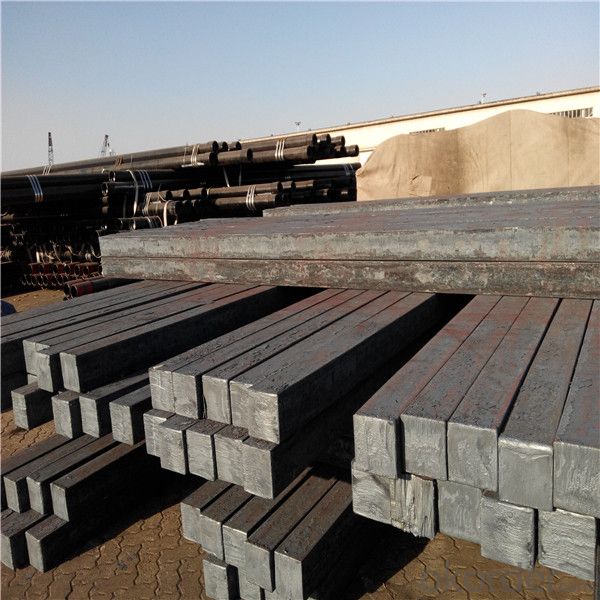

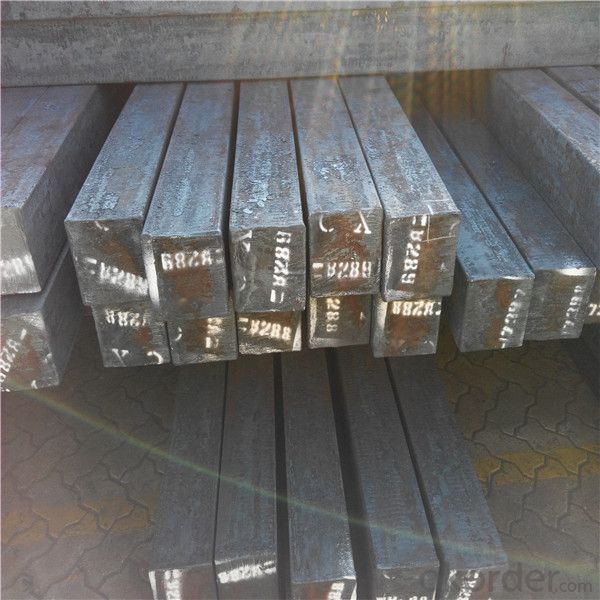

Square Steel Billets hot sale Q275 grade

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Steel billet

(ingot) by cogging or breakdown of semifinished products, is the raw material of all kinds of steel mill.

Billet section of square, round, flat, rectangular and abnormity of several kinds of, mainly related to the

shape of rolled products.

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Our service :

We have a plant and professional team to provide our best service, from the start of production until the

loading into the vessel, we have a complete quality follow up procedure, to assure our products arrives to the customer with satisfaction. Welcome new and old customers

to contact us for future business relationships! We will give you a surpise price.

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: What is payment terms?

A: FOB 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T BEFORE SHIPMENT

CIF and CFR 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T AS THE COPY OF B/L OR L/C AT SIGHT

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q:What are the different surface treatments for improved surface lubrication in steel billets?

- There are several surface treatments that can be applied to steel billets to improve surface lubrication. These treatments aim to reduce friction and wear during various manufacturing processes, such as rolling or extrusion. Some of the common surface treatments for improved surface lubrication in steel billets include: 1. Phosphating: This treatment involves the application of a phosphate coating to the steel surface. Phosphating creates a thin layer of a phosphate compound, which acts as a lubricant and reduces friction between the billet and the machinery during processing. 2. Nitriding: Nitriding is a process that introduces nitrogen into the steel surface, forming a nitride layer. This layer improves the surface hardness and wear resistance of the billet, enhancing its lubrication properties and reducing friction. 3. Electroplating: Electroplating involves depositing a layer of metal, such as zinc or nickel, onto the steel billet's surface. This coating not only improves lubrication but also provides corrosion protection, extending the lifespan of the billet. 4. Surface coating: Various types of coatings, such as Teflon or other polymer-based coatings, can be applied to steel billets. These coatings create a low-friction surface, preventing sticking or galling during processing. 5. Shot peening: Shot peening is a mechanical surface treatment that involves bombarding the steel surface with small, high-velocity metal shots. This process induces compressive stress in the surface layer, increasing its resistance to wear and reducing friction. 6. Case hardening: Case hardening is a heat treatment process that involves the diffusion of carbon or other alloying elements into the steel surface. This treatment forms a hardened outer layer, which enhances lubrication properties and reduces friction during processing. Overall, these surface treatments for improved surface lubrication in steel billets offer various advantages, such as reduced wear, improved efficiency, and extended tool life. The choice of treatment depends on the specific application requirements and the desired properties of the billet.

- Q:How are steel billets used in the manufacturing of valves and pumps?

- Steel billets are an essential raw material used in the manufacturing of valves and pumps. Billets are semi-finished steel products that are cast into a specific shape, usually in the form of a square or a rectangle. These billets serve as the starting point for the production of valves and pumps. To manufacture valves, steel billets are first heated and then forged or rolled into the desired shape. The billets undergo a series of processes such as cutting, drilling, and machining to form the various components of a valve, including the body, bonnet, disc, stem, and seat. These components are then assembled to create the valve, which regulates the flow of fluids or gases in a system. Similarly, in the manufacturing of pumps, steel billets are heated and shaped into the necessary parts such as impellers, casings, shafts, and housings. These components are then assembled to create a pump, which is responsible for moving fluids or gases from one place to another. The use of steel billets in the manufacturing of valves and pumps is crucial due to the inherent properties of steel. Steel is known for its strength, durability, and resistance to corrosion, making it ideal for applications in industries where valves and pumps are subjected to high pressures, temperatures, and corrosive environments. Furthermore, the versatility of steel allows for customization, enabling manufacturers to create valves and pumps of various sizes, shapes, and specifications to meet the specific needs of different industries and applications. This adaptability ensures that valves and pumps made from steel billets can perform reliably and efficiently in a wide range of environments and conditions. In conclusion, steel billets play a vital role in the manufacturing of valves and pumps. Through the forging, shaping, and assembly processes, steel billets are transformed into the essential components that make up these crucial industrial devices. The use of steel ensures the strength, durability, and corrosion resistance required for valves and pumps to function effectively and withstand demanding operating conditions.

- Q:How do steel billets contribute to the overall durability of a product?

- Steel billets play a crucial role in elevating the overall durability of various products, and their contribution cannot be overstated. These semi-finished steel products serve as raw material for further processing in industries such as construction, automotive, and manufacturing. A key factor in the enhanced durability provided by steel billets is their superior strength and toughness. Steel is renowned for its exceptional mechanical properties, including high tensile strength and resistance to deformation, making it an optimal choice for applications that require durability. By utilizing steel billets as the initial material, manufacturers can guarantee that the final product will possess the necessary strength to endure heavy loads, impacts, and external forces. Additionally, steel billets exhibit outstanding corrosion resistance. With proper processing and treatment, steel can withstand rust and other forms of corrosion caused by moisture, chemicals, or environmental factors. This corrosion resistance significantly enhances the durability of the end product by preventing degradation and extending its lifespan. Another advantage of employing steel billets lies in their versatility for customization. Manufacturers can shape and form the billets into various sizes and dimensions to meet the specific requirements of the product. This flexibility enables the production of components that fit together perfectly, reducing the risk of weak points or vulnerabilities in the overall structure. Furthermore, steel's malleability and ductility allow for easy molding and welding, further enhancing the overall strength and durability of the final product. Furthermore, steel billets undergo stringent quality control measures during the manufacturing process. These measures ensure that the billets meet rigorous industry standards and specifications, guaranteeing their reliability and consistency. The utilization of high-quality steel billets, in turn, contributes to the overall durability of the product by providing a sturdy and dependable foundation. In conclusion, steel billets play a pivotal role in enhancing the overall durability of products. Their exceptional strength, corrosion resistance, versatility, and high-quality attributes make them an optimal choice for industries that prioritize durability. By utilizing steel billets as the raw material, manufacturers can create products capable of withstanding demanding conditions, ensuring longevity and customer satisfaction.

- Q:What are the potential applications of steel billets in the chemical industry?

- Due to their unique properties and versatility, steel billets have numerous potential applications in the chemical industry. One primary use of steel billets in the chemical industry involves their utilization in the production of various types of equipment and machinery. Steel billets can be shaped and forged into different forms, such as pipes, tanks, valves, and fittings, which are crucial for the handling and storage of chemicals. These components need to withstand harsh conditions, including high temperatures, pressures, and corrosive environments, thereby making steel billets an ideal material choice. Additionally, steel billets can be employed in the construction of chemical plants and facilities. They provide exceptional structural support, ensuring the stability and integrity of the buildings. Steel billets are often used in fabricating beams, columns, and other load-bearing elements, providing strength and durability to withstand the chemical processes occurring within the plant. Another potential application of steel billets in the chemical industry pertains to the manufacturing of reaction vessels and reactors. These vessels are utilized for chemical reactions, such as synthesis, distillation, and purification processes. Steel billets can be machined and formed into the desired shape, allowing for the creation of robust and reliable vessels that can handle the high pressures and temperatures often required in chemical reactions. Furthermore, steel billets can be utilized in the production of catalysts used in various chemical processes. Catalysts are substances that expedite chemical reactions without being consumed in the process. Steel billets can serve as a base material for catalysts, providing a stable and durable support structure for the active catalytic components. Moreover, steel billets can be employed in the construction of storage tanks and containers for the transportation and storage of chemicals. Steel billets offer exceptional resistance to corrosion and can be easily welded and fabricated into large containers, ensuring the safe and secure storage of hazardous chemicals. In summary, steel billets possess vast potential applications in the chemical industry. Their strength, durability, and resistance to corrosion make them indispensable materials for various chemical processes and operations, encompassing equipment fabrication, construction projects, catalyst manufacturing, and storage solutions.

- Q:What are the different methods of steel billet surface cleaning?

- There are several methods of steel billet surface cleaning, including shot blasting, pickling, acid cleaning, mechanical cleaning, and electrochemical cleaning.

- Q:What are the main factors affecting the electrical conductivity of steel billets?

- The electrical conductivity of steel billets is primarily influenced by several key factors. 1. Composition: The chemical composition of steel, particularly the presence of alloying elements, significantly affects its electrical conductivity. Elements such as carbon, manganese, silicon, and phosphorus can alter the conductivity properties of steel. 2. Impurities: The presence of impurities in steel, such as sulfur and oxygen, can lower its electrical conductivity. These impurities can create barriers to the flow of electric current within the material. 3. Grain structure: The grain structure of steel, which is influenced by factors like temperature and cooling rate during the manufacturing process, can impact its electrical conductivity. A fine-grained structure generally results in higher conductivity due to the presence of fewer barriers to electron flow. 4. Heat treatment: The heat treatment process applied to steel billets can affect their electrical conductivity. Specific heat treatments, such as annealing or quenching, can modify the microstructure of the material and consequently impact its conductivity. 5. Temperature: Temperature has a significant effect on the electrical conductivity of steel billets. Generally, as temperature increases, the conductivity decreases due to increased thermal vibrations that impede the flow of electrons. 6. Surface conditions: The surface condition of steel billets, including the presence of oxides, scale, or contaminants, can influence their electrical conductivity. A clean and smooth surface promotes better conductivity by reducing any barriers to electron flow. 7. Mechanical stress: The presence of mechanical stress or strain in steel billets can affect their electrical conductivity. Deformation caused by processes such as rolling, forging, or bending can alter the material's crystal structure and introduce dislocations, which can impact conductivity. Overall, the electrical conductivity of steel billets is a complex property that is influenced by various factors such as composition, impurities, grain structure, heat treatment, temperature, surface conditions, and mechanical stress. Understanding and controlling these factors is crucial for ensuring the desired electrical conductivity in steel billets for various applications.

- Q:How are steel billets shaped into other forms?

- Steel billets are shaped into other forms through a process called hot or cold working. In hot working, the billets are heated to high temperatures and then shaped using various methods like rolling, forging, or extrusion. Cold working involves shaping the billets at room temperature through processes such as drawing, bending, or pressing. These techniques allow the steel billets to be transformed into different shapes and sizes according to the desired end product.

- Q:How do steel billets contribute to the manufacturing of construction supplies?

- Steel billets play a crucial role in the manufacturing of construction supplies. These billets are semi-finished products that are typically obtained through the process of continuous casting or ingot casting. They are essentially long, rectangular-shaped bars of steel that serve as the raw material for various construction products. One of the primary ways steel billets contribute to the manufacturing of construction supplies is through the production of reinforced bars, commonly known as rebars. Rebars are used extensively in the construction industry to provide strength and structural integrity to concrete structures such as buildings, bridges, and roads. By using steel billets, manufacturers can produce rebars of different sizes and lengths to meet specific construction requirements. Additionally, steel billets are also used in the production of various other construction supplies such as wire rods, pipes, and structural sections. Wire rods, for example, are used in the manufacturing of wire mesh, nails, and other reinforcing materials. Steel billets are also utilized to produce pipes that are widely used in plumbing, drainage systems, and infrastructure projects. Furthermore, structural sections made from steel billets are utilized to create beams, columns, and other load-bearing components in construction projects. The use of steel billets in the manufacturing of construction supplies ensures the final products possess excellent strength, durability, and resistance to corrosion. This is crucial for construction materials as they need to withstand various environmental factors and heavy loads. The versatility of steel billets allows manufacturers to produce a wide range of construction supplies that can meet the specific needs and requirements of different construction projects. In summary, steel billets are instrumental in the manufacturing of construction supplies. They serve as the raw material for producing rebars, wire rods, pipes, and structural sections, all of which are essential components in construction projects. The use of steel billets ensures that these construction supplies possess the necessary strength, durability, and resistance to corrosion, making them suitable for a wide range of construction applications.

- Q:What are the main differences between hot rolled and cold rolled steel billets?

- The main differences between hot rolled and cold rolled steel billets lie in the manufacturing process and resulting properties. Hot rolled steel billets are created by heating the steel and then rolling it at high temperatures, which leads to a rougher surface finish and less precise dimensions. On the other hand, cold rolled steel billets undergo a process of rolling at room temperature, resulting in a smoother surface finish and tighter dimensional tolerances. Moreover, hot rolled steel billets are generally more ductile and have a higher carbon content, while cold rolled steel billets are typically harder and have improved strength due to the strain hardening during the cold rolling process.

- Q:What are the different types of forging processes used for shaping steel billets?

- There are several types of forging processes used for shaping steel billets. Some common ones include open-die forging, closed-die forging, impression-die forging, and seamless rolled ring forging. Each process has its unique characteristics and is suitable for specific applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Square Steel Billets hot sale Q275 grade

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords