Sliver Stand up Pouch with Window Clear for Food packing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 100000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of Sliver Stand up Pouch with Window Clear for Food packing:

Sliver Stand up Pouch with Window Clear for Food packing are processing with imported materials,we have introduced advanced equipment and high manufacturing technology into production lines and we have rich experience in producing plastic bag .can meet your needs by fulfilling your specification in a positive manner .High efficiency and speed are our working style .high quality and competitive price are our pursuit.

Sliver Stand up Pouch with Window Clear for Food packing mainly used for packing all kinds of food packing etc.

2. Main Features Sliver Stand up Pouch with Window Clear for Food packing

Excellent quality bag

Experienced manufacturer service will be given

Eco friendly and good printing

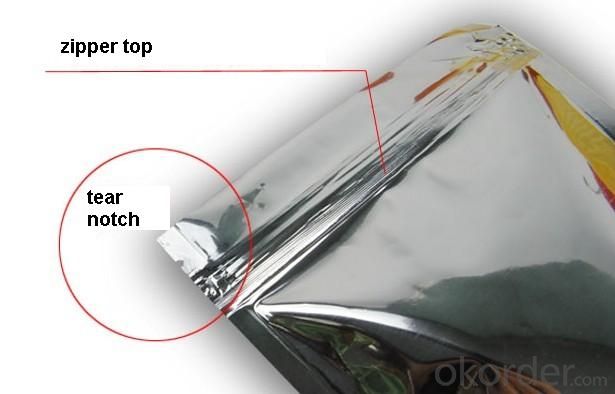

3. Sliver Stand up Pouch with Window Clear for Food packing Photos:

4. Sliver Stand up Pouch with Window Clear for Food packing Specification:

1. Material: Laminated material

2.Size:20*750px or Customized

3.Thickness:10-200um

4.Production Flow:

Pre-press: Digital proof & rotogravure-cylinders production (engraving),

Rotogravure printing

Bag making

Quality checkingShipping

5.FAQ of Sliver Stand up Pouch with Window Clear for Food packing Specification:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Plastic packing bags can supply you all kind of packing bags you wanted.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q:What is the material for edible fungus stick packing bag?

- High pressure polypropylene bag, the bag has the characteristics of high temperature and high pressure, it can reach 120 degrees and not easily deformed. It is the first choice for factory cultivation.

- Q:How much is the 1 wire in the food packing bag printing industry?

- Now the standard of living has improved, basically the food package. This will improve the product's shelf life, preservation time is longer, more conducive to product sales.

- Q:Is the color of cement packing bags related to cement?

- Portland ash cement, fly ash, silicate sleep and composite Portland cement -- black or blue.The cement packing bags shall clearly indicate the standards of implementation, cement varieties, codes, strength levels, producers' names, production licence marks (QS) and serial numbers, serial numbers, date of packing and net contents.

- Q:Why are some teas not vacuum packed?

- In order to ensure the quality of tea and pure taste, natural, free from external conditions, but also in order to enhance the image of tea, enhance the value of goods, the exquisite packaging of tea is the trend of the times. These unsuitable vacuum packed tea, such as green tea and Longjing, tend to be easily squeezed and packed and can be packed in vacuum packed with nitrogen. Brick tea packaging paper bag packaging form form West Lake Longjing Tea vacuum tea vacuum packing inflatable packaging is a mixture of gases in vacuum and then filled with nitrogen, carbon dioxide and other two or three kinds of single gas or gas. Nitrogen is an inert gas with a density close to the air. It acts as a filling, keeping positive pressure in the bag and protecting the leaves from crushing by atmospheric pressure. Carbon dioxide can make tea into sleep, and maintain the quality of tea.

- Q:Is the packet in the food package a reducing agent or an oxidizing agent?

- In many food packages, the Producers place a packet of antioxidants and note the words "antioxidants, not edible". Its function is to absorb oxygen in the food bag, so that the oxygen level in the bag is controlled at a very low level, to prevent the proliferation of microorganisms in the bag. Because the growth and division of microorganisms require the participation of oxygen, the spores and hyphae of microorganisms are strongly inhibited under anoxic conditions. Thereby, the food in the bag is preserved, and the probability of microbial contamination is reduced.

- Q:What's the raw material of the cement packing bag?

- Plastic recycling machine is the role of the crushed cleaning waste polypropylene, polyethylene block, sheet, pipe, bottle, film, weaving, silk, pressurized heated in the machine, drawing into strips, the cutter into granular for other plastic processing machinery use.

- Q:How do you determine the 210mm*300mm package and determine its version and length?

- Length 21 cm, width 30, vertical roll length suggest up to cooperate with compound printing equipment

- Q:What kind of packaging bag does polysilicon use?

- Polysilicon shall be packed in a clean polyethylene packing bag and sealed;

- Q:How big is the vacuum pack 28*40cm?

- For custom vacuum bags, I would recommend a manufacturer who has customized experience in vacuum bags because it reduces your time cost and offers a lot of advice on packaging design and customization.

- Q:What's the packing of the air in the food package?

- For example, our common bag of potato chips, which is mostly nitrogen N2, a gas filling packaging is fat, on the one hand is the replacement of the original air bag and prolong the shelf life; on the one hand, there is a large amount of gas support chips during transportation and storage, can also be to reduce the impact of fragmentation. You certainly don't want to buy potato chips all over it.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Sliver Stand up Pouch with Window Clear for Food packing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 100000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords