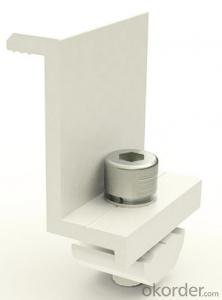

Solar Power System Components, Framed Solar Panel Clamps, Solar Mounting System Adjustable End Clamps

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Solar Power System Components, Framed Solar Panel Clamps, Solar Mounting System Adjustable End Clamps

Specifications

Solar Mounting System End Clamps:1)ISO 9001,AS/NZS 1170&TUV certified

2)Fit all kinds of panels

3)Easy installation

- Q:Can a solar mounting system be used in areas with solar incentives for warehouses?

- Yes, a solar mounting system can be used in areas with solar incentives for warehouses. In fact, it is highly recommended to install solar panels in warehouses to take advantage of the available incentives and maximize the potential for energy savings.

- Q:Can a solar mounting system be used in areas with solar incentives for train stations?

- Yes, a solar mounting system can definitely be used in areas with solar incentives for train stations. These incentives are designed to encourage the adoption of renewable energy sources like solar power. By installing a solar mounting system at train stations, not only can these incentives be capitalized upon, but also the stations can generate clean and sustainable electricity, reducing their reliance on traditional power sources and contributing to a greener transportation infrastructure.

- Q:Can a solar mounting system be used on residential buildings?

- Yes, a solar mounting system can definitely be used on residential buildings. In fact, many homeowners choose to install solar panels on their roofs using mounting systems designed specifically for residential applications. These systems are designed to securely attach the solar panels to the roof while optimizing sun exposure and maximizing energy generation.

- Q:Can a solar mounting system be used in areas with limited access to solar webinars?

- Yes, a solar mounting system can still be used in areas with limited access to solar webinars. While webinars can provide valuable information and training, there are other resources available such as instructional manuals, technical support, and on-site assistance that can help in understanding and implementing a solar mounting system in areas without easy access to webinars.

- Q:Can a solar mounting system be used in areas with limited access to solar podcasts?

- Yes, a solar mounting system can be used in areas with limited access to solar podcasts. The functionality and effectiveness of a solar mounting system is not dependent on access to solar podcasts. The system's performance relies solely on the availability of sunlight, which can be harnessed for generating solar energy regardless of access to podcasts or any other form of media.

- Q:Can a solar mounting system be used on carports?

- Yes, a solar mounting system can be used on carports. In fact, carports are an ideal location for installing solar panels as they provide ample space and can also provide shade and protection for vehicles while generating clean energy.

- Q:Can a solar mounting system be installed on a rooftop with a TPO roof?

- Yes, a solar mounting system can be installed on a rooftop with a TPO (Thermoplastic Olefin) roof. TPO roofs are commonly used in commercial and residential buildings and are compatible with solar panel installations. However, it is important to consult with a professional installer to ensure proper installation techniques are followed to maintain the integrity of the TPO roof and minimize any potential damage.

- Q:Can a solar mounting system be used on flat ground surfaces?

- Yes, a solar mounting system can be used on flat ground surfaces. In fact, ground-mounted solar systems are commonly installed on flat or gently sloping terrains to maximize energy production and ease installation.

- Q:Can a solar mounting system withstand extreme weather conditions?

- Yes, a solar mounting system is designed to withstand extreme weather conditions. It is built with durable materials and engineered to withstand high winds, heavy snow loads, and other severe weather events. Additionally, proper installation and maintenance play a crucial role in ensuring the system's resilience to harsh weather conditions.

- Q:Can a solar mounting system be used with solar-powered security systems?

- Yes, a solar mounting system can be used with solar-powered security systems. The solar mounting system is designed to securely hold and position solar panels, which generate the power for the solar-powered security systems. By harnessing the sun's energy, the solar mounting system ensures an efficient and reliable power source for the security systems, making them independent of the electrical grid.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Solar Power System Components, Framed Solar Panel Clamps, Solar Mounting System Adjustable End Clamps

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords