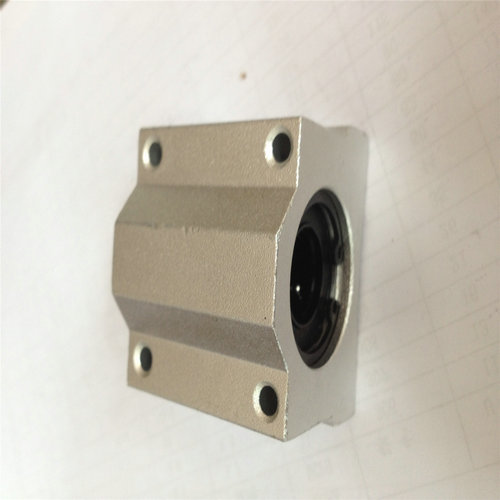

slide bearing absorber bushing plain bearing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

plain bearing, slide bearing, absorber bushing

1.Good load capacity and anti-wear.

2.Widely used in the Lead-free field.

Plain bearing, slide bearing, absorber bushing

We CHANGSHEG BEARING is a direct manufacturer specialized in producing bushings with more than 10 years . We believe that we can provide you the best products and services!

du bush, pump bush, shock absorber bushings

| Max.Load | Static | 250N/mm2 |

| Dynamic | 140N/mm2 | |

| Oscillating | 60N/mm2 | |

| PV limit | Dry | 3.6N/mm2.m/s |

| Oil | 50N/mm2.m/s | |

| Temp.limit | -195°C~+280°C | |

| Friction Coeff. | 0.03~0.20μ | |

| Speed limit | Dry | 2m/s |

| Oil | 5m/s | |

| Thermal conductivity | 2.41Kcal/M.br.c | |

| Coeff. Of linear expansion | 27×10-6per°C | |

- Q:Which is better for plain bearings, copper sleeve and linear bearing?

- The sliding bearing with the copper sleeve with high strength copper alloy (CuZn25Al5, CuZn24Al6Fe3Mn4) as the basic material, according to the use conditions according to a certain proportion in the work surface processing hole and fill in the solid lubricant, copper alloy high strength provides high bearing capacity and solid lubricant can form low friction.Linear bearings are made of steel ballsThe bearing of the sliding bearing is larger, the bearing capacity of the linear bearing is smaller, but the accuracy is high

- Q:What are the differences between rolling bearings and plain bearings? What are their respective applications?

- The second is the movement in different ways, the way of rolling motion the bearing is rolling motion; x0d sliding bearing is sliding, so the situation on the friction is not the same. The general mechanical equipment used in relatively small rolling bearing, high speed, such as motor x0d, Gear box, sliding bearing applications generally in low speed and heavy load conditions, or maintenance and operation of the site maintenance and lubricating oil is difficult, such as ship propulsion shaft x0d.x0d hope my answer to help you.

- Q:What is the bearing force value, how to determine, how to adjust, what is the effect?

- Bearing preload value of the end is lower level put a root diameter of 1mm length 100mm wire (A1, A2), motor or pump mechanical corresponding middle bearing upper same diameter and length of wire (B1), and then fasten the bearing shell and lid, with a screw tightening, then open remove the flat wire, so the bearing force value of s=b1- (a1+a2) /2, mm.

- Q:Failure forms of plain bearings, failure forms of plain bearings

- Failure modes of plain bearings1. abrasive wear: hard particles - abrasives - grinding shaft and bearing surface;2. scratch: shaft surface, hard outline, peak scraping bearing;

- Q:High speed heavy duty important sliding bearing, bearing material with tin base bearing alloy or casting tin bronze?

- 2, lead base bearing alloy, suitable for low speed heavy load, the price is much cheaper than tin, but it is not suitable for high-speed. But the performance is better than that of copper alloy.

- Q:What are the differences between rolling bearings and plain bearings?

- Two, compared with the sliding bearing, deep groove ball bearings shortcomings:1, vibration and noise;2. Radial dimensions larger than plain bearings;3 、 poor ability to withstand impact loading;4 、 under high speed and heavy load, the bearing life is low.

- Q:Bearing bearing belongs to what type of

- The Bush may also be burnt due to excessive load, high temperature, impurities or abnormal viscosity of lubricating oil. The plain bearing is damaged after burning the tile.The bearing load in the bearing is composed of sliding bearings, so called single sliding bearing them there is no difference, as Bush is concerned, in order to reduce friction and wear, so use copper alloy, copper base aluminum tin alloy, tin alloy, Babbitt and so on, they are not standard

- Q:What are the advantages and disadvantages of plain bearings compared with those of rolling bearings?

- (1) types and characteristics of plain bearings1. the sliding bearings are divided according to the load:(1) radial sliding bearing (radial sliding bearing), mainly bearing radial load;(2) thrust bearings are mainly subjected to axial load.2. sliding bearings are suitable for low speed, high precision, heavy load and structural requirements. It is also used at low speed and impact.3. center journal bearing(1) integral type and split fractionThe splitting is usually made up of bearing cap, bearing seat, bearing bush and connecting bolt.(2) the Bush is the key part in the bearing.Bearing materials should have small coefficient of friction, good thermal conductivity, small coefficient of thermal expansion, wear resistance, corrosion resistance, strong adhesive resistance, sufficient mechanical strength and plasticity.(3) requirements for bearing materials: bearing alloy (Babbitt), bronze, bearing materials of special properties, etc..4. thrust plain bearings (understood)(1) the thrust bearing fixed and tilting.(2) the thrust surface of thrust bearing can use the end surface of the shaft, or can make a convex shoulder or thrust the disc in the middle of the shaft.(two) types and characteristics of rolling bearings1. classification of rolling bearingsAccording to the shape of the rolling body is divided into: ball bearings, roller bearings.2. characteristics of rolling bearings(1) advantages:Compared with plain bearings, rolling bearings have the advantages of small frictional resistance, quick starting, high efficiency, simple lubrication and easy replacement.(2) shortcomings:Low impact resistance, noise at high speed, and less working life than liquid lubricated sliding bearings.

- Q:Are plain bearings grease lubricated?

- Most of the general sliding bearing lubricated by lubricating oil, but the type of bearing and bearing seal in the open part, but also the use of sliding grease, most general rolling bearing grease, but when the speed is higher than 4 5m/s, or low temperature to increase the resistance and grease should not be too large, or need a large number of the whole unit and heat or liquid systems together, also need lubricating oil.

- Q:What are the methods of casting plain bearings?

- According to the actual conditions: sand casting, centrifugal casting, casting bar material. There are usually special requirements, such as aircraft use, the use of super large engines, will be based on the use of the effect of casting process. Usually to the metal materials company purchased bearings, bearing bronze (or called Babbitt), many are scrap copper, the use of crucibles, casting sand.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

slide bearing absorber bushing plain bearing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords