SPC-K03H Automatic High Speed Carton Erector

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features

1.Precision designed and engineered by expertise. This carton erector has been awarded several patents, and has received approval from famous industries around the world. It is the highest speed carton forming and sealing machine in Taiwan.

2.Fully cam driven continuous system assures positive and stable motion with maximum stability.

3.In a breakthrough for tapping head design, this machine provides extremely secure sealing effect, outstanding tape smoothening performance, without tape slipping problems.

4.Accommodates all type of self-adhesive tapes.

5.Variable speed adjustment for carton forming and sealing. Reducing labor requirements.

6.Easy to operate and adjust. No damage on carton.

7.Horizontal cardboard stacking permits for supply of empty carboard at any time.

8.Automatic indication for tape replacement or cardboard supply.

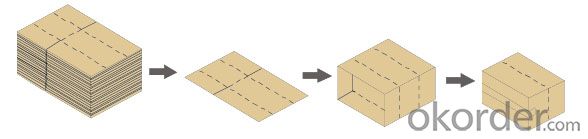

Work Flow Chart

SPC-2500 | Technical Parameters | ||

Model | SPC-K03H40 | SPC-K03H20 | SPC-K03H10 |

Forming and Sealing Speed | 40(cartons)/min | 20(cartons)/min | 10(cartons)/min |

Carton Storage Quantity | 70pcs(700mm) | 100pcs(1000mm) | 50pcs(1000mm) |

Carton Sizes(mm) | L:280-500*W:200-400*H:200-400mm | L:280-500*W:200-400*H:90-400mm | L:200-450*W:150-400*H:100-350mm |

Power Requirements | 750W(AC380V 3F ) | 750W(AC380V 3F ) | 750W(AC380V 3F ) |

Air Compressing | 4~5kg/cm2 | 4~5kg/cm2 | 5~6kg/cm2 |

Air Consumption | 450NL/min | 450NL/min | 150NL/min |

External Sizes | L3540*W1250*H1840mm | L2780*W1250*H1840mm | L2000*W1900*H1200mm |

Machine Weight | 990 kgs | 990 kgs | 350 kgs |

Applicable Tape Size | 1 1/2", 2", 2/12", 3" | 1 1/2", 2", 2/12", 3" | 1 1/2", 2", 2/12", 3" |

- Q:Will the Internet be too passive? Telephone marketing, what kind of food can be found in the factory, such as the phone, people basically do not need, and all have. Does the salesman run the market? How do you run? Thanks for the direction...

- Ha ha, as you say, TV factories are closed down, every household has a TV, but every day there will be a lot of people buy tv.

- Q:Food, equipment, tools, containers, packaging materials, etc. shall comply with food safety standards or requirements

- Graphic symbols for packaging and storageGB/T 5009.60. Analytical method for hygienic standard of polyethylene, polystyrene and polypropylene moldings for food packaging

- Q:Packaging machine knife cut out of the mouth is uneven, always inclined, so adjust, now tune not come back, or is unable to cut off, or die!

- Change a new one, in fact, the knife is very simple, and the ordinary knife is very cheap.If you don't understand, you can ask me

- Q:What is the general packing cost of beer beverage packaging?

- In addition, according to the product's own conditions to set, the packaging machine prices are generally in the range of 3-5 yuan

- Q:The role of packaging equipment in packaging equipment

- (4) it can reduce labor intensity and improve working conditionsThe labor intensity of manual packaging, such as volume, weight heavy manual packaging products, both the consumption of physical strength, and safety; and for small and light products, due to high frequency, easy to make the action monotonous, worker occupation disease.(5) labor protection for workersFor some serious impact on health products, such as serious dust, toxic products, irritating, radioactive products, manual packaging is a health hazard, and packaging machinery can be avoided, and can effectively protect the environment from being polluted.(6) it can reduce the packing cost and save the storage and transportation expensesFor loose products, such as cotton, tobacco, silk and hemp, the compression packing machine can reduce the volume and reduce the packing cost. At the same time, due to the reduction of large volume, in order to save storage capacity, reduce storage costs, is conducive to the transport.

- Q:Whether you can press paper plastic molding after PET

- Sure;Note cards must be coated with plastic oil;But to use the hot pressing machine there is to do bakelite mold. Our company specializing in the production of blister, in addition to help customers hot packaging, directly to the finished products to customers

- Q:What does that mean when the composite material is pressed and molded? What are pressing forming? What are the characteristics of press molding equipment? Its development

- Can be used to shape complex products. The principle is similar to that of injection molding. One is used for thermosetting, heating and cooling in molds, one for thermoplastic, and the other for heating in the barrel and molding cooling in the mold.

- Q:A & B two sets of packaging machines, at the same time packaging quality of 500 kilograms of goods

- (1) calculate the average of two samples;(2) the variance of two samples was calculated;(3) which packaging machine is more stable in packing quality?(1) according to the average, the number divided by the sum of each group;

- Q:What is the name of the paper used in packing machine parts and yellow?

- Also, according to the use of composite PE or textile cloth, in order to improve the physical strength and tightness.Hope to help you.

- Q:What is the design basis of automated packaging?! Just for today!

- Greatly improve the degree of automation of process flowA few years ago, automation technology accounted for only 30% of the design of packaging machinery, now has accounted for more than 50%, a large number of micro computer design and mechanical and electrical integration control. To improve the packaging machinery automation, one is to increase productivity; the two is to improve the flexibility and agility equipment; three is to improve the ability of packaging machinery to complete the complex action, namely the manipulator to complete the packaging process. Such as chocolate packaging has been achieved, with mechanical hand instead of the original manual. Automatic design of packaging machinery has the following two main characteristics:

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

SPC-K03H Automatic High Speed Carton Erector

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords