Slewing reducer JH08

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

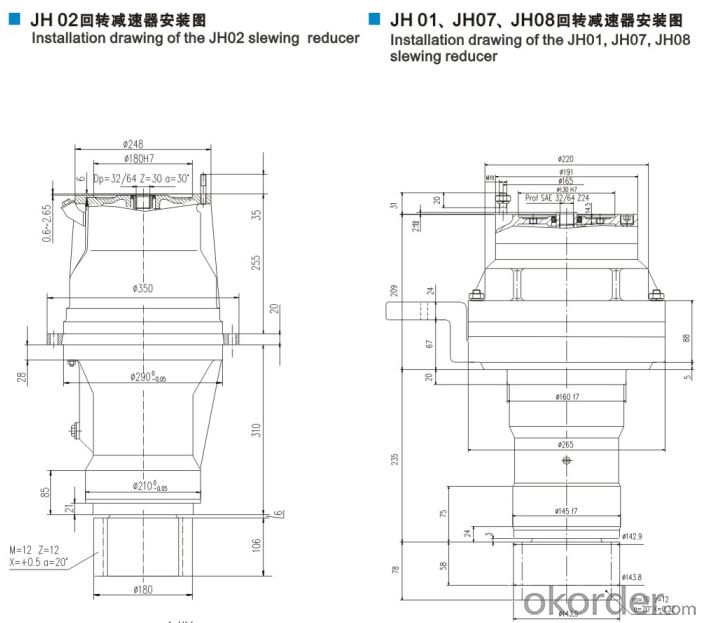

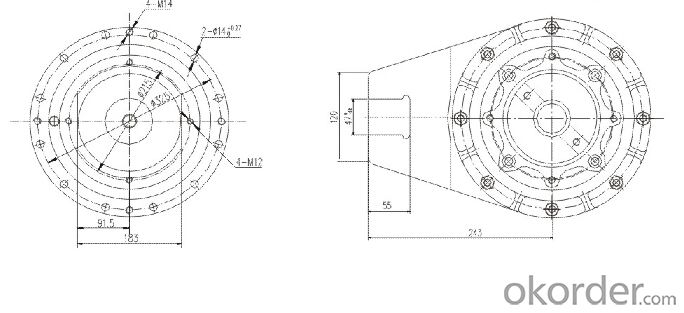

JH series slewing reducer is a hardened face planetary gear reduction device designed by our company according to the advanced foreign technologies with all gears adopting grinding process.The reducer has features of compact structure, stable operation, high transmition efficiency, low noise, long service life, high reliability, etc.Such series reducer can be equipped with torque motor, variable frequency motor and corresponding electrical control system to constitute RCV series slewing mechansim and JHF series slewing mechanism.

Specification

Model:JH08

Ratio:164

Rated output torque (N.M):6000

Output gear Parameter (Customization is avaible):m=10,z=12,x=+0.32

Weight(Kg):90

Parameters of RCV series matching torque motor--Rated stalling torque of the motor (Nm):75,95

Parameters of JHF series matching variable frequency motors--Rated power of the motor kw:4.4,5.5.

Recommended Tower cranes t.m:40~125

- Q:I will soon have folded my 1000th paper crane. What should I do with them after I am done?

- Set them on fire somewhere safe and controlled. The fireplace? String them together and make a long chain to use like garland or streamers. Hang them from the stairs.

- Q:Did not city officials think of the danger if they toppled.

- It takes longer to take them down than Sandy has been a tropical depression.

- Q:HOw to classify tower crane?

- From okorder / are divided into upper rotary tower crane and lower tower crane two broad categories.In which the carrying capacity of the former is high than the latter, in many Construction sites the tower cranes we have seen are On a rotary festival add up on the top of a high tower crane access. According to whether the move can move,tower crane are divided into: walking a line, and fixed ones. The fixed tower crane do not switch, installed in the block of concrete baseBasis, or installed in the form of X-shaped concrete foundation. In the housing construction generally use a fixed style.

- Q:Vtwin doc helped me out with this dam thing recently Im thinking he has the 411! So here goes: My friends coil went bad and we used a single fire coil on a dual fire ignition. V twin doc showed me how to do that. But it still doesnt quite run proper. So here are the settings:Its set at 5900 R.P.M. limit,with advance slope at 9.the rear cylinder is set at 0.Its set on dual fire,its set on electric start.and its set on multi spark not single.Its a crane fireball hi 4e model 8-3100. It cranks for a bit before starting and runs a little rough at low R.P.M. ran just fine with the stock coil.

- Crane Fireball Ignition

- Q:Form the movie Dreamer, daughter of Ben Crane

- Dakota Fanning played the role of Cale Crane in the movie 'Dreamer'. Dreamer is a 2005 film starring Kurt Russell (Ben Crane) and Dakota Fanning, inspired by the true story of an injured racehorse.

- Q:How To Make Origami Crane?

- You okorder and see how to make origami crane step by step

- Q:i have an echo-1 m8a4 cqb it has a crane stock that fits a 9.6 1500mah battery but it wont fit a 2000mah so i want to switch to a full stock but im haveing trouble figuring out how to switch them. does anyone own this gun and know how to do it?

- Ok, I can help. The first step is to take the crane stock off. To do so, extend the stock fully. Then, take the tab you use to extend it, and instead of pushing up to extend it, pull it down and slide the stock off. It make take some force. Be careful of any wires and that you don't break them! Next: take the buffer tube out. Take a long phillips head screw driver and stick it down the shaft. Remove the screw. The whole tube should come out. Don't lose the screw! Next: Install your stock. Next: Screw the screw back in to secure the stock. Done! Make sure the wires are still ok and that they are not pinched!

- Q:how does a crane operator's knowledge of where the centroid is generally located for most uniform objects help them perform their job more safely?

- Usually it is the rigger who attaches the lifting gear not the crane operator who needs to know about centriods and even then the real trick is getting the slings or other lifting devices in the exact place. That tends to be a bit of trial and error unless the lifting points are clearly marked.

- Q:How do you test the tower crane? Myopia can span tower crane? Brother here, please all heroes.

- A tower crane installation scheme, 1, compilation basis, project overview, working environment, 2 workers and 3 endurance calculation and installation equipment for 4, installation procedures, methods and requirements for 5, commissioning record 6, two safety technical measures, safety technical disclosure, three installation foundation concrete test report of four, the tower crane installation and acceptance of table five, safety supervision station issued a permit for six, seven, demolition demolition project safety technical clarificaiton tower crane installation scheme project name: preparation: position (title): Approval: job (title): the construction unit: tower crane installation demolition project, the preparatory work before construction: 1. The tower crane installation position, according to the effective range of the construction requirements, site conditions and the role of tower crane, convenient installation and disassembly, the tower crane configuration in 17 axis to 18 Between the axis, away from the outer wall of 5 meters, with 11 standard section. 2, the basis of the principle, the use of concrete foundation, strictly according to random basis drawing. 3, the examination of concrete pressure report, tower foundation has been completed by design and construction, the safety group acceptance, the basic test block delivery, after the test pressure qualified, must be installed. 4. The installation site is level and the channel is repaired. 5, transport parts admission

- Q:Could anyone tell me how they erect a construction crane.Some how they just are suddenly THERE, as If by magic.It seems as though the Boom part of the crane must be kind of JACKED up into place.That is the only way I can see them getting those GIANT concrete blocks into the back end of the boom. It doesn't seem possible otherwise. The only other thing I can thing of is the bulk of the pieces are brought in by helicoper and attached.Everything kind of makes sence except the Giant concrete blocks used as a counter weight. ALSO, if the blocks are needed to act as counterweigth to the CRANE itself..why doesn't the Crane fall over when it picks stuff up???

- How do they erect the construction cranes? Not very well according to the news of them toppling down of late. Seriously, the cranes are lifted upward one or two floors at a time as the building progresses upward - this is usually accomplished by pulling them up into place with heavy cables and powered winches.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Slewing reducer JH08

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords