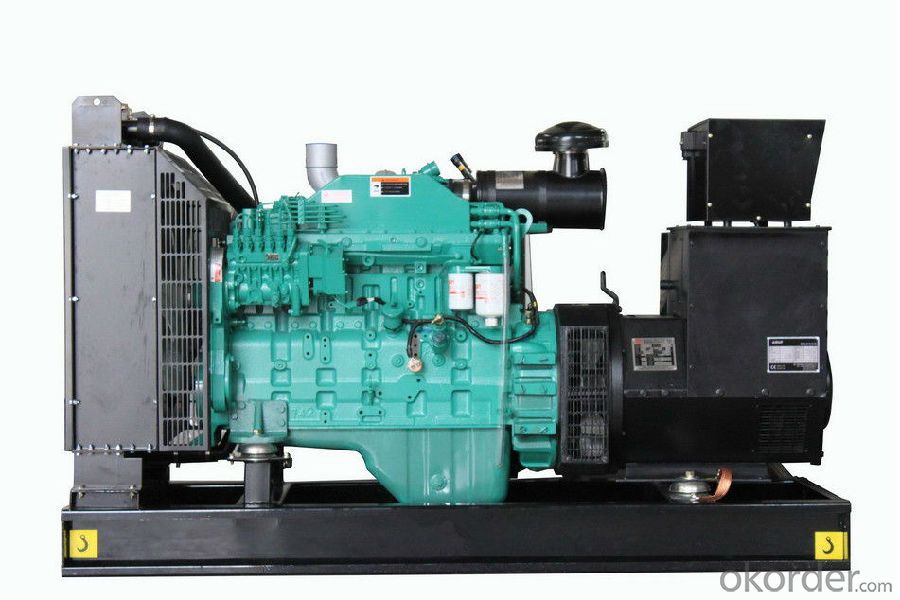

Soundproof Genset Diesel Generator , 35kw To 680kw Cummins Generator

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1500 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Detail:

1.Cummins Water Cooled Diesel Engine :4BTA3.9-G2,6BTA5.9-G2,KTA19-G3

2.Machinery or electronic governing

3.Original Stamford AC Alternator:UCI224E ,UCI274D,UCI274H

4.smartgen,Deepsea Control Panel with ats

Specifications:

Genset Model | Prime Power | Standby Power | Engine | Fuel Consumption | Cylinder No. | Displacement | Bore X Stroke | ||

KW | KVA | KW | KVA | (g/kwh) | (L ) | (mm) | |||

GNRC30 | 20 | 25 | 24 | 30 | 4B3.9-G | ≤229 | 4 | 3.9 | 102*120 |

GNRC35 | 24 | 30 | 28 | 35 | 4BT3.9-G2 | ≤214 | 4 | 3.9 | 102*120 |

GNRC56 | 40 | 50 | 45 | 56 | 4BTA3.9-G2 | ≤215 | 4 | 3.92 | 102*120 |

GNRC63 | 45 | 56 | 50 | 63 | 4BTA3.9-G2 | ≤215 | 4 | 3.92 | 102*120 |

GNRC70 | 50 | 63 | 56 | 70 | 6BT5.9G2 | ≤215 | 6 | 5.88 | 102*120 |

GNRC106 | 78 | 98 | 85 | 106 | 6BT5.9G2 | ≤215 | 6 | 5.88 | 102*120 |

GNRC125 | 90 | 113 | 100 | 125 | 6BT5.9G2 | ≤215 | 6 | 5.88 | 102*120 |

GNRC150 | 104 | 130 | 120 | 150 | 6BT5.9G2 | ≤215 | 6 | 5.88 | 102*120 |

GNRC165 | 120 | 150 | 132 | 165 | 6CTA8.3-G2 | ≤210 | 6 | 8.3 | 114*135 |

GNRC200 | 140 | 175 | 160 | 200 | 6CTA8.3-G2 | ≤210 | 6 | 8.3 | 114*135 |

GNRC225 | 160 | 200 | 180 | 225 | 6CTAA8.3-G2 | ≤210 | 6 | 8.3 | 114*135 |

GNRC275 | 200 | 250 | 220 | 275 | 6LTAA8.9-G2 | ≤210 | 6 | 8.3 | 114*135 |

GNRC313 | 220 | 275 | 250 | 313 | NTA855-G1A | ≤206 | 6 | 14 | 140*152 |

GNRC350 | 250 | 313 | 275 | 350 | NTA855-G2 | ≤207 | 6 | 14 | 140*152 |

GNRC400 | 280 | 350 | 310 | 400 | NTA855-G4 | ≤208 | 6 | 14 | 140*152 |

GNRC413 | 300 | 375 | 330 | 413 | NTAA855-G7 | ≤206 | 6 | 14 | 140*152 |

GNRC450 | 320 | 400 | 360 | 450 | NTAA855-G7A | ≤206 | 6 | 14 | 140*152 |

GNRC500 | 360 | 450 | 400 | 500 | KTA19-G3 | ≤203 | 6 | 18.9 | 159*159 |

GNRC550 | 400 | 500 | 440 | 550 | KTA19-G4 | ≤203 | 6 | 18.9 | 159*159 |

GNRC605 | 440 | 550 | 484 | 605 | KTAA19-G6 | ≤204 | 6 | 18.9 | 159*159 |

GNRC625 | 450 | 563 | 500 | 625 | KTAA19-G7 | ≤204 | 6 | 18.9 | 159*159 |

GNRC700 | 500 | 625 | 560 | 700 | KTA38-G | ≤206 | 12 | 37.8 | 159*159 |

GNRC712 | 520 | 650 | 570 | 712 | QSK19-G3 | ≤206 | 6 | 19 | 159*159 |

GNRC800 | 580 | 720 | 640 | 800 | KTA38-GA | ≤209 | 12 | 37.8 | 159*159 |

GNRC825 | 600 | 750 | 660 | 825 | KTA38-G2 | ≤210 | 12 | 37.8 | 159*159 |

GNRC888 | 640 | 800 | 710 | 888 | KTA38-G2B | ≤210 | 12 | 37.8 | 159*159 |

GNRC975 | 720 | 900 | 780 | 975 | KTA38-G2A | ≤210 | 12 | 37.8 | 159*159 |

GNRC1075 | 800 | 1000 | 860 | 1075 | KTA38-G5 | ≤202 | 12 | 37.8 | 159*159 |

GNRC1375 | 1000 | 1250 | 1100 | 1375 | KTA50-G3 | ≤215 | 16 | 50.3 | 159*159 |

GNRC1375 | 1100 | 1375 | 1310 | 1650 | KTA50-G8 | ≤215 | 16 | 50.3 | 159*159 |

GNRC1650 | 1200 | 1500 | 1340 | 1675 | KTA50-GS8 | ≤215 | 16 | 50.3 | 159*159 |

GNRC1675 | 1350 | 1688 | 1500 | 1875 | QSK60-G3 | ≤215 | 16 | 60 | 159*159 |

GNRC1875 | 1500 | 1875 | 1650 | 2063 | QSK60-G3 | ≤215 | 16 | 60 | 159*190 |

GNRC2063 | 1600 | 2000 | 1800 | 2250 | QSK60-G4 | ≤215 | 16 | 60 | 159*190 |

Genset Features:

1. Genuine Commins industrial diesel engine

2. Radiator 40°C max, fans are driven by belt, with safety guard

3. Genuine stamford. Leroy somer, marathonm, engga alternator

4. Choice of manual/auto and AMF control panels and protection systems

5. Digital auto-start panel

6. Anti Vibration Suspension Absorber

7. Dry type air filter, fuel filter, oil filter

8. 10-hour operation base tank

9.Mould case circuit breaker

10. 24V DC start motor and storage battery

11. 24V charge alternator

12. 24V batteries, rack and cable

13. Rippl;e flex echaust pipe, exhaust siphon, flange, and muffler

14. Comply with ISO and CE standards

15. All generator sets are gone through rigorous testing before beging released to the market place, including 50% load, 75% load, 100% load and all protection function(over speed stop, high water temperature, low oil pressure, battery charging fail, emergency stop)

Engine Features:

1. Genuine Cummins industrial diesel engine

2. Multi-cylinder in-line or veer engine, 4-stroke, direct injection

3. Naturally aspirated, turbocharged, water cooled or turbocharged with air intercooler

4. Machinery or electronic governing

5. Fuel injection pump

6. Electric motor starting system

7. Forged steel crankshaft, cast iron cylinder and replaceable wet type cylinder liner

8. Low discharge, and low fuel consumption

9. Installed conveniently and maintain easily

Alternator Features:

1. World famous brand AC alternator: Leroy Somer, Stamford, Marathon, ENGGA

2. Brushless, 4 poles, rotation magnet

3. IP21-23(NEMA1) enclose is standard for all industrial alternators

4. H class insulation system

5. AVR self-regulated, voltage regulation rate: ≤±1%

6. Simple installation and maintenance with easy access to terminals, rotating diodes and coupling bolts

7. Wide range of flange adaptors and single bearing disc coupling

8. Radio interference restraining accords with the stipulation of VDE0875-N and ISO8528

9. Moisture proof, sand-proof, dustproof, salt-proof and vibration-proof

Digital Control panel

Controller Brand: Smartgen, Deepsea,ComAp

Control Panel: English interface,LED screen and touch buttons.

- Q:What is the difference between explosion-proof motor and ordinary motor

- The cooling fan at the tail end of the motor is used to keep the blades of the wind from the wind shield, and the outside of the wind blade is larger than the guide, and the blades are made of plastic. Why the appearance of explosion proof machine is so unflattering: because the front and rear cover is fixed by the hollow bolt and the socket is deep, it makes the ends appear not round and round. The junction box with a tube is a weird and complex structure, unlike a normal motor connection box. See the roundness and concise appearance that is used to general electric motor, look again the explosion-proof electric machine that has the Angle of a kind of strange Angle also can feel not good-looking! Hahaha, deep-sea diving cap, space cap, gas mask, dust respirator... People put it on his head and mouth, isn't it also worse than pig's mouth, is the functional structure, they have decided they ugly external shape, is helpless!

- Q:The difference between PWM and general motors

- PWM motor is frequency conversion motor, that is, the inverter output waveform is not filtering after PWM wave, ordinary motor generally as a standard, usually sinusoidal waveform, if use frequency converter drive, also need to add after the inverter output filter circuit, or general motors can not stand, fever is serious, but also is frequency conversion motor PWM motor is ok.

- Q:How do you differentiate the converter motor from the general motors?

- Variable frequency motor and the common one of the biggest difference is the fan cooling way, general motors was the cold, the fan on the motor shaft, changes with the rotational speed of the motor, so the ordinary motor at low frequency heat dissipation is not ideal. Frequency conversion motor cooling fan is behind the motor equipped with a cooling fan, need an external power, the fan will not be affected by the speed of the motor, is a strong refrigeration.

- Q:How do ordinary motors achieve precise positioning

- Ordinary motors can be accurately positioned through a series of circuits. Specific as follows: In action slider side low add a micro switch, micro switch control an intermediate relay, in the middle of the normally closed contact is broken the power of the motor, and at the same time delay relay through 3 s, the use of time relay normally open point back to the motor power supply. The highest point also can add a microdynamic switch the principle is the same! This completes the basic positioning control circuit and the lowest cost.

- Q:The difference between ordinary motor and permanent magnet motor

- The permanent magnet motor is the synchronous motor, which has a permanent magnet, which interacts with the magnetic field generated by the external power source and produces torque.

- Q:What is the difference between a general motor and a high-speed motor?

- The rotational inertia of high speed motor is generally small, so the long type of motor is more.

- Q:The difference between brushless dc motor and plain dc motor, where is its advantage

- Brushless dc motor and brushless dc motor is the difference between ordinary is as follows: 1, the brushless dc motor with integrated drive circuit commutation, ordinary brushless dc motor with brush and commutator with the reversing, keep the continuous rotation of the motors. The winding of brushless dc motor is the stator, the magnet is the rotor, and the common windings are the rotor, the electromagnet is the stator. The non-brush dc motor USES rare earth permanent magnet (nd-ti-boron permanent magnet) to achieve greater power and efficiency, and ordinary brush dc motor USES ferrite permanent magnet. The non-brushless dc motor is usually multi-groove, 6 slots, 9 slots, 12 slots, 24 slots, etc., the average brush dc motor has fewer slots, 3 slots, 5 slots, 7 slots etc. The company has shenzhen constant drive motor co., LTD.

- Q:What is the difference between a single phase motor and a two-phase machine?

- You mean should be the difference between the single-phase motor and three-phase motor, the difference between them is to use the power supply is different, single-phase motor using household electricity, three-phase industrial three-phase electric motor.

- Q:What is the difference between an energy-saving motor and a general motor

- The high efficiency energy-saving motor adopts new motor design, new technology and new materials, and improves the output efficiency by reducing the loss of electromagnetic energy, heat energy and mechanical energy. Compared with ordinary motor, the efficiency of using high-efficiency motor is obvious, and the efficiency can be increased by an average of 4%. The weight is basically the same. High efficiency energy-saving motor is the general motors with high efficiency.

- Q:How big a car is it to replace the engine, how big a generator is needed to power the car, can the car be able to hold down, can also install other things

- At least thirty kilowatts. The ford motor car EV1 USES a 42kw three-phase induction motor.I hope my answer will help you

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Soundproof Genset Diesel Generator , 35kw To 680kw Cummins Generator

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1500 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords