Specialised Refractory Castables For Burner Tube

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Customised solutions for your kilns

2.repair service

3.furnace construction service

4.high mechanical strength

5.ISO9001

1)Refractories for insulation of furnaces and kilns

2)Refractories to meet high-temperature erosion / corrosion

3)Refractories to take high-temperature loads

4)Refractories for continuing improvement in production & performance

5)Refractories for cost-effective manufacturing solutions

Physical & Chemical Properties of Refractory LH-85B

Product Name | Specialized castable for coal burner tube | Corundum Andalusite Castable For Burner | |||

Product Code | LH-80P | LH-85P | LH-70P | ||

Density(kg/m3) | ≥2.75 | ≥2.75 | ≥2.60 | ||

Chemical Component (%) | AL2O3+SiC | ≥75 | ≥80 | ≥70 | |

Cold Crushing Strength(MPa) | 110°C*24h | ≥90 | ≥90 | ≥80 | |

1100°C*3h | ≥100 | ≥110 | ≥90 | ||

1350°C*3h | ≥100 | ≥120 | ≥85 | ||

Modulus of Rupture(MPa) | 110°C*24h | ≥9 | ≥10 | ≥7 | |

1100°C*3h | ≥11 | ≥12 | ≥7 | ||

1350°C*3h | ≥12 | ≥13 | ≥10 | ||

Linear Change Rate(%) | 1100°C*3h | ±0.3 | 0.25± | ± 0.3 | |

1350°C*3h | ± 0.4 | ±0.4 | ±0.4 | ||

Maximum Service Temperature(°C) | 1600 | 1650 | 1600 | ||

Construction Method | Pouring& Vibrating | ||||

Application Area | Coal burner tube and high-temperature parts | ||||

Construction Service & Regulations

1.Check the size, specification, layout, installation and quality of the metal anchorage and make expansion

processing of the anchors.

2.Erect the formworks (hardwood or steel) in advance.

3.Unpacking and pouring the castable

4.Mixing

5.Installation of the mixed castables & Large area constrction

6.Vibrating

7.Before the castable block get final set,it can not bear any pressure or vibration.

8.Curing & Stripping

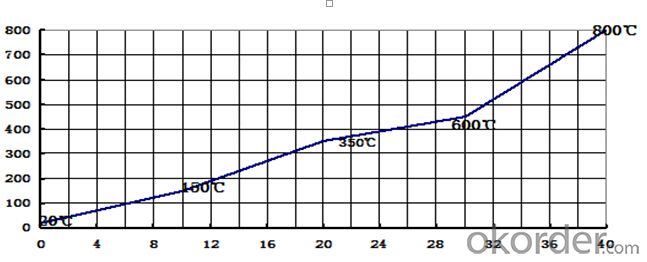

9.Baking the Furnaces (taking cement plant kiln as an example):

1). Keep the initial temperature at 20°C or so.

2). Please strictly follow the curve to conduct the baking work and increase the temperature smoothly and

evenly.

3). Lay out as many temperature measuring points as possible to monitor the temperature in the kiln, ensuring

the stable increase of the temperature.

FACTORY:

- Q:What are the differences between intensive refractory busway and other busways?

- Compact busway is named after its structure, especially referring to busway which is closely laminated between phases and between phase and shell and use thin insulating material to achieve the insulation result. Fire-resistant busway is named after its uses, just as its name implies, for higher fire safety requirements need busway of higher fire resistance level. The structural style of fire-resistant busway can be intensive and of air type, depending on what material it use to resist fire, so there is no direct link between them, but there is a included relationship.

- Q:What is the common inorganic fireproof and thermal inuslation matertial?

- inorganic materials of insulation materials 1, inorganic thermal insulation materials are mainly concentrated in the materials that have a certain insulation effect and can achieve level A fireproofing, such as aerogel blanket, glass wool, rock wool, expanded perlite and micro-nano thermal baffle. 2, rock wool production is harmful to human body, workers also do not want to occure the situation under the construction. The cycle of rock wool construction plate is long about 2 years from construction to production. The supply of the domestic wool market also cannot meet the requirements for use. 3, expanded perlite has great weight and high water absorption. 4, the insulation performance of micro-nano insulation panels is 3-5 times that of conventional insulation materials, commonly used in high temperature environment, but is more expensive. 5, aerogel blanket is level A1 inorganic fireproofing building materials, thermal conductivity at room temperature is 0.018W / (K · m), and absolutely waterproofing, its insulation performance is 3-8 times of traditional materials, which can replace the unenvironment-friendly froconventional flexible material with poor insulation properties, such as glass fiber products, asbestos insulation felt and silicate products.

- Q:Can anyone tell me what is a high alumina refractory?

- Refractories refer to a class of inorganic non-metallic materials whose refractoriness are no less than 1580 ℃. Refractoriness is the Celsius temperature when cone-shaped samples can resist high temperature without softening and melting down in the absence of a load. But it is not accurate to define refractory merely by judging that whether the refractoriness is no less than 1580 ℃. Currently, the materials whose physical and chemical properties allow them to be used in high temperature environments are called refractories. Refractory materials are widely used in metallurgy, chemical industry, petroleum, machinery manufacturing, power and so on, among which the metallurgical industry is the largest demander in this regard, accounting for 50% to 60% of total output. Hope it will help you out!

- Q:What does refractory mean?

- Ordinary refractories are often used brick, semisilica brick, clay brick, high alumina brick, magnesia brick etc..Special materials often use AZS brick, corundum brick, magnesia chrome brick, silicon carbide, silicon nitride bonded silicon carbide, nitrides, silicides, sulfide, boride, carbide and other non oxide refractory materials; calcium oxide, chromium oxide, alumina, Magnesium Oxide, beryllium and other refractory materials. Often used insulation refractories are diatomite products, asbestos products, insulation panels and so onUnshaped refractory materials commonly used are fettling, refractory ramming material, refractory castable, refractory plastic material, refractory clay, refractory gunning, refractory cast material, fireproof coating, lightweight castable, mud etc..

- Q:Why can aluminium hydroxide not be used to make refractory material?

- Hope my answer is helpful to you. It decomposes and produces aluminium oxide and water after heating, chemical equation for the reaction is: 2Al(OH)3=△=Al2O3+3H2O. Aluminium hydroxide can't be directly used to make refractory material because aluminium hydroxide is not stable.

- Q:What a blast furnace refractories generally?

- Usually metal anchorage plus wear-resistant refractory spray paint. at the middle part we use high alumina bricks, corundum bricks. high duty refractory is important in improving bosh furnace lining.

- Q:What's the fire endurance of fire windows?

- Fire endurance of fire windows: A class fire window: no less than 1.2h; B class fire window: no less than 0.9h; C class fire window: no less than 0.6h. Technical requirements: 1. Materials and fittings: (1) Window frame should adopt the steel frame or wood frame with certain strength so as to guarantee the integrality and stability of the fitting; (2) Steel frame and mound layer can choose the galvanized steel sheet or stainless steel sheet. Its selection standard is in line with provisions of Article 5.1 in GB12955 "General Technical Requirements on Steel Fire Doors"; (3) Selection standard of wood frame and mound layer should be consistent with the provisions of Article 5.1.1 in GB14101 "General Technical Requirements on Wood Fire Doors"; (4) Filler material inside the steel frame and wood frame should be incombustible material; (5) Fireproof glass can choose the qualified product with no influence on the fire resistance test of the fire window, and its light transmittance should be no less than 75% of that of the ordinary sheet glass with the same layers; (6) Sealing material between the frame and the fireproof glass should use flame retardant material which can play the role of fire prevention and smoke control in the case of fire. (7) Hardware fittings should be approved supporting products which is detection qualified.

- Q:What are the differences and connections between softening temperature of the refractory under a fixed load and thermal resistant creep property of the refractory?

- The result of refractoriness under load is temperature while the result of creep is percentage of deformation. Refractoriness under load and creep can be tested by an instrument. Refractoriness under load reflects the temperature in which the deformation reaches a certain degree under the condition of load. Creep reflects the deformation refractory has under the condition of constant temperature and load. Both refractoriness under load and creep are important criterion for the operating temperature of refractory.

- Q:can slag tailings be used to be the base materials of refractory materials ?

- perhaps not, because it has many pores.

- Q:What are the characteristics of magnesium fireproof plate

- Features: Glass magnesium plate is high temperature resistant, sound absorbing, and capable of preventing water, pests, dampness, corrosion, poison, pollution. Paint can directly be applied to the surface of the plate. Air nails are usable for the plate, to which ceramic tile can also be applied with good pigmentation. The plate is easy to decorate, has high strength, good flexibility when bending, and can be nailed, sawed, glued It can also be made into thermal insulation materials with a variety of compround composite insulation plate. Characteristic: Magnesium plate glass is high temperature resistant, sound absorbing, and capable of preventing water, pests, dampness, corrosion, poison, pollution. Paint can directly be applied to the surface of the plate. Air nails are usable for the plate, to which ceramic tile can also be applied with good pigmentation High strength, flexibility when bending, convenient for decoration. It can be sawed, nailed, and glued.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Specialised Refractory Castables For Burner Tube

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords