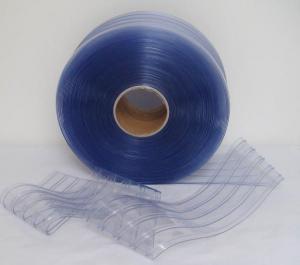

Soft vertical blinds new styles curtain blind curtain

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 500000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Speicification of sunscreen blind curtains roller blind for day and night zebra curtain :

Material : PVC

Colors: different colors are available

Size : 2.8m x30m

Edge: high difination and never loose edge

Description of Soft vertical blinds new styles curtain

1. It was created on the base of traditional vertical blind,not only have the function of controlling the light,but possess the advantage of soft fabrics.

2. These products are towards to high-end market, with broad market and high profits, we will also protct your markt at the beginning, less the pressure of the competition.

3. Supply exquisite sample books for your promotion.

4. Provide service of products consultation and repurchasing components, such as accessaries, mould, CD for ready made market.

Specifications

Soft vertical blind fabric

Composition:80%polyester + 20% RM

Weight per M2: 205g +/- 5%

Color fastness: 7-8 grade

Width:280c

Packing & delivery of sunscreen blind curtains roller blind for day and night zebra curtain :

Packing : 30m per roll, inner with plastic tube then into plastic bag .

Details: strong enough and waterproof

Delivery time : 20days after confirmed orders.

Advantage of our products vertical blind curtains :

1. Rich series and various colors: with the concise and fashionabl design, Hanas is widely used in villa, star hotel, coffee bar, western restaurant.

2, Material and machines: Korea yarn and SMIT weaving machine from Italy.

3. Environtal friendly: passed SGS environmental and ecological testing.

4. Quality assured: professional Q'C team, 5 senior engineers with 20 more years' experience.

5. Sprite Service: products' consultation, exquiste catalogues, components purchasing, assembling traning, etc.

6. Delivery guarantee: within 25 days after receiving the prepayment for first order.

- Q:How many kinds of plastic fiber can be divided into? What's the effect of each?

- Plastic is a kind of macromolecule organic material with resin as its main component. It can form a definite shape at a certain temperature and pressure and maintain a definite shape at normal temperature.

- Q:How does plastic contribute to the longevity of home appliances?

- Plastic contributes to the longevity of home appliances by providing durability and resistance to wear and tear, as well as offering insulation and protection against moisture and corrosion. Additionally, plastic components often have lighter weight, making appliances easier to handle and transport, while also reducing the risk of damage from impacts or accidents.

- Q:Are there any specific guidelines for storing or transporting plastic parts for home appliances?

- Yes, there are specific guidelines for storing and transporting plastic parts for home appliances. It is important to store them in a dry and cool environment to prevent warping or melting. When transporting, it is recommended to use protective packaging materials like bubble wrap or foam to prevent any damage during transit. Additionally, it is crucial to handle the parts with care and avoid placing heavy objects on top of them to avoid deformation.

- Q:Are plastic home appliances more affordable than those made from other materials?

- Plastic home appliances are generally more affordable than those made from other materials due to the lower production costs associated with plastic.

- Q:Are there any health concerns with plastic parts in electric toothbrushes?

- Yes, there can be health concerns with plastic parts in electric toothbrushes. Plastic parts may contain harmful chemicals such as BPA (bisphenol A) or phthalates, which can potentially leach into the mouth during brushing. Long-term exposure to these chemicals has been linked to various health issues, including hormonal disruptions and potential risks to reproductive health. It is advisable to opt for toothbrushes made from BPA-free and phthalate-free plastics or consider alternative toothbrush options, such as those made from sustainable materials like bamboo or biodegradable plastics.

- Q:How does the use of plastic in home appliances impact the overall reliability of the appliance?

- The use of plastic in home appliances can impact the overall reliability of the appliance in various ways. While plastic components can contribute to cost-effectiveness and lighter weight, they may be prone to wear and tear, leading to reduced durability. Plastic parts can also be more susceptible to cracking, melting, or warping under high temperatures or heavy usage. However, advancements in plastic technology have allowed for the production of more durable and heat-resistant materials, mitigating some of these concerns. Ultimately, the impact of plastic on appliance reliability depends on the quality of the plastic used, the design of the appliance, and its intended usage.

- Q:How does plastic affect the energy efficiency of home appliances?

- Plastic materials used in home appliances can have both positive and negative effects on energy efficiency. On one hand, plastic components can help reduce the overall weight of appliances, making them easier to transport and potentially reducing energy consumption during operation. Additionally, plastic insulation can improve thermal efficiency in appliances such as refrigerators, reducing the amount of energy needed to maintain desired temperatures. On the other hand, the production, use, and disposal of plastic can contribute to environmental issues and energy consumption during their lifecycle. Proper manufacturing and disposal practices, along with the use of energy-efficient plastics, can help mitigate these negative impacts and enhance the overall energy efficiency of home appliances.

- Q:What are the main considerations in choosing the chemical resistance of plastic for home appliances?

- The main considerations in choosing the chemical resistance of plastic for home appliances include the type of chemicals the plastic will come into contact with, the frequency and duration of exposure, the temperature at which the plastic will be used, the potential for chemical interactions or reactions, and the overall durability and lifespan of the plastic in the given environment.

- Q:Can plastic parts in blenders and food processors handle the constant pressure and force from blending and chopping?

- Yes, plastic parts in blenders and food processors are designed to handle the constant pressure and force from blending and chopping. Manufacturers use durable and high-quality plastics, such as BPA-free and food-grade materials, that are specifically engineered to withstand the stresses and strains of these applications. These plastic parts are tested for durability and strength to ensure they can handle the repetitive motions and forces involved in blending and chopping without any issues.

- Q:Can home appliance plastics be easily sanitized to maintain hygiene?

- Yes, home appliance plastics can be easily sanitized to maintain hygiene.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Soft vertical blinds new styles curtain blind curtain

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 500000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products