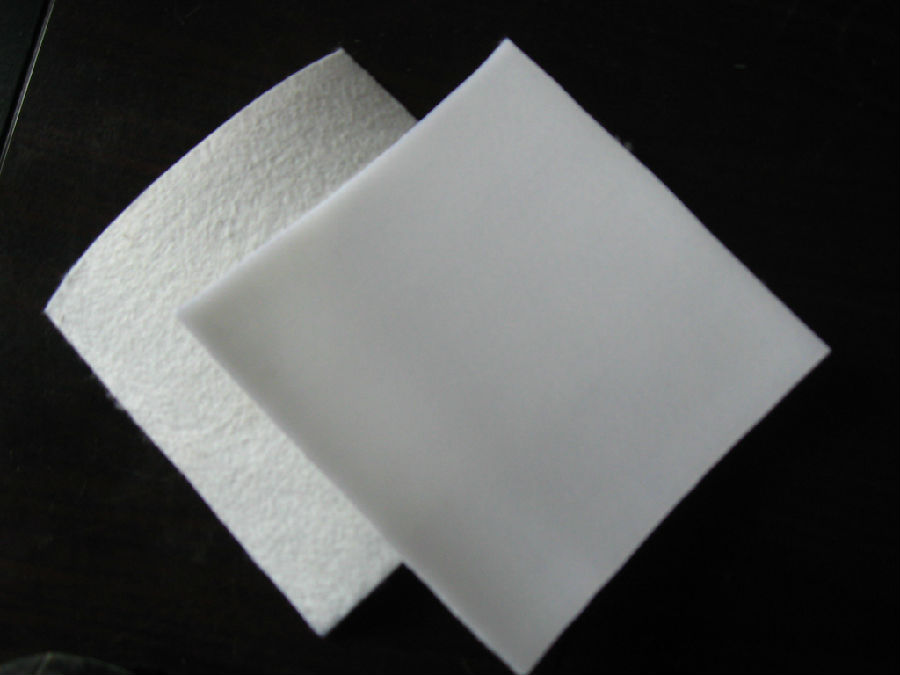

Specifications of Needle Punched Nonwoven Geotextile for Highway Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application of Needle Punched Nonwoven Geotextile for Highway Construction:

1. Water conservancy projec: seawall, dike,river canal engineering;Reservoir reinforcement engineering; Reclamation engineering; Flood control engineering.

2.Highway,railway and airport project: soft foundation reinforcement; Slope protection; Pavement structure layer reflective crack prevention; Drainage system; Greening belt.

3.Electrical engineering : Nuclear infrastructure;Thermal power ash dam project;Hydropower project.

Technical Data Sheet of Needle Punched Nonwoven Geotextile for Highway Construction:

Index Spec.

Article | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |

1 | Quality error in unit area,% | -6 | -6 | -6 | -5 | -5 | -5 | -5 | -5 | -4 | -4 | -4 |

2 | Thickness,mm≥ | 0.8 | 1.2 | 1.6 | 1.9 | 2.2 | 2.5 | 2.8 | 3.1 | 3.4 | 4.2 | 5.5 |

3 | Width error,% | -0.5 | ||||||||||

4 | Breaking strength,KN/m≥ | 4.5 | 7.5 | 10.0 | 12.5 | 15.0 | 17.5 | 20.5 | 22.5 | 25.0 | 30.0 | 40 |

5 | Elongation at break,% | 40~80 | ||||||||||

6 | CBR puncture strength,KN≥ | 0.8 | 1.4 | 1.8 | 2.2 | 2.6 | 3.0 | 3.5 | 4.0 | 4.7 | 5.5 | 7.0 |

7 | Effective aperture 090(095),mm | 0.07~0.2 | ||||||||||

8 | Vertical permeability coefficient , cm/s | K X (10-4-10-3) K=1.0~9.9(K=1.0~9.9) | ||||||||||

9 | Tearing strength,KN≥ | 0.14 | 0.21 | 0.28 | 0.35 | 0.42 | 0.49 | 0.56 | 0.63 | 0.70 | 0.82 | 1.1 |

FAQ:

What is the main application of Needle Punched Nonwoven Geotextile for Highway Construction?

The main application of our Needle Punched Nonwoven Geotextile for Highway Construction is as follows: The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc.

Where is your main market?

Our main market is in Middle East, South America and some African countries.

What is your advantages for Needle Punched Nonwoven Geotextile for Highway Construction?

One of the largest manufacturer of Needle Punched Nonwoven Geotextile for Highway Construction with advanced equipment, big production capacity and excellent quality.

Over the past decade a greater emphasis has been placed on the development and manufacturing of geosynthetic textiles. While the geosynthetics industry is comparatively new, it has already created products with applications in a wide range of industries including geotechnical, transportation, hydraulic, embankment management, and mining. In many cases, a single geosynthetic textile can solve or improve multiple civil engineering problems simultaneously.

The first example of a geosynthetic textile application is the use of a prefabricated pocket style vertical drain made from a nonwoven filter jacket specialized as a PVD filter material. The purpose of this product was to reduce the time needed for construction by quickly discharging water in the ground which speeds up the soil consolidation process. Overall, it proved to reduce construction time and speed up the consolidation of soft ground in a variety of different situations including road construction, the development of building sites, construction of gas and oil storage facilities, and bank revetment.

The second example of how geosynthetic textiles can provide solutions to civil engineering problems is the polyester woven geotextile mat. It is created from a high tenacity polyester filament which is highly dense. This particular geosynthetic textile has been used to reinforce soft ground and embankments, separate layers of sand and soft ground, prevent the uneven settlement of soft ground, and securing a safe path of travel for heavy equipment across soft ground.

The third example is a silt curtain or fence created by geosynthetic textiles. A silt curtain is installed in the water to prevent the spread of environmentally dangerous contaminants. These contaminants often result from coastal and Riverside construction projects although it can also be used in the event of an open water spill or leak. It has been shown effective at preventing the spread of fine soil and sand induced by construction. It can also prevent the contamination of the nearby seaports and help preserve sea farming and area beaches.

The fourth and final example of geosynthetic textiles assisting with civil engineering problems is the polyester needle punched nonwoven geotextile. It is typically made of continuous filament fiber to promote fast drainage and filtration. It has been used to help prevent landslides, control erosion on banks, protect waterproof layers in landfills, prevent road tracking, and protect waterproof sheets and tunnels.

There is no doubt geosynthetic textiles will continue to play a greater role in finding workable solutions to civil engineering problems across the globe. As their production continues to scale, prices will decrease which will lead to an increase in availability as well as further research and development.

- Q:JTGF80 / 1-2004 "standard" 4.5 Geosynthetics in the treatment of the measured items in the "anchoring length", in the construction design diagram, the provisions of the value of the allowable deviation should be how to implement? Question added: Sorry! I missed a few words. When the construction design is not indicated, the specified value, the allowable deviation value should be implemented? JTGF80 / 1-2004 "standard only write to meet the design, construction requirements. I did not say that the design of the length of the anchorage is how much, can not find the construction technical specifications. So I do not know the provisions of the value of how to allow deviation? More

- Specifically not less than the specified value, does not exceed the allowable deviation. This is the so-called construction by specification! You refer to JTG assessment standard -2004 is correct! I have the data to let you refer to the next / geogrid and geotextile landscape is greater than or equal to 50cm, vertical is greater than or equal to 150com

- Q:How do geotextiles help with load transfer in foundation systems?

- Geotextiles improve load transfer in foundation systems by distributing the load from the structure to a wider area, reducing the stress on the underlying soil and preventing soil settlement. They also help to reinforce weak or unstable soils, enhancing their load-bearing capacity and stability.

- Q:What is the number of tensile units for geotextiles

- Personal sense of the number of stretching units is mainly for the sparse geotextile geotextile, geotextile, geogrid or other similar loose structural materials, sample 1m width of the number of stretching units is 1m width of the number of holes or how many cells, The number of stretched units within the test is the number of holes or the number of cells in the test width. For example, geotextile geogrid 1m width of 25 holes, the number of stretching unit is 25, the sample width of 200mm with 5 holes, the number of drawing unit is 5, C = Nm / Nsc = 25/5 = 5 individuals Understanding is not necessarily advice

- Q:Can geotextiles be used in coastal erosion control structures?

- Yes, geotextiles can be used in coastal erosion control structures. Geotextiles are commonly used to stabilize slopes, reinforce soil, and control erosion in various construction projects. In coastal areas, they can be employed to prevent erosion of beaches, dunes, or shorelines by acting as a barrier against the movement of sediment and soil. Geotextiles provide an effective solution for coastal erosion control structures due to their permeability, strength, and ability to withstand harsh environmental conditions.

- Q:Will the HDPE geomembrane, non-woven geotextile re-examination to detect what project? Is there a basis for testing? Thank you, hurry! The The

- CBR top breaking strength, vertical permeability coefficient ,,

- Q:Are geotextiles resistant to fire damage?

- Yes, geotextiles are generally resistant to fire damage. They are often made from materials such as polypropylene or polyester, which have inherent fire-resistant properties. Additionally, geotextiles can be treated with flame retardant additives to enhance their resistance to fire damage. However, it is important to note that the level of fire resistance may vary depending on the specific type and composition of the geotextile.

- Q:Geotextile is what kind of material in the construction? Is it a hydroelectric material?

- Geotextile, also known as geotextile, it is made of synthetic fibers through the needle or woven from the permeability of geosynthetics. Finished cloth for the cloth, the general width of 4-6 meters, the length of 50-100 meters. Geotextile is divided into a woven geotextile and non-woven geotextile. Geotextile has excellent filtration, isolation, reinforcement protection, high tensile strength, good permeability, high temperature, anti-freeze, anti-aging, corrosion resistance.

- Q:How do geotextiles help with soil reinforcement in retaining wall applications?

- Geotextiles help with soil reinforcement in retaining wall applications by providing additional strength and stability to the soil. They are placed between the soil and the retaining wall to distribute the weight and pressure evenly, preventing excessive soil movement and potential wall failure. Geotextiles also allow water to drain freely, reducing hydrostatic pressure and preventing water accumulation behind the wall, which can weaken the soil and cause erosion. Overall, geotextiles play a crucial role in enhancing the durability and effectiveness of retaining walls by reinforcing the soil and improving drainage.

- Q:What kind of geotextile is used to repair the road?

- Geotextile in the application of the road: a slope care, specifications in the 250-350g / m2 its role has the following three points: 1. filter when the water from the fine soil into the coarse soil layer, the use of polyester staple fiber Acupuncture geotextile good permeability and water permeability, so that water through, and effectively carrying soil particles, sand, small stone, etc., in order to maintain the stability of soil and water engineering. 2. Drain polyester staple fiber geotextile has a good water conductivity, it can form a drainage channel within the soil, the soil structure of excess liquid and gas efflux. 3. Protection of water flow on the soil erosion, the effective concentration of concentrated diffusion, transmission or decomposition, to prevent the soil by external forces and damage. Second, the foundation treatment, the main role is to strengthen. The use of polyester staple acupuncture geotextile to enhance the soil tensile strength and resistance to deformation, enhance the stability of the building structure to improve soil quality. Specifications not low 400g / m2. The main role is to use the polyester staple fiber geotextile with different physical properties (particle size, distribution, consistency and density, etc.) of the building materials (such as soil and sand, soil and concrete, etc.) ) To isolate. So that two or more materials are not lost, not mixed, to maintain the overall structure and function of the material, so that the building capacity to enhance the capacity. Specifications in the 150-400g / m2

- Q:What are the different geotextile testing methods?

- There are several geotextile testing methods that are commonly used to evaluate the performance and quality of geotextile materials. Some of these methods include tensile strength testing, puncture resistance testing, tear resistance testing, bursting strength testing, and water permeability testing. These tests help determine the suitability and durability of geotextiles for various applications such as soil stabilization, filtration, and erosion control.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Specifications of Needle Punched Nonwoven Geotextile for Highway Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords