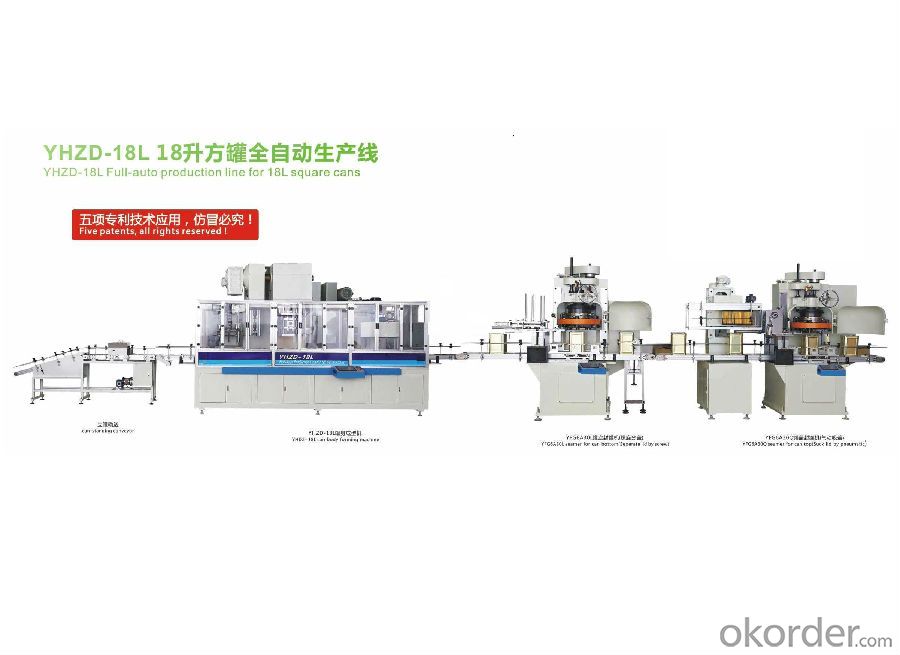

Square Cans Automatic Production Line for Packaging

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Square Cans Automatic Production Line for Packaging

1. Product Description:

It's combined with process of expanding the container into square,angel tendon pressing and cover panelings.the can body is stretched at the same time,which ensures the can body not be contorted,deformed for rebound,and save energy sources.it's mainly used in the one-off forming of the 5-gallon square container body.

2. Product Features:

1)Original manufacturer

2)14 years experience

3)Supply can making line

4)On time delivery

5)Initiative&Proactive service

3. Product Parameters:

Model: | FH18-52ZD |

Linear rate of welding: | 6-36m/min |

Production capcacity: | 60-120cans/min |

Applicable can diameter: | 52-105mm |

Applicable can height: | 70-320mm |

Applicable materical: | tinplate Ni palte |

Applicable materical thickness: | 0.16-0.3mm |

Applicable copper wire diameter: | 0.138-1.5m |

Cooling water: | T:12-18°C P:0.4Mpa D:10L/min |

Power: | 380v±5% 50HZ |

Total power | 18KVA |

Dimension: | 1750*1100*1800mm |

Weight: | 1800kg |

4. FAQ:

Q1: What is your delivery time?

A: Generally, the delivery time is 45-60 days after receive the deposit, big production line may take more time.

Q2: What is the payment term?

A: We accept both T/T and L/C. Most customers pay by T/T.

Q3: What kind of after-sevices do you provide?

A: If it is not big problem, we can solve it by emails, phone etc. If it can’t work, our engineers can go to overseas to install and adjust the machine and solve the problems.

5. Product Pictures:

- Q:What are the main functions of packaging machinery and equipment?

- Sealing and other major operations, and related processes before and after,

- Q:What's the best place to use the pillow type packing machine?

- Suggest that manufacturers can find communication, there is no technical strength,

- Q:What are the packaging machines that use temperature control watches?

- Direct heating sealing machine, blister packing machine, plastic sealing machine, heating pot, oven, toaster and so on

- Q:Packaging machine knife cut out of the mouth is uneven, always inclined, so adjust, now tune not come back, or is unable to cut off, or die!

- Change a new one, in fact, the knife is very simple, and the ordinary knife is very cheap.If you don't understand, you can ask me

- Q:Whether you can press paper plastic molding after PET

- Sure;Note cards must be coated with plastic oil;Can use blister sealing machine or high frequency plastic welding machine hot pressing;

- Q:Color code positioning of packaging machinery

- The main products are: packaging machinery series of quantitative packing machine, vacuum packaging machine, packing machine, strapping machine, sealing machine, bag machine, carton forming machine, packing machine, winding machine, labeling machine, stacking machine, and the design of various transmission lines; at the same time, the production and sale of packing tape, stretch film and other packaging material.

- Q:Vacuum packing machine for cooked food: can whole chicken, whole goose and whole duck be packed?

- Well, yesBut the vacuum packaging machines used for different product sizes are different

- Q:Hello, I just do packaging machinery, foreign trade, I do not know how to search customers ah.For example, our products have machines that can pack candy and cookies. Do you want to search for candy or biscuit manufacturers and then recommend them to our products? These candy manufacturers search through the Internet to recommend, the effect is good?

- You can consider the promotion above the industry website.Plus, you're the packaging machine for candy and cookies, and of course it's the maker of candy and cookies.

- Q:Ask a mechanical problem, the waste film recycling in the packaging machinery is a new film packaging, after cutting, then use the roller to recycle the waste film. Encounter a

- It is suggested that displacement or velocity should be detected on the transport path of the membrane. Is a more reliable control signal. Of course, you can also detect the angular speed of the recovery drum, such as a code dial and other simple institutions.

- Q:What machine does the packing carton machine have?

- Packaging equipment including: automatic strapping machine, automatic sealing machine, winding (wrapping) machine, sealing and cutting / shrink machine, vacuum packing machine, automatic strapping machine band and hand tools. Transport equipment mainly include: conveyor belt, roller conveyor, conveyor chain plate, plug-in production line, chain conveyor, conveyor belt etc..

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Square Cans Automatic Production Line for Packaging

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords