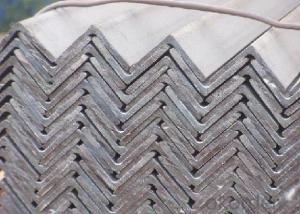

Small angle, angle steel, galvanized angle steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Angle called angle, the steel strip is perpendicular to each other on both sides into angular.Divided into equilateral angle steel and ranging from side angle. Two equilateral angle steel edge width is the same. The specification is expressed by edge width * width * thick edgenumber of millimeters. Such as "/ 30 x 30 x 3", namely that equilateral angle steel edge widthof 30 mm, 3 mm thick edge. Can also be used to model representation, model is the wideangle 3# cm, such as. The model does not represent the same type in different edge thickness size, thus in the contract and other documents on the angle of the edge width, edgethick size fill in complete, avoid alone represented by type. Hot rolled equilateral angle steelspecifications for 2#-20#. Angle according to the different needs of structure composed of a variety of stress components, can also be used as a component of the connections between the. Widely used in a variety of architectural and engineering structures, such as beams,bridges, towers, hoisting and conveying machinery, ships, industrial furnace, reactor,container frame and warehouse.

Mainly divided into equilateral angle steel, equilateral angle steel two categories, includingunequal angle can be divided into equal thickness and unequal thickness ranging from two.

Angle specifications with the side length of the size and edge thickness. At present, the domestic steel specifications for 2 - 20 cm in length, number of numbers, the same horn steel often have 2 - 7 different edge thickness. The actual size and inlet angle marked on both sides of the thickness and indicate the relevant standards. The general length of more than 12.5cm for large angle steel, 12.5cm - 5cm for the medium angle, length of 5cm for smallangle.

Inlet and outlet angle steel orders generally required the use specifications in the steel,carbon structural steel grades as appropriate. Is the angle in addition to standard number, nospecific composition and performance series.

Angle steel delivery length is divided into fixed length, size two, domestic steel length range is3 - 9m, 4 12M, 4 19m, 6 19m four range according to different specifications. Japanese steellength ranges from 6 to 15m.

Section of unequal angle height according to the long edge of the width to calculate the non equilateral angle steel. Refer to section angle and side length is not equal to the steel. Is a kind of angle steel. The length from 25mm * 16mm to 200mm * l25mm. By the hot rolling mill rolling in. General scalene angle steel specifications: thickness of 4-18mm / 50*32-- / 200*125

Equilateral angle steel is widely used in all kinds of metal structures, bridges, machinery manufacturing and shipbuilding industry, all kinds of architectural and engineering structures,such as beams, bridges, towers, hoisting and conveying machinery, ships, industrial furnace,reactor, container frame and warehouse etc.

- Q:How are steel angles protected against chemical exposure?

- There are several methods available to protect steel angles from chemical exposure. One effective approach involves applying protective coatings, such as epoxy or polyurethane coatings. These coatings serve as a barrier between the steel angle and any chemicals it may encounter. They are designed to resist chemical attacks and shield the steel from corrosion or degradation. Another method to safeguard steel angles against chemical exposure is by using stainless steel. Stainless steel contains a significant amount of chromium, which creates a protective oxide layer on the steel's surface. This oxide layer acts as a barrier, preventing chemical attacks and preserving the integrity of the steel angle. Furthermore, acid-resistant materials can be employed to protect steel angles. These materials are specifically designed to withstand the corrosive effects of chemicals. They can be used to line tanks or containers that store or transport chemicals, shielding the steel angle from direct contact and minimizing the risk of corrosion or damage. Regular maintenance and inspections play a crucial role in safeguarding steel angles from chemical exposure. By inspecting the angles for any signs of damage or corrosion, early detection and intervention are possible. Damaged protective coatings can be repaired or replaced promptly, ensuring continuous protection for the steel angle. In conclusion, steel angles can be effectively protected from chemical exposure through the application of protective coatings, the utilization of stainless steel, the use of acid-resistant materials, and regular maintenance and inspections. These measures are essential in preventing corrosion, degradation, and damage, thereby maximizing the longevity and performance of steel angles in chemical environments.

- Q:Can steel angles be used for handrails?

- Yes, steel angles can be used for handrails. Steel angles are often used as a structural component for handrails due to their strength and durability. They can provide a sturdy and stable support for handrails in various applications.

- Q:What is the typical yield stress of steel angles?

- The yield stress of steel angles can differ based on the grade and type of steel utilized. Nevertheless, for frequently employed carbon steels, the yield stress typically varies between 36,000 and 50,000 psi. This indicates that the steel angles can endure a specific level of stress or pressure prior to experiencing deformation or permanent alteration in shape. It is crucial to acknowledge that distinct steel alloys and treatments can lead to different yield stresses. Therefore, it is essential to refer to the specific specifications or reference materials pertaining to the particular steel angle in question.

- Q:Can steel angles be used as support brackets?

- Indeed, support brackets can be fashioned from steel angles. In construction, steel angles find widespread usage in the provision of structural support and stability. They possess versatility and can be conveniently affixed to walls, floors, or alternative surfaces, thereby engendering a robust and dependable support framework. Frequently, steel angles are employed in supporting beams, joists, or shelves, and they can additionally serve as corner brackets to fortify joints or connections. The exceptional potency and resilience of steel render it an exemplary selection for support brackets, guaranteeing their ability to endure substantial loads and furnish enduring support.

- Q:What are the different standards for steel angles?

- Steel angles, commonly used in construction and industrial applications, adhere to various standards to meet specific requirements. The American Society for Testing and Materials (ASTM) standard, specifically ASTM A36, is widely recognized and specifies the chemical composition, mechanical properties, and tolerances of steel angles. This standard is suitable for general structural purposes and is available in different sizes and lengths. Similarly, the European standard, known as EN 10025, encompasses multiple grades of steel angles, including S235, S275, and S355, which correspond to different yield strengths. These angles find extensive use in construction, machinery, and engineering industries throughout Europe. Country-specific standards also exist, such as the Japanese Industrial Standards (JIS) and the British Standards (BS). JIS G3101, a renowned standard in Japan, outlines the specifications for hot-rolled steel angles used in general structures. Meanwhile, BS EN 10056, a British standard, provides specifications for steel angles employed in construction. Furthermore, specialized standards cater to specific applications, such as marine-grade steel angles that withstand corrosion in saltwater environments. These standards, like ASTM A588, impose additional requirements for chemical composition and mechanical properties to ensure durability in harsh conditions. In conclusion, the diversity of steel angle standards guarantees that these structural shapes fulfill precise requirements regarding strength, durability, and compatibility with various construction and industrial applications. To ensure compliance with necessary specifications, it is crucial to consult the appropriate standard when selecting steel angles.

- Q:How do steel angles perform in terms of sound reflection or absorption?

- Steel angles are typically not effective in terms of sound absorption. They tend to reflect sound rather than absorb it due to their dense and rigid structure.

- Q:Can steel angles be bent or formed?

- Yes, steel angles can be bent or formed using various metalworking techniques such as hot bending, cold bending, or using specialized machinery like a press brake.

- Q:How do you measure the dimensions of a steel angle?

- To determine the dimensions of a steel angle, a combination of tools such as a measuring tape or ruler, a protractor, and a square can be used. Begin by measuring the length of one side of the angle using a measuring tape or ruler. Position the tape or ruler along the side of the angle and observe the measurement. Subsequently, measure the length of the other side of the angle in the same manner. Ensure that the starting point is the same as the first side for precise results. For measuring the angle itself, employ a protractor. Align the protractor's base with one side of the angle and verify that the other side corresponds to the appropriate degree marking on the protractor. Consult the protractor's reading to ascertain the angle of the steel angle. Lastly, a square can be utilized to confirm if the angle truly measures 90 degrees. Place the square against the two sides of the angle and confirm that it perfectly aligns with both sides. If alignment is achieved, then the angle is, indeed, 90 degrees. Please bear in mind that these measurements may be approximate and could slightly differ due to manufacturing tolerances.

- Q:What are the different types of connections used for steel angles in educational institutions?

- There are several types of connections commonly used for steel angles in educational institutions. These include bolted connections, welded connections, and clip angles. Bolted connections involve using bolts and nuts to secure the steel angles together. Welded connections, on the other hand, involve fusing the steel angles together using heat. Clip angles are small pieces of steel that are used to connect and reinforce the steel angles. Each type of connection has its own advantages and disadvantages, and the choice depends on factors such as the load requirements, cost, and construction method.

- Q:How are steel angles installed?

- Steel angles are typically installed using a few simple steps. First, you will need to mark the desired location for the angle on the surface or structure where it will be installed. Next, using a level and measuring tape, ensure that the angle is aligned correctly and mark the positions for the screw or bolt holes. Once the markings are made, you will need to pre-drill the holes using a drill bit that is slightly smaller than the diameter of the screws or bolts you will be using. This will prevent the steel angle from cracking or splitting during installation. After pre-drilling the holes, place the steel angle back in position and align the holes with the markings on the surface. Use a wrench or screwdriver to tighten the screws or bolts securely, making sure the angle is firmly attached. It is important to follow the manufacturer's instructions and recommendations for the specific type and size of steel angle being installed. Additionally, ensure that the surface or structure where the angle is being installed is able to support the weight and load that will be applied to it. Overall, steel angles are relatively simple to install and provide excellent structural support in various applications such as construction, manufacturing, and DIY projects.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Small angle, angle steel, galvanized angle steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords