Spiral plate heat exchanger(Detachable)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The spiralplate heat exchanger is a high-efficient heat exchanging equipment used inalcohol, solvent, food ferment, pharmaceutical, petrochemical, refrigeration,organic chemistry, metallurgical industry, suitable for convection heattransfer of liquidtoliquid,gas to gas, gas to liquid.

The spiralplate heat exchanger comprises detachable and nondetachable exchanger. Thespiral plate heat exchanger is made of carbon steel and stainless steel.

The argument list of carbon steel spiral plate heat exchanger

公称换热面积m2 | 通道间距m2 | 计算换热面积m2 | 流速1m/sec时处理量m3/h | 接管公称直径dg | 型 号 | 质 量(kg) I6T型 II6T型 | |

40 | 10 | 40.9 | 20.9 | 80 | I6.II6T40-0.6/1200-10 | 1730 | 2772 |

14 | 42.3 | 39.3 | 100 | I6.II6T40-0.8/1200-14 | 1843 | 2835 | |

18 | 44.9 | 63.5 | 125 | I6.II6T40-1.0/1200-18 | 2069 | 3061 | |

50 | 10 | 50.2 | 35.3 | 100 | I6.II6T50-1.0/1000-10 | 2334 | 3070 |

14 | 53.2 | 49.4 | 125 | I6.II6T40-1.0/1200-14 | 2408 | 3400 | |

18 | 54.0 | 76.3 | 125 | I6.II6T40-1.2/1200-18 | 2430 | 3422 | |

60 | 10 | 60.8 | 20.9 | 80 | I6.II6T60-0.6/1400-10 | 2673 | 4231 |

14 | 60.7 | 39.3 | 100 | I6.II6T60-0.8/1400-14 | 2750 | 4308 | |

18 | 61.6 | 63.5 | 125 | I6.II6T60-1.0/1400-18 | 3097 | 4655 | |

80 | 10 | 81.4 | 28.1 | 100 | I6.II6T60-1.0/1400-10 | 3365 | 4923 |

14 | 80.6 | 39.3 | 100 | I6.II6T80-0.8/1600-14 | 3445 | 5796 | |

18 | 82.0 | 63.5 | 125 | I6.II6T80-1.0/1600-18 | 3682 | 6033 | |

100 | 10 | 101.4 | 28.1 | 100 | I6.II6T100-1.0/1600-10 | 4250 | 6601 |

14 | 101.8 | 49.4 | 125 | I6.II6T100-1.0/1600-14 | 4390 | 6741 | |

18 | 108.2 | 76.3 | 125 | I6.II6T100-1.2/1600-18 | 4460 | 6811 | |

120 | 14 | 121.5 | 42.5 | 125 | I6.II6T120-1.2/1700-14 | 5130 | 7718 |

18 | 120.0 | 59.4 | 125 | I6.II6T120-1.2/1800-18 | 5250 | 7960 | |

130 | 14 | 130.5 | 32.5 | 125 | I6.II6T130-1.2/1800-14 | 5570 | 8280 |

18 | 131.0 | 49.4 | 125 | I6.II6T130-1.2/1900-18 | 5700 | 9005 | |

2.New Technology Description:

Five-ColumnThree-Effect Distillation Process

Our company designs and manufactures latestFive-ColumnThree-Effect Distillation equipment.This new process is promoted on the basisof traditional five-column differential-pressure column and mainly used forsuper-fine alcohol production.

The key of this process is the heatingmethods,the steam heats one column directly andtransfers theheat to other 4 columnsto achieve three-effect thermal couplingand energy-saving effects.

In terms of electricityefficiency, it can save 50% electricity and avoid the repairing ofcirculating pumps and also extend the working life of there-boilers.

Energy Consumption & Quality Indicator Table forSuper-fine Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗汽量Steam Consumption | t/t | 3.0 | 2.3 |

2 | 色度Colority | No. | 9.5 | 8 |

3 | 乙醇 Alcohol | %(v/v) | 95.5 | 96.5 |

4 | 硫酸试验Sulfuric Acid Test | No. | 70 | 9 |

5 | 醛(以乙醛计)Aldehyde (as acetaldehyde) | mg/l | 28 | 2 |

6 | 甲醇Methanol | mg/l | 18 | 3 |

7 | 正丙醇n-propyl alcohol | mg/l | 15 | 2 |

8 | 异丁醇+异戊醇Isobutanol+isoamylol | g/l | 27.5 | 2 |

9 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 9 |

10 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 16 |

11 | 不挥发物Nonvolatile matter | mg/l | 23 | 12 |

12 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.4 |

13 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 2 |

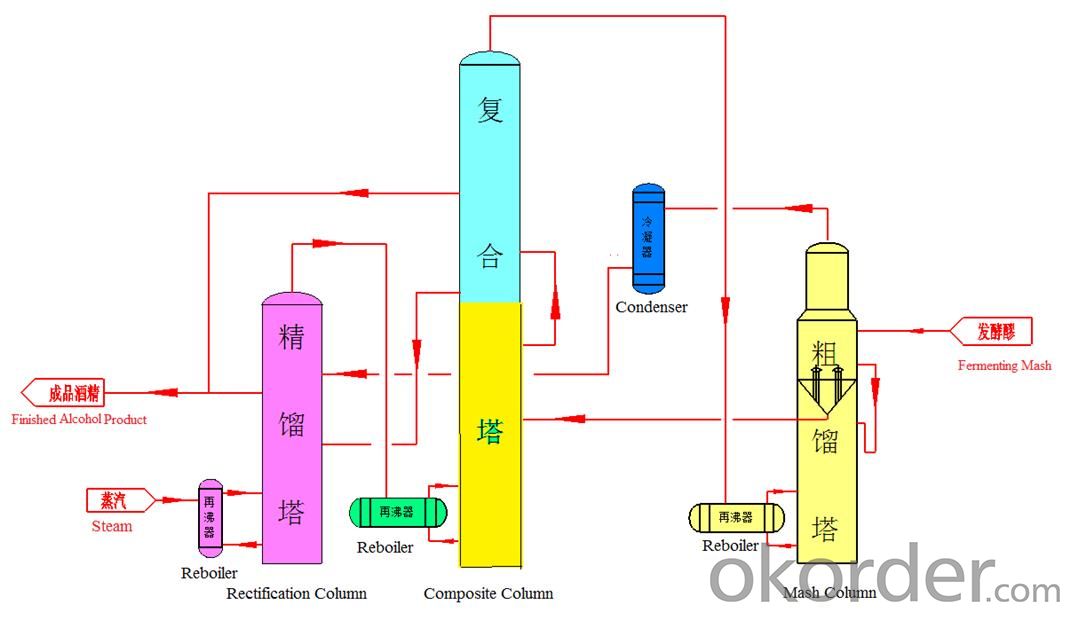

Double-Mash-Column Three-Effect Distillation Process

This process applies to the production ofgeneral-grade alcohol& fuel ethanol, and it was awarded Chinese nationalpatent, it is the onlysuccessfulapplicationof doublemash column & three-effect in the world,whichproduces general-grade alcohol.

This process is composed by mash column,rectification column and composite column. The composite column functions asmash column and rectification column.

The key of this process is the heatingmethods: the steam heats one column directly andtransfers the heat to other 2 columns to achieve three-effect thermal couplingand energy-saving effects.

The advantage of this process is energy-saving;itsaves over 40% steam

Energy Consumption & Quality Indicator Table for General-Grade Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗电量Electricity Consumption | kwh/t | 15 | 20 |

2 | 耗汽量Steam Consumption | t/t | 2.3 | 1.4 |

3 | 耗水量Water Consumption | t/t | 7 | 5 |

4 | 色度Colority | No. | 9.5 | 8 |

5 | 乙醇 Alcohol | %(v/v) | 95.5 | 95.5 |

6 | 硫酸试验Sulfuric Acid Test | No. | 70 | 55 |

7 | 醛Aldehyde (as acetaldehyde) | mg/l | 28 | 25 |

8 | 甲醇Methanol | mg/l | 100 | 55 |

9 | 正丙醇n-propyl alcohol | mg/l | 75 | 35 |

10 | 异丁醇+异戊醇Isobutanol+isoamylol | mg/l | 27.5 | 26 |

11 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 18 |

12 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 20 |

13 | 不挥发物Nonvolatile matter | mg/l | 23 | 21 |

14 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.5 |

15 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 3 |

3. Production Capability

1. Our company was established in the 1950s,designed and manufactured the first stainlesssteel distillation column in China.

2. Our company can produce6 full sets of equipment (including crushing section, liquefyingsaccharification section, fermentation section, distillation section and DDGSsection) in a

month.

3. Among 16 production workshops,3 workshops arefor mechanic manufacture, 5 workshops arefor manufacturing process, 8 workshopsare for assembling & welding.

4. We own advanced machining equipment and producttesting equipment.

4. Designed capability

1). We own Design License of SpecialEquipment D1 & D2 Class; Manufacture License of Special Equipment A2 Class;Design License of Special Equipment GC

Class.

2).Our company achieves more than 20 patentcertificates on distillation, DDGS, and other fields.

3). Ourcompany owns ASME certification, ISO 9001 Quality System Certification, ISO14001 Environmental Management System Certification & GB/T28001Occupational Health and Safety

Management System Certification

5. After-sales Service

1).Our company can provide a sophisticatedproduct after-sale service and can ensure the implementation, maintenance andcommission of projects.

2). We can reach the project site afterreceiving the user’s notification.

6.Package & Transport

- Q:I have heard in some countries such as the USA this system is not allowed anymore to use in residential buildings because of some none healthy issues . is it true ? and do you know which countries else don't accept this system as a standard heating system ?

- Underfloor heating systems are becoming very popular in the US. There are no health issues at all...

- Q:I just got a job at a company that fabricates pressure vessels and heat exchangers.

- okorder and get some brochures in the sites listed. If you are hesitating in this perhaps you should go back to college :>

- Q:Over the weekend the heat was working. During the night on Friday, the primary ignition reset tripped (little red button). I reset it and the blower comes on and it sounds like the electrode are firing but the furnace does not light.The fuel filter and nozzle were both replaced last year. I haven't done it yet this season. I think it might be a fuel issue rather than an electrical one...any ideas?

- If the limit tripped out (the thing you pressed the button on) you need to determine if it was simply a part failure or if you have another pressure issue, such as a cracked heat exchanger, poor return (lack of air flow, block flue. I would call a professional, while the parts do fail over time, I would suspect you might have another issue at hand. But just from the sounds of it you have a bad limit switch and may have more than one that is bad. Some have the little button on like what you push, while the other style self resets upon cool down. After so many cycles of tripping the switch will fail and will not auto reset of that makes sense. You might need to call a pro in for this one, and verify that you dont have something else going on that your not aware of.

- Q:seperate water cylcle that is entirley outside the reactor. Why is this done

- The water in the reactor becomes radioactive. The heat is passed through a heat exchanger to a different set of water tubes for the steam turbine. Then if steam is released it is not radioactive.

- Q:I was told that if you let the fan continue to run after a furnace shuts off, the fan circulates the residual heat in the heat exchanger, thus making the air warmer to heat the next time and getting the most for your furnace running time.

- most furnace have this built in. They run for approx 90 sec. after the flame is out to move the residual heat.

- Q:what needs to be verified in deminstions, materials or others if both ST exchangers are used for the same service?

- Well, lots of things need to be verified. First, practically speaking, the dimensions must be such that the replacement bundle can fit into the existing shell. Second, look at it from a fluid flow perspective. The dimensions must be such that the the flow will be alterred outside of allowable specifications. The pump in the system will have been sized based on overall pressure drop of the system, so you would need to verify that the drop will not adversely alter performance of the loop or choke the flow. Third, look at the heat transfer issues. The heat transfer is most likely practically independent of the tube material, but it is good practice to verify that the heat conduction of the two tube materials are similar. More important (as in the fluid considerations) is the length and diameter of the flow. The longer the tubes, the more heat will be transferred, and vice versa. The diameter of the tube will affect the amount of heat transferred as well. You would generally want to have the same efficiency of heat removal as the original exchanger. Of course that depends on what is downstream as well. Perhaps you may want to remove more heat? Fourth, from a material perspective, you should ensure that you aren't introducing any reactions into the system. Meaning, don't use anything that will react with whatever you are flowing through the shell or the tube. Also, the adaptation may be tricky from a construction perspective. Just use the tubes that were built for the exchanger. Why is this not an option? Is it old equipment? Why not just fabricate a replacement to specification of the original tubes?

- Q:when the furnace comes on sometimes it makes a popping sound blowing noise any answers

- popping noise , blowing noise could be a crack in your heat exchanger. You need to get that checked Big poof is a bit different then popping sounds. A poof would indicate a build up in gas before it lights. That is very dangerous. If its proofing I'd shut it down. I'd shut it down for a crack as well you need to have it checked either way. Anyone with headaches or feeling bad?

- Q:how this LMTD differs from LMTD of 1-2 shell tbe heat exchanger??

- How To Calculate Lmtd

- Q:I live in a house that is very well insulated, consequently the heating/cooling costs are very reasonable, and I'm grateful for that. However, I'm becoming concerned with the quality of indoor air - specifically if the oxygen levels are dropping because the house is not getting the recommended number of air changes per hour, especially in winter months. I'm considering ventilation with a heat exchanger to insure adequate O2 levels, but I'd like to see if I really have a problem before I invest.I would like to find a reasonably priced indoor oxygen meter/monitor, that I can use for an occasional spot check. Anybody have a source?

- keep in mind that no matter how much oxygen they give off during the day they create almost the same amount of carbon dioxide at night and the inside light is not bright enough for the plants to photosynthesis enough to be an oxygen producing machine you want. And if they would be able to create the amount of pure oxygen you want, the room would have to be airtight to see a benefit

- Q:In a geothermal heat pump system, it indicates use of high density polyethylene. But pipes should be able to conduct heat.. Isnt polyethylene a poor conductor of heat?? Then why are they used here?? If not, which would be the most adequate material??

- nicely u see, its relatively user-friendly, blah blah blah blah blah blah blah blah blah blah blah blah blah blah blah blah, and that's how warmth is extracted from the living house for the time of the cooling technique.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Spiral plate heat exchanger(Detachable)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords