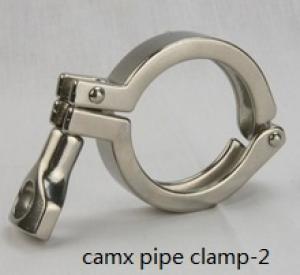

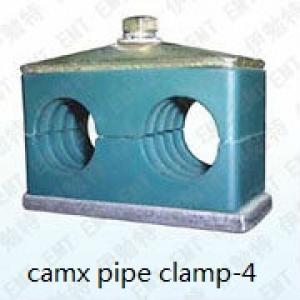

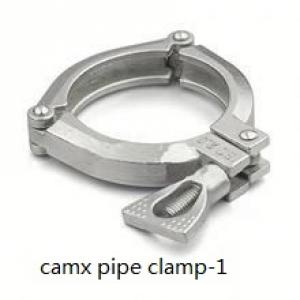

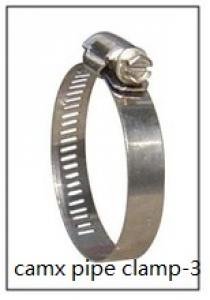

snap concrete pump pipe clamp coupling

- Loading Port:

- Qingdao

- Payment Terms:

- TT LC

- Min Order Qty:

- 100 pcs pc

- Supply Capability:

- 300000pcs Per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Usage: Pipe Clamp

Material: steel、matel;Galvanized iron ,stainles

Band width:3mm/20mm

Connection:welding

Model number:As your requirement

Structure:Swivel clamp

Certificate:ISO9001:2008

Feature:

1.Use the open internal and external circle structure,and with screw fixed.It is effectively to solve the problem that when small diameter solft tube connect the hared tube,it is easy appear dead angle,and liquid or gas leakage problem.Easy structure,Easy maked.

2.Edge is no burrfree,it is ability to prevent the tube damaged

3.By a efficiently hydrogen relief treatment,long-term use needn't to worry fracture and other problems

Surface: zinc plated Packaging

4.Accord with DIN3017 Standard.By 48 hours salt and fog test,it has a good corrosion resistance

5.By our last 48 hours elastic test,to insure a high strength mechanical properties.

6.Easy to fix.

Working Temp: -40 ℃ ~ 110 ℃

Size:3/8" 1/2" 3/4" 1" 1 1/4" 1 1/2" 2" 2 1/2

Structure: Suspension Clamp and so on On-time shipment and pre-shipment product quality safeguards clamp is mainly used in automobiles,tractors, ships, gasoline engine, and so on each kind of mechanical

device for oil, gas, hydraulic hose connector, various types of

rubber tube interface must join parts fastening.

Detail: plywood case ,pallets or any other package as buyer's requirements

Delivery Detail: about 20-30days

Material: steel、matel;Galvanized iron ,stainles

Band width:3mm/20mm

Connection:welding

Model number:As your requirement

Structure:Swivel clamp

Certificate:ISO9001:2008

Feature:

1.Use the open internal and external circle structure,and with screw fixed.It is effectively to solve the problem that when small diameter solft tube connect the hared tube,it is easy appear dead angle,and liquid or gas leakage problem.Easy structure,Easy maked.

2.Edge is no burrfree,it is ability to prevent the tube damaged

3.By a efficiently hydrogen relief treatment,long-term use needn't to worry fracture and other problems

Surface: zinc plated Packaging

4.Accord with DIN3017 Standard.By 48 hours salt and fog test,it has a good corrosion resistance

5.By our last 48 hours elastic test,to insure a high strength mechanical properties.

6.Easy to fix.

Working Temp: -40 ℃ ~ 110 ℃

Size:3/8" 1/2" 3/4" 1" 1 1/4" 1 1/2" 2" 2 1/2

Structure: Suspension Clamp and so on On-time shipment and pre-shipment product quality safeguards clamp is mainly used in automobiles,tractors, ships, gasoline engine, and so on each kind of mechanical

device for oil, gas, hydraulic hose connector, various types of

rubber tube interface must join parts fastening.

Detail: plywood case ,pallets or any other package as buyer's requirements

Delivery Detail: about 20-30days

- Q:How much power does a computer power 297W require?

- Genuine 300 watts is enoughThis configuration is not unique, I use pliers type meter over the general application, power consumption is about 120W, graphics card power consumption of about 130W

- Q:The difference between digital multimeter and caliper type multimeter

- Clamp type ammeter and multimeter principle using different methods are not the same. As long as the table clamp clamp a wire can measure the current, suitable for high current measurement, the multimeter measuring current but is connected to the circuit, otherwise can not be measured. The multimeter measured current to the circuit are connected in series go

- Q:What's the difference between a caliper meter and an ordinary multimeter?

- The ordinary multimeter can measure current, but the table access circuit, which belongs to the "lossy" detection and tandem process category, too much trouble, it is a waste of time; the hardcore repairman will do two special pens, but only reduce the complexity of access, or inconvenient.

- Q:How can I measure the voltage and current with a clamp?

- Using the method of measuring current clamp meter 1, before measuring clamp meter mechanical zero; 2, select the appropriate clamp meter range: from large to small range or see rating estimation; 3, when using the clamp meter minimum range measurement, the reading is not obvious, can be measured wire around a few turns the number of turns, turns to the jaw central subject is reading indication / full range X = partial x turns; 4, when measured, should make the measured conductor in the central and the jaw, jaw tight closing, in order to reduce the error; 5, after the measurement, to convert the clamp meter switch in the most in the range.

- Q:What is the voltage of the clamp table?

- The clamp type meter can not measure voltage by the way of clamp!

- Q:Clamp ammeters on what hold is

- Clamp current meter measurement is the current instantaneous value of current, press the HOLD button to keep you press the instantaneous value

- Q:But after 3 minutes on the machine, there is no electricity, what's the matter?

- First of all, I suggest you make sure the compressor has no work and listen to the sound. No words starting with his hand to open the machine shell surface of compressor, see is not hot, hot water is available as the compressor cooling after the boot, if opened, let him run for a period of time, or if that is automatically shut down the compressor overheating protection. There are many conditions that cause overheating protection. The main points are normal and abnormal. Normal is when the air conditioning works in very harsh conditions, such as very high ambient temperature, refrigeration, and press load is too large to protect. Non normal, mainly the system problems, such as Freon shortage, the pipeline blocked, the fan does not turn, and so on, according to the specific circumstances of the decision.

- Q:How to measure the current limiting resistor of electrostatic ring?

- The grounding resistance tester model is ZC29B. There are three lines: 20 meters of ground pile and 40 meter stake respectively

- Q:Clamp meter cable direction? Why do I change the direction of measurement with a cable, the current is not the same

- Clamp type ammeter, clamp wire, current measurement method can only measure alternating current, the battery should be charged dc.

- Q:Air conditioning suddenly does not cool down, what's the matter?

- Two reasons for the non cooling of air conditioning: the voltage of power supply is not enough: the solution is to maintain normal supply voltage.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

snap concrete pump pipe clamp coupling

- Loading Port:

- Qingdao

- Payment Terms:

- TT LC

- Min Order Qty:

- 100 pcs pc

- Supply Capability:

- 300000pcs Per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords