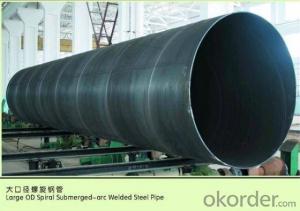

SPIRAL STEEL PIPE 54‘‘ ASTM API LARGE DIAMETER PIPE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Detail: | standard export packing or as customer's requirement |

Delivery Detail: | within 10 - 30 days |

Specifications

Spiral Welded Steel Pipes and Tubes

1.Material:Q195-Q235

2.Length:1-12m

3.WT:1.0-14mm

4.O.D.:20-273mm

Spiral Welded Steel Pipes and Tubes

Product Description:

1.Material : Q235,Q345,L245,L290,L360,L415,L450,L485,GrB,X42,46,X52,X56,X60,X65,X70,X80,X100

2,Standard: SY/T5037-2000,GB/T9711-2011,API Spec 5L PSL1/PSL2,ASTM A252\A53,ISO3183,DIN17172,EN10217,JIS G3457,AWWA C200,ASTM A139,ASTM A671,ASTM A672

3.Wall thickness: 3.0mm-30mm

4.Outer diameter: φ168mm-3020mm

5,Length: 5m-12m or as your requirement

6,Corrosion protection standard: DIN30670,DIN30671, AWWAC210, AWWA C203, SY/T0413-2002,SY/T0414-2002

7,Application: Oil, gas, natural gas, water pipe, thermal electricity pipe, steel structure engineering, etc

Q195-q345 Material Steel Pipe's Materials

Elements | Chemical Compsition% | Mechanical Property | ||||||

C% | Mn% | S% | P% | Si% | Yield Point (Mpa) | Tensile Strength(Mpa) | Elongation | |

Q195 | 0.06-0.12 | 0.25-0.50 | <0.050< span=""> | <0.045< span=""> | <0.030< span=""> | >195 | 315-430 | 32-33 |

Q215 | 0.09-0.15 | 0.25-0.55 | <0.05< span=""> | <0.045< span=""> | <0.030< span=""> | >215 | 335-450 | 26-31 |

Q235 | 0.12-0.20 | 0.30-0.70 | <0.045< span=""> | <0.045< span=""> | <0.030< span=""> | >235 | 375-500 | 24-26 |

Q345 | <0.20< span=""> | 1.0-1.6 | <0.040< span=""> | <0.040< span=""> | <0.55< span=""> | >345 | 470-630 | 21-22 |

- Q:Can steel pipes be used for underground gas storage?

- Yes, steel pipes can be used for underground gas storage. Steel pipes are commonly used for transporting and storing various types of gases, including natural gas, due to their strength, durability, and resistance to corrosion. They are able to withstand high pressures and can be designed to meet the specific requirements of underground gas storage facilities. Additionally, steel pipes can be coated or lined with materials to further enhance their resistance to corrosion and to prevent any potential leaks. However, it is important to ensure that proper safety measures and regulations are followed during the construction and operation of underground gas storage facilities to prevent any potential risks or hazards.

- Q:What is the role of steel pipes in the transportation of petroleum products?

- Steel pipes have a crucial function in the transportation of petroleum products, as they are specifically designed to endure the high pressure and extreme temperatures associated with oil and gas transportation. A primary responsibility of steel pipes in this process is to serve as a dependable and secure conduit for transporting petroleum products over long distances. They are utilized to construct pipelines that span hundreds or even thousands of miles, connecting oil fields, refineries, and distribution centers. Steel pipes are the preferred choice for this purpose because of their strength, durability, and resistance to corrosion. The high tensile strength of steel allows these pipes to withstand the immense pressure exerted by petroleum products as they flow through the pipelines. Additionally, steel pipes can endure extreme temperatures, ensuring the safe transportation of hot crude oil or refined petroleum products. Moreover, steel pipes possess a high resistance to corrosion, which is of utmost importance given the corrosive nature of petroleum products. To further enhance their corrosion resistance, the pipes are often coated with protective materials such as epoxy or polyethylene. This coating helps prevent leaks or ruptures that could cause environmental damage or safety hazards. Steel pipes also offer cost-effective and efficient transportation of petroleum products. They have a smooth interior surface, which reduces friction and allows for a more efficient flow of oil or gas. This, in turn, helps minimize energy consumption and maximize the throughput of the pipeline system. In conclusion, the main role of steel pipes in the transportation of petroleum products is to provide a reliable, secure, and efficient means of transporting oil and gas over long distances. They are designed to withstand high pressure, extreme temperatures, and corrosion, ensuring the safe and efficient delivery of petroleum products from production sites to refineries and distribution centers.

- Q:How do steel pipes handle vibrations?

- The effectiveness of handling vibrations is a well-known attribute of steel pipes. Their strong and rigid nature enables them to withstand various types of vibrations, including mechanical vibrations and seismic activities. The structural integrity and strength of steel pipes are responsible for their resilience. Steel pipes possess high tensile strength, which allows them to resist deformation or breakage when exposed to vibrations. They also exhibit resistance to fatigue, meaning they can endure repeated vibrations without suffering significant damage. This quality makes steel pipes ideal for applications involving constant or cyclic vibrations, such as in industrial settings or for fluid transportation through pipelines. Furthermore, steel pipes have the added advantage of being able to dampen vibrations due to their mass. The weight of the steel pipe aids in absorbing and dissipating the energy generated by vibrations, preventing excessive movement or oscillation. This damping effect contributes to the overall stability and durability of the pipe system. Various measures can be taken to further enhance the ability of steel pipes to handle vibrations. These measures may include the utilization of vibration isolators or dampers, which are devices designed to reduce the transmission of vibrations from the surrounding environment. Additionally, proper installation techniques and regular maintenance can help ensure that steel pipes continue to function optimally under conditions prone to vibrations. In conclusion, steel pipes possess the necessary attributes to effectively handle vibrations, including strength, resistance to fatigue, and the ability to dampen vibrations. Their robustness and durability make them a reliable choice for applications where vibrations are a concern, guaranteeing the safe and efficient transportation of fluids or materials.

- Q:How are steel pipes used in transportation?

- Steel pipes are commonly used in transportation for various purposes such as the construction of pipelines for oil, gas, and water transportation. They are also used for structural support in bridges, tunnels, and railway tracks. Additionally, steel pipes are utilized in the manufacturing of vehicles, including exhaust systems, chassis, and frames, ensuring durability and reliability in transportation infrastructure.

- Q:Are steel pipes suitable for HVAC systems?

- Indeed, steel pipes prove to be a suitable option for HVAC systems. HVAC applications widely favor steel pipes due to their numerous advantages. Initially, their robustness and durability enable them to endure the high pressure and temperature requirements commonly associated with HVAC systems. Furthermore, steel pipes exhibit exceptional resistance to corrosion, rendering them suitable for both indoor and outdoor installations. Moreover, their extended lifespan significantly reduces the need for frequent replacements or repairs. Additionally, the availability of steel pipes in various sizes and thicknesses facilitates effortless customization and installation. Lastly, steel pipes offer a cost-effective solution for HVAC systems compared to alternative materials, making them a financially efficient choice. In conclusion, steel pipes emerge as a reliable and appropriate selection for HVAC systems due to their strength, durability, corrosion resistance, availability, and cost-effectiveness.

- Q:What are the safety precautions to consider when working with steel pipes?

- When working with steel pipes, it is important to follow several safety precautions. Firstly, always wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots to protect yourself from potential injuries. Additionally, ensure that the work area is well-lit and clear of any obstructions to prevent tripping hazards. It is crucial to use proper lifting techniques or mechanical lifting equipment when handling heavy steel pipes to prevent strains or back injuries. Furthermore, be cautious of sharp edges or burrs on the pipes, as they can cause cuts or punctures. Finally, when working with welding or cutting equipment, make sure to follow proper procedures and wear appropriate flame-resistant clothing to prevent burns or fire hazards. Overall, prioritizing safety measures and being aware of potential risks are essential when working with steel pipes.

- Q:How do steel pipes handle ground settlement?

- One possible alternative: Due to their robustness and durability, steel pipes are highly suitable for managing ground settlement. The pipes' flexibility and strength enable them to endure the shifting and settling of the ground with minimal damage. Their high resistance to deformation ensures that they can maintain their shape and structural integrity even when the ground settles or moves. When the ground settles, steel pipes can flex and bend slightly to accommodate the movement. This flexibility allows them to adapt to changes in the ground without experiencing breakage or cracking. Additionally, steel pipes often incorporate joints designed to absorb and distribute stress caused by ground settlement. Moreover, steel pipes possess a smooth interior surface that reduces friction and resistance to material flow. This characteristic becomes particularly crucial when the ground settles, as it diminishes the chances of blockages or clogs due to debris or sediment settling inside the pipes. In conclusion, steel pipes possess the necessary strength, flexibility, and resistance to deformation to effectively handle ground settlement. They can adapt to ground movement without compromising their structural integrity, making them a dependable choice for various applications such as underground infrastructure and pipeline systems.

- Q:What is the difference between standard wall thickness and extra-strong wall thickness steel pipes?

- Standard wall thickness steel pipes have a thickness that meets the minimum requirements set by industry standards, while extra-strong wall thickness steel pipes have a thicker wall, exceeding the minimum requirements. This difference in wall thickness makes the extra-strong pipes more robust, durable, and able to withstand higher pressure and stress compared to standard wall thickness pipes.

- Q:What are the different sizes of threads available for steel pipes?

- The different sizes of threads available for steel pipes can range from 1/8 inch to 4 inches, with various standard sizes in between.

- Q:How are steel pipes transported?

- Steel pipes are typically transported using various methods, including trucks, trains, and ships. They are often loaded onto flatbed trucks or railcars for land transportation, while larger quantities are transported by bulk carriers or container ships for overseas shipping. The pipes are secured with straps or chains to ensure safe and stable transport, and they may also be packed in bundles or placed in specially designed containers to protect them from damage during transit.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

SPIRAL STEEL PIPE 54‘‘ ASTM API LARGE DIAMETER PIPE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords