SSAW Welded Steel Pipes API SEPC 5L API SPEC 5CT ASTM A53

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- based on order m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Specification of SSAW Welded Steel Pipes API SPEC 5CT ASTM A53 ASTM A53

1)Application: It is widely applied to line pipe in oil and sewage transportation , and it is used in Low pressure liquid and gassy transportation and it is also good Structure pipe in building and bridge field.

2)Standard: API SPEC 5L, API SPEC 5CT, ASTM A53, GB/T9700.1

3)Steel Grade: API SPEC 5L: B, X42, X46, X52, X56, X60, X65; API SPEC 5CT: J55, K55, N80, L80-1;ASTM A53: A, B, C; GB/T9700.1:L242、L290、L320、L360、L390、L415、L450

2. Sizes of SSAW Welded Steel Pipes API SPEC 5CT ASTM A53 ASTM A53

OD | WT | ||||||||

Noninal Pipe size Inches | MM | 10 | 20 | 30 | STD | 40 | 60 | XS | 80 |

12 | 323.90 |

| 6.35 | 8.38 | 9.53 | 10.31 | 14.27 | 12.70 | 17.48 |

14 | 355.60 | 6.35 | 7.92 | 9.53 | 9.53 | 11.13 | 15.09 | 12.70 | 19.05 |

16 | 406.40 | 6.35 | 7.92 | 9.53 | 9.53 | 12.7 | 16.66 | 12.70 | 21.44 |

18 | 457.00 | 6.35 | 7.92 | 11.13 | 9.53 | 14.27 | 19.05 | 12.70 | 23.88 |

20 | 508.00 | 6.35 | 9.53 | 12.7 | 9.53 | 15.09 | 20.62 | 12.70 | 26.19 |

22 | 559.00 | 6.35 | 9.53 | 12.7 | 9.53 |

| 22.23 | 12.70 | 28.58 |

24 | 610.00 | 6.35 | 9.53 | 14.27 | 9.53 | 17.48 | 24.61 | 12.70 | 30.96 |

26 | 660.00 | 7.92 | 12.70 |

| 9.53 |

|

| 12.70 |

|

28 | 711.00 | 7.92 | 12.70 | 15.88 | 9.53 |

|

| 12.70 |

|

30 | 762.00 | 7.92 | 12.70 | 15.88 | 9.53 |

|

| 12.70 |

|

32 | 813.00 | 7.92 | 12.70 | 15.88 | 9.53 | 17.48 |

| 12.70 |

|

34 | 864.00 | 7.92 | 12.70 | 15.88 | 9.53 | 17.48 |

| 12.70 |

|

36 | 914.00 | 7.92 | 12.70 | 15.88 | 9.53 | 19.05 |

| 12.70 |

|

38 | 965.00 |

|

|

| 9.53 |

|

| 12.70 |

|

40 | 1016.00 |

|

|

| 9.53 |

|

| 12.70 |

|

42 | 1067.00 |

|

|

| 9.53 |

|

| 12.70 |

|

44 | 1118.00 |

|

|

| 9.53 |

|

| 12.70 |

|

46 | 1168.00 |

|

|

| 9.53 |

|

| 12.70 |

|

48 | 1219.00 |

|

|

| 9.53 |

|

| 12.70 |

|

*Remarks: Besides referred sizes, we also can arrange production based on requirement of costumers.

3. Packing&Delivery

Packing Detail: Bundles with anti-rust painting and with plastic cap

Delivery Time: Within 20-30 days upon receving prepayment or L/C

4. Data Sheet

Standard: API SPEC 5L

Mechanical Properties

Standard | Grade | (MPa) | (MPa) | ||

Yield strength | Tensile Strength | ||||

API SPEC 5L | PSL1 | ||||

B | ≥241 | ≥414 | |||

×42 | ≥290 | ≥414 | |||

×46 | ≥317 | ≥434 | |||

×52 | ≥359 | ≥455 | |||

×56 | ≥386 | ≥490 | |||

×60 | ≥414 | ≥517 | |||

×65 | ≥448 | ≥531 | |||

×70 | ≥483 | ≥565 | |||

PSL2 | |||||

Min | Max | Min | Max | ||

B | 241 | 448 | 441 | 758 | |

×42 | 290 | 496 | 414 | 758 | |

×46 | 317 | 524 | 434 | 758 | |

×52 | 359 | 531 | 455 | 758 | |

×56 | 386 | 544 | 490 | 758 | |

×60 | 414 | 565 |

517 |

758 | |

×65 |

448 |

600 |

531 |

758 | |

×70 |

483 |

621 |

565 | 758 | |

Chemical Composition(%)

Standard |

Grade | C | Mn | P | S | TI | CEV |

Max | Max | Max | Max | Max | Max | ||

API SPEC 5L | PSL1 | ||||||

B | 0.26 | 1.2 | 0.030 | 0.030 | 0.04 |

- | |

×42 | 0.26 | 1.3 | 0.030 | 0.030 | 0.04 | ||

×46,×52,×56,X60 | 0.26 | 1.4 | 0.030 | 0.030 | 0.04 | ||

X65 | 0.26 | 1.45 | 0.030 | 0.030 | 0.06 | ||

X70 | 0.26 | 1.65 | 0.030 | 0.030 | 0.06 | ||

PSL2 | |||||||

B | 0.22 | 1.20 | 0.025 | 0.015 | 0.04 |

0.43 | |

×42 | 0.22 | 1.30 | 0.025 | 0.015 | 0.04 | ||

×46,×52,×56, X60 | 0.22 | 1.40 | 0.025 | 0.015 | 0.04 | ||

X65 | 0.22 | 1.45 | 0.025 | 0.015 | 0.06 | ||

X70 | 0.22 | 1.65 | 0.025 | 0.015 | 0.06 | ||

Standard: GB/9711.1

Mechanical Properties

Standard | Grade | (MPa) | (MPa) | Min(%) |

Yield strength | Tensile Strength | Elongation | ||

GB/T9711.1 | L245 | ≥245 | ≥415 | 21 |

L290 | ≥290 | ≥415 | 21 | |

L320 | ≥320 | ≥435 | 20 | |

L360 | ≥360 | ≥460 | 19 | |

L390 | ≥390 | ≥490 | 18 | |

L415 | ≥415 | ≥520 | 17 | |

L450 | ≥450 | ≥535 | 17 | |

L485 | ≥485 | ≥570 | 17 |

Chemical Composition(%)

Standard | Grade | C | Mn | P | S |

Max | Max | Max | Max | ||

GB/T9711.1 | L245 | 0.26 | 0.15 | 0.030 | 0.030 |

L290 | 0.28 | 1.25 | 0.030 | 0.030 | |

L320, L360 | 0.30 | 1.25 | 0.030 | 0.030 | |

L390, L415 | 0.26 | 1.35 | 0.030 | 0.030 | |

L450 | 0.26 | 1.40 | 0.030 | 0.030 | |

L485 | 0.23 | 1.60 | 0.025 | 0.030 |

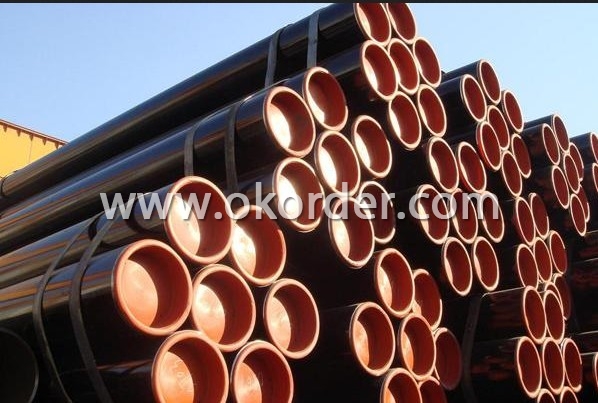

5. Products Showroom

- Q:How do you calculate the pipe thermal expansion coefficient for steel pipes?

- In order to calculate the pipe thermal expansion coefficient for steel pipes, it is necessary to take into account both the linear expansion coefficient of the material and the temperature change. The typical linear expansion coefficient for steel is approximately 12 x 10^-6 per degree Celsius. To begin with, establish the initial length of the pipe, which is represented by L0. Then, measure the temperature change, indicated as ΔT. Proceed by multiplying the initial length of the pipe by the linear expansion coefficient and the temperature change: ΔL = L0 * α * ΔT. The resulting value, ΔL, signifies the alteration in length of the steel pipe caused by thermal expansion.

- Q:How are steel pipes sized and classified?

- Steel pipes are sized and classified primarily based on their outer diameter (OD) and wall thickness. The sizing of steel pipes is standardized to ensure compatibility and ease of use in various applications. The most common method of sizing steel pipes is by nominal pipe size (NPS), which is a North American standard that refers to a pipe's OD. NPS sizes range from 1/8 inch to 36 inches, with each size corresponding to a specific OD. For example, a 1/2-inch NPS pipe has an OD of 0.84 inches, while a 12-inch NPS pipe has an OD of 12.75 inches. It is important to note that the OD of a pipe may not necessarily match its actual measurement, as it is based on historical pipe dimensions. Additionally, steel pipes are classified into different schedules, which indicate the wall thickness of the pipe. The most common schedules are SCH 5, SCH 10, SCH 40, SCH 80, and SCH 160, with higher numbers representing thicker walls. These schedules are standardized and help in selecting the appropriate pipe for a given application. Furthermore, steel pipes may be further classified based on their end connections. The most common types include threaded, plain-end, and socket-weld connections. Threaded pipes have screw threads on both ends, allowing for easy assembly and disassembly. Plain-end pipes have no threads and are usually joined using welding techniques. Socket-weld pipes have a socket-like end that allows for welding with a corresponding fitting. In summary, steel pipes are sized and classified based on their outer diameter, wall thickness, and end connections. The nominal pipe size (NPS) indicates the outer diameter, while the schedule number represents the wall thickness. Understanding the sizing and classification of steel pipes is crucial in selecting the appropriate pipe for specific applications in industries such as construction, oil and gas, plumbing, and manufacturing.

- Q:What are the different methods of inspecting steel pipes?

- There are several methods of inspecting steel pipes, including visual inspection, non-destructive testing (such as ultrasonic testing, magnetic particle testing, and dye penetrant testing), radiographic testing, and eddy current testing. These methods help identify any defects, such as cracks, corrosion, or wall thickness variations, ensuring the quality and integrity of the steel pipes.

- Q:What are the different types of steel pipe connections for steam pipelines?

- There are several types of steel pipe connections commonly used for steam pipelines. These include threaded connections, flanged connections, welded connections, and grooved connections. Each type has its own advantages and is chosen based on factors such as the pipe size, pressure, and temperature requirements, as well as the ease of installation and maintenance.

- Q:How are steel pipes used in the chemical industry?

- Steel pipes are commonly used in the chemical industry for various applications including the transportation of corrosive chemicals, as well as for transferring fluids and gases at high temperatures and pressures. These pipes are durable, resistant to corrosion, and can withstand harsh working conditions, making them ideal for handling chemicals in industrial settings.

- Q:Can steel pipes be used for gas transmission pipelines?

- Yes, steel pipes can be used for gas transmission pipelines. Steel is a commonly used material for gas pipelines due to its strength, durability, and ability to withstand high pressure and extreme temperatures. It is resistant to corrosion and can effectively transport natural gas or other gases over long distances. Additionally, steel pipes can be welded together to create a continuous and leak-proof pipeline, ensuring the safe and efficient transmission of gas.

- Q:What are the different types of steel pipe fittings?

- There are various types of steel pipe fittings, including elbows, tees, reducers, couplings, unions, plugs, caps, and flanges.

- Q:Can steel pipes be used for structural applications?

- Yes, steel pipes can be used for structural applications.

- Q:How do steel pipes handle pressure surges?

- Steel pipes are designed to handle pressure surges effectively due to their inherent strength and durability. The high tensile strength of steel allows it to withstand significant pressure fluctuations without deforming or bursting. Additionally, the seamless construction of steel pipes ensures a smooth and continuous flow, minimizing the impact of pressure surges. Furthermore, steel pipes can be reinforced with additional support structures, such as braces or anchors, to further enhance their ability to handle pressure surges.

- Q:How are steel pipes tested for pressure and leakage?

- Steel pipes are tested for pressure and leakage using a variety of methods to ensure their safety and reliability. One common method is hydrostatic testing, where the pipe is filled with water and subjected to a specific pressure for a specified duration. This test helps identify any weaknesses or leaks in the pipe by observing if there is any pressure drop or visible water leakage. The pressure is carefully measured and monitored during the test, and if the pipe successfully withstands the required pressure without any signs of leakage, it is considered to have passed the test. In addition to hydrostatic testing, other non-destructive testing methods may also be employed. These methods include ultrasonic testing, which uses high-frequency sound waves to detect any flaws or defects in the pipe material, and magnetic particle testing, which involves applying a magnetic field to the pipe and inspecting it for any magnetic particles that may indicate cracks or imperfections. Moreover, visual inspection is an essential step in testing steel pipes for pressure and leakage. Trained inspectors examine the exterior and interior surfaces of the pipe to check for any visible signs of damage, such as corrosion, cracks, or faulty welds. This visual inspection helps to identify potential weak points that could lead to leaks or failures under pressure. Overall, a combination of hydrostatic testing, non-destructive testing methods, and visual inspection is used to comprehensively evaluate steel pipes for pressure and leakage. These rigorous testing procedures ensure that the pipes meet the required standards and are safe for their intended applications.

1. Manufacturer Overview |

|

|---|---|

| Location | Tianjin, China |

| Year Established | 2001 |

| Annual Output Value | 500,000Tons |

| Main Markets | Southeast Asia; Middle East; Oceania; Americas; Europe; Africa;etc. |

| Company Certifications | API 5L;API 5CT;ISO9001:2008 GB/T 19001-2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin;Qingdao |

| Export Percentage | 50% - 60% |

| No.of Employees in Trade Department | 1000-1100 People |

| Language Spoken: | English; Chinese; Spanish |

| b)Factory Information | |

| Factory Size: | Above 150,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

SSAW Welded Steel Pipes API SEPC 5L API SPEC 5CT ASTM A53

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- based on order m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords