SOLAR PANEL 260w,SOLAR PANEL FOR SALE,SOLAR PANEL PRICE FOR HIGH EFFICIENCY

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2600 watt

- Supply Capability:

- 26000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

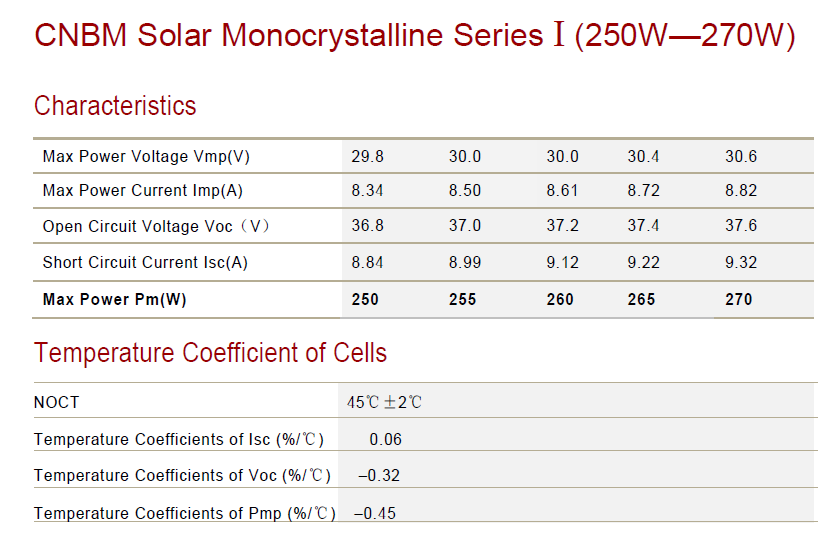

Rated maximum power (Pmax) 260W

Open circuit voltage (vOC) 37.30

Short circuit current (Isc) 8.78

Maximum power voltage (Vmp) 30.10

Maximum power current (Imp) 8.31

Cell efficiency (%) 17.50%

Max system voltage (VDC) 1000V DC

Temperature coefficient of Vm -0.241%/K

Temperature coefficient of Im +0.033%/k

Temperature coefficient of power -0.37%/K

Maximum Series Fuse Rating 15A

Solar cell and configuratiou 60pcs(6*10)in series,156*156mm monocrystalline

Junction box IP65,1000VDC,TUV certified;6 pcs Schottky By-pass diodes

Cable type & CONNECTOR 4m㎡,TUV certificated,0.9m length;MC4

Encapsulation low iron tempered glass,3.2mm thickness,light transmission above 91%;TPT and fast cure EVA

Farame clear anodized aluminum alloy,50/45mm thickness,silver

Dimension (l*W*H) 1640*990*50mm/45mm

Weight 20KG/19KG

Heavy mechanical load salient features 540Pa (ACCORDING TO ICE61215)

Hail impact test lce ball dianeter 25mm,23m/s

Operating temperature -40℃~+85 ℃

Standard test conditions: STC:AM=1.5,1000W/m2,cells temperature 25℃

Power tolerance:±3% (can be provided 0~±3%)

GENERAL INFORMATION

The installation of PV modules requires a great degree of skill and should only be performed by a qualified licensed professional, including licensed contractors and licensed electricians. Please be aware that there is a serious risk of various types of injury occurring during the installation including the risk of electric shock. All CUSTOMER modules are equipped with a permanently attached junction terminal box that will accept variety of wiring applications or with a special cable assembly for ease of installation, and they do not require assembly.

Solar panel working process

In addition to being the ultimate source of all life on earth, the sun is an infinitely renewable, completely pollution-free source of electricity. Instead of burning fossil fuels dug up from the ground in a big power plant – a very 19th century, industrial age approach, when you think about it – solar panels convert sunlight directly into electricity, with no harmful emissions.

The basic unit of a solar panel is a solar cell, which usually consists of one or two layers of silicon-based semiconductor wafers. When struck by the photons in sunlight, the solar cell generates an electrical charge due to the "photovoltaic effect" – which is a pretty good name, since it produces voltage from photons. The flow of these electrons moves in a steady electrical current from one side of the cell to the other.

- Q:Can solar panels be installed on bridges or highways?

- Yes, solar panels can be installed on bridges or highways. In fact, there are several projects around the world where solar panels have been installed on bridges and highway infrastructure. These installations not only generate clean energy but also utilize underutilized spaces, contributing to sustainable and efficient use of resources.

- Q:Do solar panels require a battery for storage?

- No, solar panels do not require a battery for storage. Solar panels generate electricity directly from the sunlight and can be connected to the electrical grid to supply power during the day. However, using a battery with solar panels allows for energy storage, ensuring a continuous power supply even when the sun is not shining or during power outages.

- Q:I have a 2 volt deep cylce Everstart battery with 845 cranking amps, and a Grape Solar GS-S-250-Fab5 250-Watt Monocrystalline Solar Panel . I use them to power a 48Flat screen TV, a Roku, my 65 watt consuming MacBook Pro, and a 65 watt Fan.I know from previous experience that just the battery, an inverter, and the fan, that the fan will blow for 0 hours straight.Should I really be concerned with a Charge Controller?

- Should I really be concerned with a Charge Controller? Yes. The main purpose of the charge controller is to protect the battery from over charging. Over charging reduces battery life. And spending extra money for a MPPT type controller will get more more useable power out of your solar panel. Would another battery of the same magnitude be helpful in preventing an accident? How much storage capacity does your current battery have (measured in kWH)? A ~$20 Kill-a-Watt meter would take a lot of uncertainty out of how much power you actually use. Even deep cycle batteries suffer reduced battery life from deep discharges. The battery sounds too small for the loads you describe so I would think you would want more. ---------------------------------------... After reading the other answer In a nutshell, with your small 2 volt starting battery, 24 volt panel and a mix of unknown loads, (which is correct), I thought I would elaborate. I had not considered the possibility that you bought a 24 volt panel for your 2 volt battery. Hooking the panel you bought directly to the current battery is a horrible idea. I you were lucky it would just cook the battery in a short period of time. You basically bought the wrong type of panel for a 2 volt system. I assume that there are no controllers on the the market for this situation. If that's the case, I don't know of any good way match the 24v panel to the 2 volt battery.

- Q:is a wind turbine better than solar panels

- solar water heater and solar power system.

- Q:how much energy or electricity a solar panel produces?

- First, okorder /... Second, as a general rule of thumb, you can generate at most 00 watts of power (.Kwh) per 2 square feet of roof space. I have had to revise my own estimates after building a solar array in my yard using high grade solar panels. Solar panels do not put out their peak rating all the time. NOTE: I am not paid nor given any compensation by solar interests.

- Q:Can solar panels be installed on a garage or carport?

- Yes, solar panels can be installed on a garage or carport. These structures often provide ample space and a suitable angle for solar panel installation, allowing homeowners to generate clean and renewable energy while utilizing the available space efficiently. Installing solar panels on a garage or carport can also provide additional benefits such as shade for vehicles, reduced utility bills, and the opportunity to contribute to a greener environment.

- Q:what parts and tool do i need to build and connect a solar electric panel to my home

- Solar energy is very expensive. Or I should say, solar panels are expensive, because once you install them the power is free. A typical residential solar power system that supplies around a kilowatt of power at best conditions (noon, sunny day) will cost about $0,000. This includes the solar panel, the inverter (converts DC into AC), the cabling, but not installation (that would probably run you another $2000). One kilowatt is not that much electricity. It would run one microwave oven, or one hair dryer, or 0 light bulbs, and nothing else. Most houses use 3 times that at peak hours. So you would still likely get some power off the grid at peak time, and other times you can sell it back to make a little money. The good news is that solar panels are getting cheaper. They are around $5 per watt now, and are projected to drop to half that in the next decade. At some point, it will reach the sweet spot that makes solar an attractive alternative to grid power and more people will jump on board. There are some tax incentives too, but more would certainly help.

- Q:I need a 2v (500-800ma) solar panel that in can fit on a 24inx4in flat surface. Where can i get one this size and with this power?

- Build okorder /

- Q:Can solar panels be used in deserts?

- Yes, solar panels can definitely be used in deserts. In fact, deserts are considered ideal locations for solar power generation due to their high solar irradiance and vast open spaces. The availability of ample sunlight allows solar panels to efficiently convert sunlight into electricity. Additionally, deserts often have less cloud cover and atmospheric interference, resulting in more consistent and predictable solar energy production.

- Q:Can solar panels be used to power a swimming pool?

- Yes, solar panels can be used to power a swimming pool. Solar panels can convert sunlight into electricity, which can then be used to power various devices, including swimming pool pumps, heaters, and lights. By utilizing solar energy, pool owners can reduce their reliance on traditional electricity sources and lower their overall energy costs.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

SOLAR PANEL 260w,SOLAR PANEL FOR SALE,SOLAR PANEL PRICE FOR HIGH EFFICIENCY

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2600 watt

- Supply Capability:

- 26000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords