, natural rubber structure is isoprene polymer, synthetic rubber such as polybutadiene rubber, chloroprene rubber, styrene butadiene rubber. When rubber is deformed by the external force, the crosslinked rubber has the ability to recover quickly, and has good physical and mechanical properties and chemical stability.Silicone rubber is mainly composed of high molecular weight linear polysiloxane. The Si-O-Si key is the basic bond formed, mainly methyl silicon atoms connected, introduced a very small amount of unsaturated groups in side chain, intermolecular interactions, molecular spiral structure, methyl arrangement and can freely rotate outward, thus vulcanized silicone rubber has excellent resistance to high and low temperature (-100~315 DEG C). Weather, water repellent, electrical insulation, physiological inertia and other characteristics, are widely used in military, medical, industrial and agricultural production and people's daily life. Most importantly, there is no toxicity, as usual in pacifiers and breast implants.

- Q:Rubber products are not allowed to touch oil products, but why can rubber gloves be contacted daily? What's the point?

- Contact every day is not every day inside the bubble, the contact time is short, the impact on rubber is very small.Raw rubber rubber products are: natural rubber, isoprene rubber, nitrile rubber, EPDM rubber, polybutadiene rubber, styrene butadiene rubber, polyurethane rubber, chloroprene rubber, silica gel etc.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stable Quality Anti-noise Rubber Seal Strip

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords