Solar Cells A Grade and B Grade 3BB and 4BB with High Efficiency 17.6%

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 watt

- Supply Capability:

- 100000000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

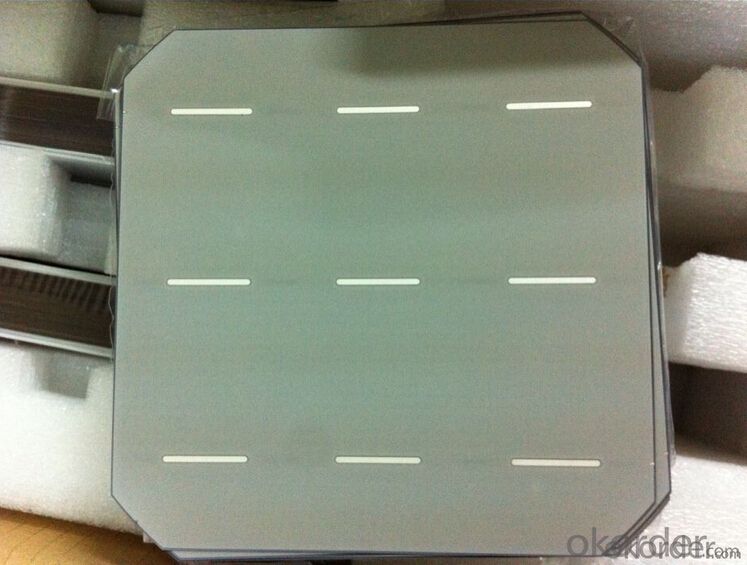

1.Product Description:

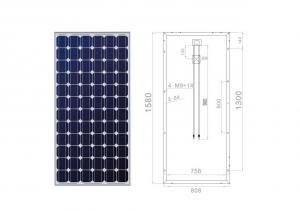

Specifications of Poly Solar Cells

Dimension | 156mm X 156 mm ±0.5mm |

Wafer Thickness | 200um ±30um |

Front(-) | Four 1.1mm wide bus bars(silver) with distance 39mm, Acid texturized surface with blue silicon nitride AR coating. |

Back(+) | 2.4mm wide silver/aluminum soldering pads, aluminum back surface field. |

Temperature Coefficient of Poly Cells

Voc.Temp .coef.%/K | -0.351%/K |

Isc.Temp .coef.%/K | +0.035%/K |

Pm.Temp. coef.%/K | -0.47%/K |

Electrical Characteristic of Poly Cells

Efficiency code | 1720 | 1740 | 1760 | 1780 | 1820 | 1840 | |

Efficiency (min) | (%) | 17.2 | 17.4 | 17.6 | 17.8 | 18.2 | 18.4 |

Pmax | (W) | 4.186 | 4.234 | 4.283 | 4.332 | 4.429 | 4.478 |

Voc | (V) | 0.631 | 0.632 | 0.634 | 0.636 | 0.640 | 0.642 |

Isc | (A) | 8.446 | 8.485 | 8.523 | 8.573 | 8.660 | 8.700 |

Vmp | (V) | 0.525 | 0.527 | 0.529 | 0.531 | 0.535 | 0.537 |

Imp | (A) | 7.973 | 8.035 | 8.097 | 8.160 | 8.280 | 8.340 |

2.Advantages of Poly Solar Cells

1). Tire-1 Solar Cells’ Manufacturer Quality Guarantee. With a complete and sophisticated quality government system, our Quality Management have arrived world’s leading place. Customer can receive Tire-1 Cells Maker’s Quality Standard Products.

2). Trusted Warranty. We can supply trusted after-sales service to our customer. If our cells are found not in conformity to the specification of manufacturer, or should the inspected quantity found in shortage, or should the packing found damaged, the buyer has the right to claim to the seller. The claim, if any, should be presented to seller within 30 days after cargo's arrival date to the port, together with related inspection report and photos issued and provided by a reputable independent surveyor such as SGS.

3). World’s Leading Manufacturer Equipment. We imported the newest and leading production equipment from abroad. Advanced equipment can guarantee the stable quality of cells. Auto production line can also save labor cost which will further cut our production cost.

4). Bulk supply: With the production capacity of 500MW, we can produce large quantity every month. This can satisfy most customer requirement.

3.Usage and Applications of Poly Cells

Solar cells are often electrically connected and encapsulated as a module.

Photovoltaic modules often have a sheet of glass on the front (sun up) side, allowing light to pass while protecting the semiconductor wafers from abrasion and impact due to wind-driven debris, rain, hail, etc. Solar cells are also usually connected in series in modules, creating an additive voltage.

Connecting cells in parallel will yield a higher current;our solar cells have passed IEC Certification.

With high quality and stable quality. Our Cells can greatly improve the performance of Solar Modules.

4.Pictures of Product

5.Packaging & Delivery of Poly Cells

Carton Box Package and Deliver by air. It should be noticed that it should be avoid water, sunshine and moist.

We have organized several common questions for our clients,may help you sincerely:

6.FAQ

1. What’s price per watt?

A: It’s depends on the quantity, delivery date and payment terms of the order. We can talk further about the detail price issue. Our products is high quality with lower price level.

2. Can you tell me the parameter of your solar cells?

We have different series of cells with different power output, both from c-si to a-si. Please take our specification sheet for your reference.

3. How do you pack your products?

We have rich experience on how to pack the panels to make sure the safety on shipment when it arrives at the destination.

4. Can you do OEM for us?

Yes, we can.

5. How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The perfect time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q:Can solar panels be installed on mobile homes?

- Yes, solar panels can be installed on mobile homes. In fact, mobile homes can be great candidates for solar panel installations due to their smaller size and affordability. Additionally, solar panels can help mobile homeowners save on electricity bills and reduce their carbon footprint.

- Q:Can solar panels be installed on factories or industrial buildings?

- Yes, solar panels can be installed on factories or industrial buildings. In fact, many industrial companies are increasingly installing solar panels on their roofs or open spaces to generate clean and renewable energy. This helps to reduce their dependence on fossil fuels, lower their energy costs, and contribute to a more sustainable and environmentally-friendly operation.

- Q:Can solar panels be installed on a historical building?

- Yes, solar panels can be installed on a historical building. However, it is important to consider the impact on the building's architectural integrity and historical significance. Careful planning and consultation with preservation experts may be necessary to ensure that the installation is done in a way that respects and preserves the building's historic value.

- Q:Is it really possible for me living in Denver to build and install and setup my own solar panel to help make electricity for my home?

- It's okorder / has something to say about various scams, including solar.

- Q:If not how do they give power to a house/a company?

- Solar panels can be connected to your household wiring with a piece of equipment called a grid tie inverter. You power company will probably require either an automatic or manual means for disconnecting your equipment from their grid in the event of a power outage or line maintainence. Homepower Magazine is an excellent source for information about solar and other alternative energy sources. A primer on the basics of solar electricity can be found using the first link below. You can download a free sample issue of the magazine using the second link below. The sample issue being offered changes occasionally. Don

- Q:I want to get definate instructions on how to make the components and convert my home to solar energy. I know I could hire some one to do this, but frankly I do not have the funds at my disposal to do it. I thought if I could find detailed instuctions I could slowly do it myself (with my husband's help). I have looked into loans for this purpose to no avail. Finding the information on the net could take forever! If anyone knows a site that would give me the information or even a hint on how to start? Any help will be appreciated, but if you have any good links to good information please share them with me..Thanks

- I doubt that you are going to want to learn how to dope your own silicon wafers, add contacts and laminate them into PV panels.? I also doubt that you're going to even want the various chemicals to make e.g. cadmium-based cells anywhere near your house (cadmium is a very toxic metal).? In other words, making your own solar panels is not an at-home project. You can buy solar panels based on cells of several different types.? A link to a Pricewatch-like website for current prices on solar panels is below.? Mounting panels to roofs or pole mounts, running conduit and wires, and installing battery banks and inverters are within the capabilities of skilled laypeople. More data at the links. Edit:? I am reporting all of Agua-Luna's cut-and-paste pieces as spam.? I encourage others to do likewise.

- Q:I am searching for producers or distributors of solar panels. Thanks!

- Grimcho..I'm going to give you a secret that no-one I know of has ever spoken of..Call Your local railroad maintenance yard and/or your local oil production company..I know your probably in another part of the world where this will not apply but here its like this.. BNSF changes out every 2-5 years their 00w 24v panels...they still have a good 5years of lifetime..Oil companies change them out on their well sites every 2 years 2x 60w 24v (actually they are 2 +2vdc grids series) now if your in Italy sorry this didn't work but if your in New Mexico ..they are in Santa FE...also they have way good batteries that are wet cell and run about 600$ each that they just dump many times on the guy for asking..try it....From the E....

- Q:Can solar panels be used for street lighting?

- Yes, solar panels can be used for street lighting. By harnessing the energy from the sun, solar panels can power street lights, eliminating the need for electricity from the grid and reducing carbon emissions. Solar-powered street lighting systems are increasingly being adopted as a sustainable and cost-effective solution for illuminating streets and public spaces.

- Q:How do solar panels affect the energy independence of a building?

- Solar panels can greatly enhance the energy independence of a building by converting sunlight into electricity. By generating their own clean and renewable energy, buildings with solar panels can reduce their reliance on traditional energy sources such as fossil fuels or the power grid. This not only decreases the building's carbon footprint and environmental impact but also provides a more reliable and sustainable source of energy, ultimately leading to greater energy independence.

- Q:Can solar panels be used for heating a greenhouse?

- Yes, solar panels can be used for heating a greenhouse. Solar panels can generate electricity, which can then be used to power heating systems in a greenhouse. Additionally, solar thermal panels can directly capture the sun's heat and transfer it to the greenhouse, providing an efficient and sustainable heating solution.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Solar Cells A Grade and B Grade 3BB and 4BB with High Efficiency 17.6%

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 watt

- Supply Capability:

- 100000000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords