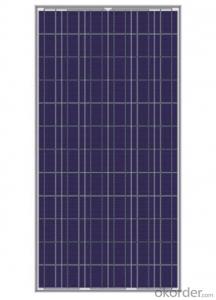

Solar Panel & Module with High Quality in 150W

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Place of Origin: | Zhejiang, China (Mainland) | Brand Name: | CNBM | Model Number: | OL-150-36M |

| Material: | Monocrystalline Silicon | Size: | 1480*680*35mm | Number of Cells: | 36 |

| Max. Power: | 150 | certification: | CE ROHS ISO | frame: | aluminium frame |

| poly or mono: | mono | cell color: | black | cell array: | 4*9 |

| junction box: | junction box with MC4 connector | voltage: | Vmp:18v,for 12V battery charging | main market: | Asia EU Africa |

Packaging & Delivery

| Packaging Details: | inner carton and outer carton with one apron between 2 pcs of solar panel, cartons connected together in pallet with plastic bags around them, put several wooden cases under the pallet |

| Delivery Detail: | within 20 days |

Product Description

Specifications

25 years warranty

Class-A Grade quality

EL test of each panel

Produced under automatic machines which bought from Germany

- Q:how to build a solar panel

- Can you show us how to build a solar panel ?

- Q:Can solar panels be installed on electric fences?

- Yes, solar panels can be installed on electric fences. They provide a sustainable and cost-effective way to power the electric fencing system, eliminating the need for a direct electrical connection or reliance on traditional power sources. Solar panels can easily be integrated into the design of an electric fence, enabling it to operate efficiently and independently in remote or off-grid areas.

- Q:Are the solar panels on the roof just a gimik to get all the tree huggers to buy it, or are they actually a good, efficent design?

- The solar panels run the fan to remove hot air from the car. They do about the same amount of cooling that cracking the windows and using a heatshield over the windshield--that is they keep the interior of the car about the same as the exterior without draining the 2V battery. One problem I have with the solar panels is that they come with a moonroof. The other problem I have with them is that to get them you have to give up the additional safety features because Toyota won't put both the high tech safety features and the solar panels on the same car. So is it a good design? Well, nothing with a sun/moonroof is a good design IMHO, but that's the power of advertising for you. In that it runs a fan without draining the 2V battery, yes that part's good. Having to give up the high tech safety features to get it makes it a non-starter for me (and I live where it gets plenty hot so I could really use the fan).

- Q:Has anyone had any experience building their own solar panels for home use? I have seen on the news lately that people are utilizing solar panels to power their hot water heaters to save on their power bill.

- a solar hot water heater is not a solar panel that makes electricity that runs your hot water heater.....it is merely a long tube or pipe, bent back on itself so there,s, say 00 feet in a 2foot by 4 foot space; it's in a framework and under a sheet of glass or plastic; You put out in the sun and it captures heat.....ever notice how hot the water is coming out a garden hose that has been left out in the sun in summer? Same idea.. we have used them here in the islands for years and they work great. Even up north, a solar hot water heater that preheats the water before it goes to a traditional water heater should work fine.

- Q:Well, I am looking for a cheap way on building a solar panel, instead of buying by the manufacturing stores. I would like to stay in the budget up to ,000 dollars. I want to have Solar Energy for my house because the sun is always shining. Is there a way I can make the Light power some of my house? What would I need? How much time would it take?Where can I get the items I need?

- DIY okorder

- Q:Do solar panels produce noise?

- No, solar panels do not produce noise as they do not have any moving parts.

- Q:Are there any fire hazards associated with solar panels?

- Yes, there are potential fire hazards associated with solar panels. Although solar panels themselves do not typically catch fire, electrical malfunctions or faults in the wiring, inverters, or connectors can lead to overheating and fire. Additionally, if a fire breaks out in the surrounding area, solar panels can hinder firefighting efforts by creating potential electrical hazards and obstructing access to the roof. Therefore, proper installation, regular maintenance, and compliance with fire safety regulations are crucial in mitigating these risks and ensuring the safe operation of solar panel systems.

- Q:Around this time here in Georgia we will begin to get some big storms with high winds. I have a solar panel on a mount that isn't all that sturdy and could be knocked over with any winds pretty much above 5mph. I can't put anything in the ground to do this. I used to have it mounted to the roof of a playground for the most sunlight, but because of the angle of the sun and the tree leaves, I have to have it on a quot;portablemount so I can move it throughout the day, and I can tell you one thing is certain, and that's that it isn't the most sturdy thing ever. I'll have it a little better next weekend but it'll still be able to easily blow in the wind. Should I just hang the panel along the wall during a storm then reconnect it to its base once it's over?I'm pretty good with wood, so any wood creations to help out with the thing would greatly help. Just please keep it on a low budget.

- You have to make the decision weather you want it portable or stationary. If you want stationary I would make some good brackets for them / search for cheap ones on OKorder. I'd have to see them to be able to offer any better suggestions. It's always hard to decide so you'll have to take notes and do research.

- Q:Thanks

- Initial cost , space occupied AND DAILY CYCLE (unless through a battery) are the only disadvantages. REST ARE ALL ADVANTAGES

- Q:Can solar panels be used in areas with high levels of shade?

- Solar panels can still be used in areas with high levels of shade, but they may not be as efficient as in areas with direct sunlight. The shade reduces the amount of sunlight reaching the panels, which decreases their overall performance. However, with advancements in technology, some panels are designed to handle shade better than others. Additionally, proper installation and placement of the panels can help optimize their performance even in shaded areas.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Solar Panel & Module with High Quality in 150W

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords