Sodium Allyl Sulfonate (SAS) for nickel plating

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.5

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Sodium Allyl Sulfonate

Product Name: Sodium Allyl Sulfonate (SAS)

Molecular Formula: C3H5SO3Na

CAS NO.: 2495-39-8

Structural Formula: CH2=CH-CH2-SO3Na

Molecular Weight: 144.1

Index:

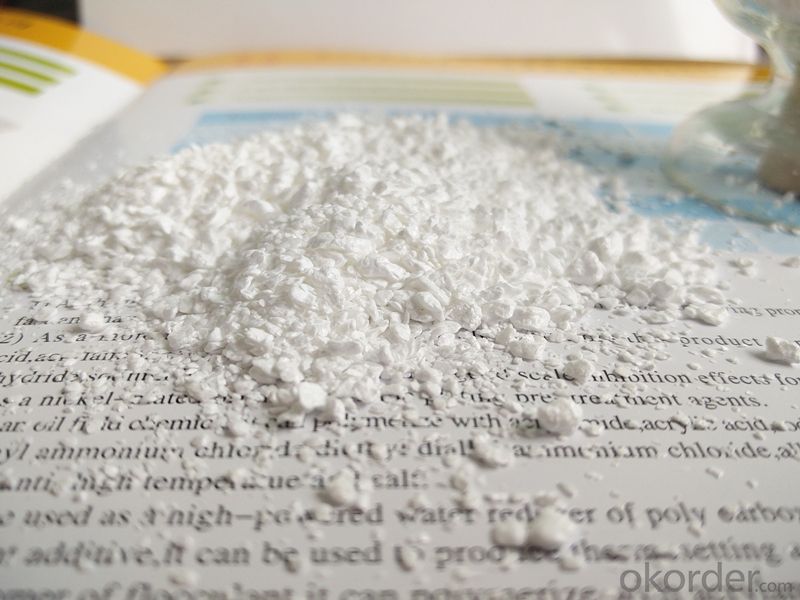

Technological Index | TopGrade | First Grade | Qualified |

Content(dry basis) % ≥ | 98 | 97 | 95 |

NaCl % ≤ | 1.0 | 1.3 | 1.5 |

Na2SO3 % ≤ | 0.1 | 0.1 | 0.3 |

Fe2+ % ≤ | 0.0003 | 0.0003 | 0.003 |

H2O % ≤ | 0.8 | 1.5 | 3.0 |

Functions:

1)As the third monomer of acrylic fiber,this product can improve the dying properties,the heat resistance and flexibility of fibers,so they can absorb color fast and have strong fastness and bright color.

2)As a monomer of corrosion and scale inhibitors,this product can be used in water treatment chemicals.It can polymerize with acrylic acid,acrylamide,maleic anhydride,sodium hypophosphite and has good scale inhibition effects for calcium phosphate,zinc salts,carbonate calcium and calcium sulfate.

3)As a nickel-plated brightener in the plating pre-treatment agents.

4)As an oil field chemical,it can polymerize with acrylamide,acrylic acid,sodium humate,acrylamido propyl trimthyl ammonium chloride,acrylamido-ethyl-2-methyl ammonium chloride,diethyl diallyl ammonium chloride,allyl trimethyl ammonium chloride to be dispersants,fluid loss agent and have remarkable effect in anti-high temperatue and salt.

5)It can be used as a high-powered water reducer of poly carboxylic acid to low the water added of products and retard well.

6)As a paint additive,it can be used to produce thermosetting acrylic resin and coating dispersant to increase the water-solubility.

7)As a monomer of flocculant,it can polymerize with acrylamide.

8)It can polymerize with methyl acrylic acid,it aconic acid to be a dispersant.

9)It can be used to mak CPPL and high water-absorbing resin in electronics and materials processing.

10)It can polymerize with sodium acrylate,styrene-acrylic emulsion,polyvinyl alcohl to improve fertilizer about red soil and strenghthen absorb ammonium ion,nitrate ion.

11) It could be used as one medical intermediate.

12) Used in the antistatic agent, it can achieve the internal antistatic affect in two ways and make electric conduction passageway by which electric charge can get to the ground lead. It can also be used for lubricating and mold unloading.

Packing:

20kg/bag in a PP woven bag with PE inner liner, or according to the customers. 16Tons/20’GP.

Attention:

1) This product is hazardous to health, prevent ingestion of this product.

2) Rain proof, wet proof and resistant of the exposure to sunlight when transportation.

3) Be store in a dry and cool place.

- Q:I have an 01‘ BMW 330i which requires premium gas with a minimum of 91 octane. I‘ve also seen some fuel additives which clean out the engine of gunk and claim to do wonders for the car. Also, a little more kick out of a clean engine can be provided by the octane. Would this be a good idea.The car is almost 10 years old, and even though I‘ve always used premium gas, I‘m sure that some buildup in the engine has to have occurred. Would this be ideal or is it merely a quick fix?Also, I‘m considering some permanent alterations. Nothing too expensive but a good cost benefit change like a kn air filter or something a bit more extensive. Any ideas or suggestions or where to start?

- This happens often, especially if the couple is young and just starting out in their lives and careers. Assuming the distance is great and the time, like University or a new Job, is just as great, It's really asking to much, to expect the love to last. Married people get divorced all the time, and they live side by side, which of course, may be the reason for the divorce. lol Other couples split up, love sadly, for most of us, is not eternal, but often fleeting. Although while we are in love, we believe it to be so. We all need company and companionship, and other people close to us. In long distance, you can always stay in touch, these days, but you still need some special person in your life, unless you intend to stay at home, with a good book or TV etc. Not the best way to spend ones life.

- Q:and how do we apply them in photoshop?I have a presentation to produce and I get how they are made but I don‘t understand why we use them or how we use them in photoshop.Any help will be appreciated, Thanks

- subtractive colors is like using crayons or paint. it is the method used for mixing colors that is familiar to most people from childhood. primary colors are red, yellow and blue. additive colors is like using light itself. for example, someone lighting a stage would use additive colors. primary colors are red, green and blue. use whichever method works best for you. it doesn't matter to the end viewer.

- Q:what are some important food additives we need?

- Let's see.the only one coming to mind this early in the morning would be something like iodine. This additive is used in commercial salt. It was added to salt in an attempt to prevent a condition known as goiter. Goiter is a condition in which your thryoid is affected and begins to enlarge. The presence of iodine was/is used in treating this mallady. I am uncertain how prevalent this disease still is around the world. If you take a peek at ipedia's write up, you'll see a photo of a patient with goiter. Not a pretty sight. Another important additive within products or just from the standpoint of increased consumption would be something like Vitamin C. Back in the day, sailors and other seafaring people who had little or no access to fresh citrus fruits would develop a disease known as scurvy. Their gums would start to bleed excessively.gross huh? That's where the term/slang scurvy dog came from. So, once the link between lack of Vitamin C and this disease became known, then lots of limes were then brought with them on their long sea voyages. That's also where the term/slang 'limeys came from.

- Q:can anybody explain what a additive inverse is? i mean as in math wise, like property.also, is 6+(-6)0 a additive inverse or additive identity?

- While I have not heard of electric blankets being harmful, except for the inherent shock or fire hazard, there have been concerns about high voltage transmission wires having an effect on people with its electromagnetism. The heater wires in the blanket operate at much lesser voltage that the high tension lines, but, they are so much closer. Something to consider.

- Q:One of my cats has bad teeth and while I‘ve been brushing them, I‘ve also been adding CET Aqua Dent Water Additive to their water. However, since they drink from a Drinkwell fountain that has a filter, I‘m worried it‘s just filtering out the additive. Can anyone who also uses a filtered fountain with a dental additive shine some light on this for me?Thanks. :)

- This is a very interesting question! I honestly do not know the answer, but I would be more concerned that the water additive won't solve the dental problem - a professional veterinary cleaning to start, and then daily brushing of the teeth with cat toothpaste will probably be more effective. Can you still smell the additive after the water has been filtered? That may help you determine if it's being filtered out or not.

- Q:Besides compost, what are some good garden soil additives and where can I get them?

- There are many additives for soil. Some can completely change the state of your garden and some are just snake oil without any function but they are all designed to add to your soil what it is lacking. Before you spend any money on amending your soil you want to know what kind of soil you have and what it's missing. You can't fix your car without first knowing the problem and parts you'll need, same goes for soil. If you are partially interested in your garden you could add manure which is a lot like compost. You could get ahold of some topsoil and add that, you could also turn in a couple bags of miracle grow potting soil or a hand full or two of ozmocote. But if you are very interested and curious to know your soil invest in a cheap soil test kit. Knowing the type of soil you have, it's Ph and nutrient content is like knowing your kid's medical needs. You'll be able to buy exactly what you need to maintain a healthy growing medium.

- Q:I need some disadvantages of additives in food. They don‘t have to be extremely detailed - it‘s only for a piece of science homework. Thank you x

- Even though it WAS mint you have at least 800 bucks in plastic if it was replaced with original stuff.Chalk that one up as a lost cause-you would be lucky to get 800 bucks from the insurance company for it.

- Q:How can we prove that the additive inverse -u is unique of a vector space?

- Assume that the vector u has two additive inverses, call them v and v' Then by definition: u + v 0 u + v' 0 Those two quantities are equal, so: u + v u + v' Now add v to the left side of each: v + u + v v + u + v' But we can say v+u 0 so: 0 + v 0 + v' v v'

- Q:what is the best oil additive?

- you don,t need that stuff ! most oil today already has additive in it ! but if you want some then the best i ran onto is BG oil additive ! garages sells it and it,s not cheap !

- Q:The animaniacs do a song about food additives. where can i find the lyrics for that song?

- Animaniacs Friendship Song

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Sodium Allyl Sulfonate (SAS) for nickel plating

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.5

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords