SOLAR PANEL POLY FOR 250W,SOLAR PANEL IN CHINA WITH GOOD QUALITY

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2600 watt

- Supply Capability:

- 26000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Features of our products:

• High conversion efficiency mono/poly-crystalline amorphous silicon solar cells

• Modules incorporate high performance bypass diodes to minimize the power drop caused by shading

• High transmittance, low-iron tempered glass

Structure of Solar Module Description

Solar panel refers either to a solar hot water panel, a common type of a solar thermal collector, or to one or more solar photovoltaics (PV) modules, electrically connected and mounted on a supporting structure.

A PV module is a packaged, connected assembly of typically 6×10 solar cells. Solar PV panels constitute the solar array of a photovoltaic systemthat generates and supplies solar electricity in commercial and residential applications. Each module is rated by its DC output power under standard test conditions, and typically ranges from 100 to 320 watts. The efficiency of a module determines the area of a module given the same rated output – an 8% efficient 230 watt module will have twice the area of a 16% efficient 230 watt module. There are a few solar panels available that are exceeding 19% efficiency. A single solar module can produce only a limited amount of power; most installations contain multiple modules. A photovoltaic system typically includes a panel or an array of solar modules, an inverter, and sometimes a battery and/or solar tracker and interconnection wiring.

Polycrystalline Silicon Solar Modules 48Cell-195W Specification

ELECTRICAL PERFORMANCE | |||

Power output | P max | W | 195 |

Power output tolerances | ΔP max | W | 0/+5 |

Module effi ciency | η m | % | 14.7 |

Voltage at Pmax | V mpp | V | 23.7 |

Current at Pmax | I mpp | A | 8.03 |

Open-circuit voltage | V oc | V | 30.1 |

Short-circuit current | I sc | A | 8.65 |

Product Description:

This installation Manual contains essential information for the electrical and mechanical installation that your must know before installing CUSTOMER PV modules. This also contains safety information you need to be familiar with .

CUSTOMER does not assume responsibility and expressly disclaims liability for loss, damage, or expense arising out of in anyway connected with installation, operation, use or maintenance of the PV modules. No responsibility is assumed by CUSTOMER for any infringement of patents or other rights of third parties that may result from use of PV module.

Solar panel working process

In addition to being the ultimate source of all life on earth, the sun is an infinitely renewable, completely pollution-free source of electricity. Instead of burning fossil fuels dug up from the ground in a big power plant – a very 19th century, industrial age approach, when you think about it – solar panels convert sunlight directly into electricity, with no harmful emissions.

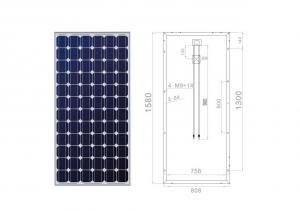

Specification of Solar Monocrystalline Series

- Optimal permutation on solar cells to keep enough heat diffusion, decreases hot spot effect.

- High quality and anti-ageing EVA, weather resistance backside raw materials assure reliable solar panels.

- Passed 5400Pa mechanical loads testing by UL, can withstand bad and high mechanical load working environment.

- With good sealed performance, moisture resistant, aging resistance, high/low temperature resistant, the inner terminals of our junction box owns good electrical performance transmission. Bypass diodes used can avoide hot spot effect and damages to panels. Output cables and mating connectors are safe and reliable for installation application. Adopt weather resistance, sealed, good sticky silica gel when assembling.

- Strict quality inspection on each procedure and 100% electrical performance test to meet power requirements.

- 0~+3% power tolerance.

- classification for all the panels in order to improve the integral performance of system and solar panel life span.

- TUV、UL、MCS、CE、ROHS、Golden Sun certified

- Underwriting of 25years output power warranty by The People's Insurance Company of China.

- Q:I was watching an idiot abroad, and I saw a family that lived in tent like huts, with no plumbing. And they had a solar panel, now if they can afford it, I know I can. Where do you get cheap ones?

- Guide okorder /

- Q:What is the difference between solar panels and light panels?

- The highest conversion efficiency in the laboratory is 24.7%, and the efficiency of the scale is 16%. Polysilicon conversion rate of 14% -15%. Amorphous silicon conversion rate of 12%. Silicon film conversion rate of 9%. Silicon solar cell is the main raw material of silicon, silicon is an extremely rich element of the earth, almost everywhere there are silicon, can be said to be inexhaustible, with silicon to create solar cells, raw materials can be described as no shortage.

- Q:I thinking of buying a few solar panels, can anyone who had bought solar panels or sells them give me a price for them. I dot wanna over spend on them...

- Hello, Solar panels range from 200 to 400, depends on where you get them from. I got a good setup from iron edison which came delivered. I bought a 00 watt solar panel for $225, upon opening the delivered package, it was a high quality, clean cut panel that really obliged me to power it with a high quality battery. So I searched all over the place for HIGH quality solar batteries/asked many people, and came across VMAX solar batteries. These are top of the line, they have the best lifespan out of all the batteries I've tried and have been buying them from Bargainshore for years now. I recently bought more panels and used the the same setup, couldn't be happier! Goodluck!

- Q:Just curious.

- Since you said does instead of do I think it would be fruitless trying to explain it...

- Q:Can solar panels be installed on a warehouse or storage facility?

- Yes, solar panels can be installed on a warehouse or storage facility. In fact, warehouses and storage facilities are often ideal locations for solar panel installations due to their large, flat rooftops and ample space for arrays. Installing solar panels can help these facilities reduce their electricity bills, lower their carbon footprint, and even generate additional income through various incentive programs.

- Q:If a solar panel is a .5kW system, what length of time is it putting out that much power? Every hour?

- Power = work done/time taken In other words, Watts=Joules/second. In this respect, power is a little like speed (m/s). Your question is looking at a car with a 50mph top speed, and asking how long is it going that fast? The solar panel will produce .5KW for as long as you require it. Enough to boil a kettle, run a modest electric heater etc,

- Q:Can solar panels work at night?

- No, solar panels do not work at night as they rely on sunlight to generate electricity.

- Q:Can solar panels be installed on rooftop gardens or green roofs?

- Yes, solar panels can be installed on rooftop gardens or green roofs. In fact, these locations can provide an ideal setting for solar panel installation as they often receive ample sunlight due to their elevated position and minimal shading. Additionally, the vegetation and greenery on these rooftops can help with temperature regulation and improve the overall efficiency of the solar panels.

- Q:Can solar panels be connected directly to motor?

- The sun is irradiated on the semiconductor p-n junction to form a new hole-electron pair. Under the action of the p-n junction electric field, the holes flow from the n region to the p region. The electrons flow from the p region to the n region, and the current is formed after the circuit is turned on.

- Q:I am planning to buy some solar panels for my cabin and i want to be able to store the electricity. what kind of batteries should i get? i will be running simple things like a tv and radio. where can i buy these batteries? where should i look for the best batteries?

- Deep cycle, Golf Cart Batteries. You can get them at a battery store.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

SOLAR PANEL POLY FOR 250W,SOLAR PANEL IN CHINA WITH GOOD QUALITY

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2600 watt

- Supply Capability:

- 26000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products