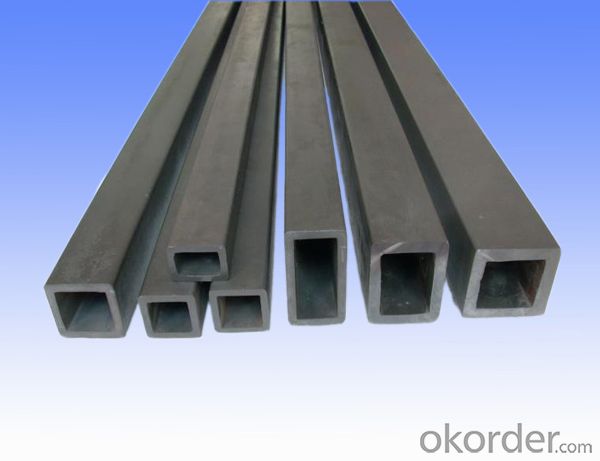

SSIC Silicon carbide tube

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 500 pc/month

- Option:

- order

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Tailor-made for customers all kinds of pumps with my company, kettle, bearing no pressure sintering silicon carbide mechanical seal, and all kinds of resistance corrosion pump parts and the accessories. Our company pressureless sintered silicon carbide products a reaction bonded silicon carbide products, can easily adapt to the harsh working conditions, in strong corrosive, strong wear, high temperature, high pressure, high strength harsh harsh under complex conditions is more outstanding. At the same time, our company to provide customers with nozzles, armored body armor plate and other special-shaped pieces of custom-made service.

Compared with the reaction sintered silicon carbide product (SSIC), the production process of the sintered silicon carbide product (RBSIC) is complex and the production investment is high. In addition, whether it is in the resistance to corrosion and abrasion, compressive and flexural fracture resistance of or high pressure, high temperature and other properties are more excellent, this is pressureless sintering silicon carbide products will in the near future completely replace reaction bonded silicon carbide products is one of the important reasons. The main varieties of the pressureless sintering silicon carbide products with all kinds of mechanical seal with sealing ring and moving ring and static ring, corrosion resistant pump, magnetic pump, shield pump components. At the same time, the production special-shaped pieces of nozzle, wire drawing die, armor plate. According to the drawings, we will provide customers with satisfactory products and customer satisfaction. Let customer satisfaction is one of the purposes of our company has been pursued, but also one of the objectives pursued by all the staff of our company.

Features: high temperature resistance, wear resistance, corrosion resistance, oxidation resistance, hardness, heat conduction

Main products: mechanical seals, pump parts, nozzles, bullet proof plate

Mechanical seals: high hardness, high wear resistance, good self - Lubrication and high heat conductivity, so the service life of mechanical seal is greatly improved.

Pump: resistance to corrosion and wear characteristic of the pressureless sintering silicon carbide become magnetic pump sliding bearing, resistant corrosion pump sleeve, shielding pump assembly, etc. various kinds of pump of choice

Nozzle: wear resistant, high temperature resistance, high hardness characteristics of the normal pressure sintering silicon carbide nozzle to become a perfect alternative to carbide nozzle

Armor: light weight, high hardness, good ballistic performance, pressureless sintering of SiC for your life and property security escort

medium | content | Causticity | |||||||

Atmospheric SIC | The reaction SIC WC | WC | AL2O3 | ZrO2 | Si3N4 | stainless steel | steel | ||

HNO3 nitric acid | 50% | A | A | C | A | A | C | C | C |

Hydrochloric acid HCI | 35% | A | A | C | A | A | C | C | A |

Sulfuric acid H2SO4 | 98% | A | A | C | A | A | C | C | A |

Hydrofluoric acid HFF | 40% | A | C | C | C | C | C | C | C |

Phosphoric acid H5PO4 215OC | 85% | C | C | C | C | C | C | C | C |

HNO3+HF | 20%+5% | A | C | C | C | C | C | C | C |

Sodium chlorate NaCIO | 10% | A | B | C | A | A | A | C | A |

Sodium hydroxide NaOHH | 50% | A | C | A | B | A | B | A | A |

Potassium hydroxide KOH | A | C | A | B | A | B | A | A | |

Acetic acid CH3COOHH | 80% | A | A | C | A | A | C | C | C |

Sodium sulfate + Na2CO3 + H2SO4 925OC

| A | A | C | A | A | C | C | B | |

Silica solution SIO2

| B | C | C | C | C | C | |||

Assessment Method: the specimen prior polishing, immersed in the test liquid (70OC) for 100 hours, the weight was measured and observed microstructure, weight reduction is calculated by the degree of corrosion was observed microstructure for corrosion to comprehensive judgments. | |||||||||

A level (corrosion): corrosion rate ≤0.125mm / ingredients in a small amount of corrosion observed slice | |||||||||

Level B (somewhat resistant): corrosion rate = 0.125-1.0mm / or annual corrosion rate ≤0.125mm / observe a large number of corrosion | |||||||||

Class C (resistant to corrosion): corrosion rate ≥1.0mm / or the main ingredient of Corrosion

Silicon carbide performance indicators

Index Name

| Atmospheric SiC | Reaction Bonded Silicon Carbide |

Purity (%) of silicon carbide | > 97 | >90 |

Density (g / cm) | 3.06-3.15 | >3.05 |

Particle size (um) | 0.5-0.7 | 8-20 |

Hardness (HRA) | ≥90 | ≥90 |

Flexural Strength (MPa) | 400-580 | 350-450 |

Compressive strength (MPa) | 3900 | >2500 |

Fracture Strength (MPa) | 3.05-4.6 | 4.3 |

Elastic Modulus (GPa) | 380-410 | 420 |

Thermal conductivity | 102.6 | 35-110 |

Coefficient of thermal expansion (1 / ℃) | 4.02×10 | 4.3×10 |

Poisson's ratio | 0.14 | 0.15 |

- Q:How should the piston rings for piston wear be chosen? What is the national standard?

- Cylinder piston due to long-term reciprocating motion, reciprocating piston seals should be used to require wear-resistant, oil corrosion resistance, hardness is best at about 85 degrees.The choice of sealing ring material is of great importance to its sealing performance and service life. The performance of the material directly affects the performance of the sealing ring.

- Q:What's the function of the sealing ring?

- Composition of mechanical sealMechanical seals are mainly composed of the following four components. 1. Main seals: moving ring and stationary ring. 2. Auxiliary sealing parts: sealing ring. 3, pressing parts: spring, push ring. 4, transmission parts: play skip and key or fixed screw.

- Q:All the seals in the car engines, especially those sealed in the cylinders.

- Valve oil seal, piston ring, front and rear crankshaft oil seal.

- Q:What are the basic parameters of the seal on the diagram?

- Application: special oil cylinder, pump / valve, machine tool, robot hand, servo mechanism

- Q:What is the optimum amount of compression for the seal? Is the amount of compression related to the material of the sealing ring? What is the relationship between the hardness of the sealing ring and the hardness of the sealing ring?

- Ding Qing rubber resistant mineral oil, silicone oil, animal oil, esters, HFA, HFB, HFC, air and water, water resistance increased with the increase of propylene, but low temperature and permeability decreased. Not suitable for phosphate system hydraulic oil and polar additives gear oil, suitable for temperature -30~100, generally used for O ring, oil seal and so on

- Q:Why can't polyurethane seal be used as hydraulic oil with water glycol?

- Water glycol lubrication performance is poor, high pressure, sealing components and cylinder block of friction, fever is very serious, so require sealing material to withstand high temperature, usually use fluorine rubber material. Polyurethane is not high temperature, more than 80 degrees when the deformation under pressure, the intensity is low, simply can not use.

- Q:What are the seals commonly used in the industry?

- In recent years, with the development of economy, the development of sealing industry is very fast. But unlike other industries, the development of the sealing industry is rapid, but the sealing enterprises are changing slowly. For example, at the end of 70s and early 80s, there are several manufacturers only in Jiangsu, Zhejiang and Shandong, and both coastal and inland, and the South and the north, everywhere seal factory, the entire industry has been sealed by the previous few, the development of 300, the growth rate can be said to be very fast. But in terms of individual enterprises, many enterprises did not change, the scale of production roundabout, or even reverse, the power of science and technology not only did not increase greatly, but some in the weakened, many manufacturers still hold "four old" do not put, that old products, old technology, old equipment, old size. Of course, there are some enterprises, imitation, imitation of some products stronger ability, but in the industry as a whole, independent development of new products capacity of enterprises is not much.In terms of products, the vast majority of manufacturers are still some winding gasket, packing ring, packing and high strength gaskets and other old products. Slightly new PTFE products, in technology and quality greatly behind foreign countries, such as PTFE packing, expansion PTFE tape. Looking around, new products are scarce.

- Q:Mechanical, I often need to use seals, when used, suddenly do not know the specifications, size, which guy knows what manuals can be found?

- It also introduces how to choose the sealing material and the sealing type reasonably according to the working conditions, and the design of the sealing structure is carried out. In addition, all kinds of seals conforming to the national standard are also provided for readers to choose from

- Q:What are the seals that are resistant to 500 degrees of high temperature?Airtight chamber gas temperature up to 500 degrees, what are the appropriate seals available? Thank you

- Airtight container seals are static seal, you can use the "flexible graphite" material made of seals, capable of more than 1000 degrees high temperature. (dynamic seal does not apply).

- Q:Classification of sealing strip by use

- Seals can be divided into two categories: static seal and dynamic seal.Static sealStatic seals are mainly gasket seal, sealant sealing and direct contact sealing three categories. According to the work pressure, static seal can be divided into medium and low pressure static seal and high pressure static seal. Low and medium pressure static seals are usually made of soft and wide width gasket. High pressure and static seals are made of hard material and metal gaskets with narrow width.Dynamic sealDynamic seals can be divided into rotary seal and reciprocating seal two basic types.OtherAccording to the seal of the relative movement of the parts is divided into sealing contact, contact and non-contact seal; according to the seal and the contact position can be divided into circumferential seal and the seal, the seal is also called mechanical seal. The centrifugal seal and spiral seal in the dynamic seal are sealed by the power of the medium when the machine is running, so it is sometimes called the power seal.According to the type of sealing structure, sealing mechanism, seal shape and material, the seal can be classified according to table 29.2-1.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

SSIC Silicon carbide tube

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 500 pc/month

- Option:

- order

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products