Slab copper mould plate/continuous casting copper mould plate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 500 pc/month

- Option:

- Length 3500-3800; Width 700-1000

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Structure of Description

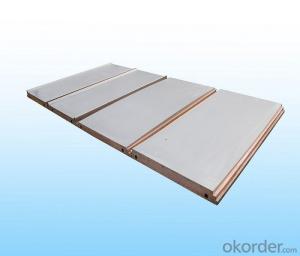

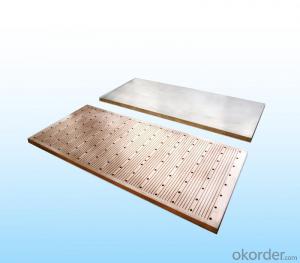

We are supplying High Slab copper mould plate with Size range Length 350-3800 Width 700-1000mm ,Thickness 30-75mm, Material Cr-Zr-Cu, Cu Ag. Coating Ni-Co、Cr、Ni-Fe.which are the world's most Renowned and Reputed;

We supply Copper Moulds of Highest Quality, ensuring Maximum Life, excellent Heat Resistivity and smoothest Casting Operational efficiency.

CNBM, is the leading professional designer and manufacturer for copper mould tubes & plates as well as the complete sets of equipments & spare parts used for hundreds of domestic and abroad steel plants. The copper moulds supplied by CNBM adopt advanced European technology. Nowadays, CNBM is one of the largest copper moulds supplier and exporter with more than 30% market share in domestic market and 5% in the world market. We commit to supply products with world-class quality, competitive price, flexible payment terms, speedy delivery and excellent service, and we can also give technical guidance to help our customers to reduce the cost and increase the productivity. We have got high reputation from various customers all over the world.

2.Main Features

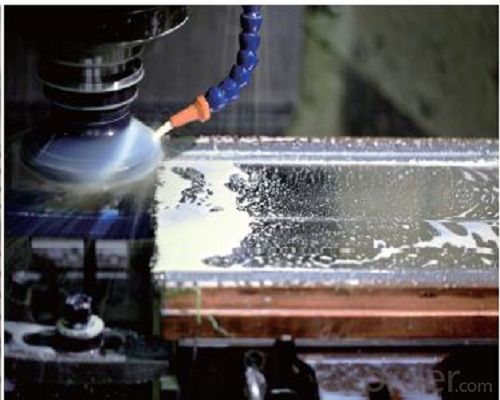

Our design and manufature capacity: with slot single taper, double taper, triple taper, quadruplicate taper, parabolic taper and various of continous taper high effiency copper mould tube.

We are supplying High Slab copper mould plate with Size range Length 350-3800 Width 700-1000mm ,Thickness 30-75mm, Material Cr-Zr-Cu, Cu Ag. Coating Ni-Co、Cr、Ni-Fe.

Steady and high quality,

We can design as per the customer’s specific requirements.

With lots of export expriences all around the world,

Fast shipment; 30-40days for production;

Packing : Strong, export worthy wooden cases.

3. Images

4.Specification

Slab

Length 350-3800mm

Width 700-1000 mm

Thickness 30-75mm

Material Cr-Zr-Cu, Cu Ag. Coating Ni-Co、Cr、Ni-Fe.

* We can design as per the customer’s specific requirements.

- Q:A4 photo paper for home laser printers. Is it coated paper? How many grams are they?

- Glossy paper: glossy paper, in English, is called Photo Quality Glossy Paper. Compared with glossy photo paper, the quality of glossy paper is better than that of glossy paper, and there is a strong gloss on the surface. Not that it's better than glossy paper, because it doesn't shine as thick as photographic paper. Relatively speaking, the price is relatively low, some of the requirements for print print volume high artistic photos and a large number of text materials, but art photos to keep it well, don't let it have the opportunity to fold, so that economic benefits. Typical products are photo quality glossy paper light paper S041126, EPSON Canon GP 101, HP C6039A advanced photo paper, size of common A2, A3 and A4 three, the country also has some high glossy, glossy paper such as gold flagship.

- Q:is canvas the only thing that you can paint with oil paints?

- No! As long as you prime it correctly, you can paint on many surfaces. Just keep in mind painting on something like plywood that even with a primer, some impurities from the wood can leech through the primer and the paint and eventually discolor the work. You can prime wood, paper, lots of stuff.

- Q:Solar energy is becoming popular in rural and remote area in India. Why?

- solar energy popular rural remote area india

- Q:Out of what materials can I make a spark gap? I am trying to make a Spark Gap Transmitter for Morse code- I have already made a very rudimentary telegraph using copper wire, sheet metal, 2 D batteries, and an iron nail (coiling insulated wire around it). It‘s range was about 1 foot (LOL). I digress. What materials can I use for the spark gap?

- The FCC will shut you down - and may fine you. A spark gap transmitter generates a signal over a very wide-band of frequencies. What you are producing is interference.

- Q:For my DC motor, I‘m not quite sure on how to make a commutator.Particularly, what material and how to split it.Oh and does it make difference of what material I use to make the shaft?

- This is a very difficult question to answer, because it is not obvious whether we are talking about a cheap, fragile, little demonstration motor or something more substantial. It's also not obvious what tools or facilities you might have available. In general terms: The segments of the commutator must be electrically insulated or separated from each other and from the shaft or spindle, assuming that you are using a metal shaft. The appropriate ends of the rotor windings must be connected to each commutator segment. Usually soldered. Techniques I've seen used include: Building up a thick (1/4) layer of epoxy resin glue on the metal shaft and then epoxy gluing copper segments made out of copper foil or by hammering flat bits of very thick copper wire. Sticking a short length of wood or plastic rod with a hole through the centre on to the shaft, gluing a short length of copper tube on top of that and then cutting the tube into individual segments using a fine hacksaw blade or Dremmel - type tool.

- Q:Park Power (solar, Wind.)?

- I'd say try to track down the group that manages Hanauma Bay marine preserve in Hawaii. It could be the Parks Recreation Department, City County of Honolulu. But if it's not them, they would know who it is. That park has a little wind turbine on top of each of the lights in the parking lot. I was impressed.

- Q:I had some copper plating used for sealing pipes and I need to seal my aluminum canoe

- We had previously been stamping out every forest fire as soon as it started. We are still doing this. This makes it so that the underbrush grows thick and the forest fires become less and less controllable. Sure ti becomes more prevalent during drought seasons, it always has. If you want to link this to a consequence of AGW, then show a statistically significant increase in the number of droughts. As it stands I get SICK AND TIRED of you warmers linking everythign to AGW and not doing a bit of real analysis. Global warming is supposed to place more H2O in the atmosphere and your response is that placing more H2O in the atmosphere leading to droughts and floods?? That does not even make sense. Sure you use the climate change idiocy to say that every change that can possibly happen in any location is caused by climate change, BUT CLIMATES ARE ALWAYS CHANGING. You need to link it directly to CO2 emissions!!!! And the REAL solution is simple. Let the forest fires go. The reason we do not do this are because we don't want people to die in fire or their houses to go up in flames.

- Q:I‘m getting ready to prep an area that contains a lot of clay soil by adding a lot of compost. As I was digging I noticed both snails and slugs. My questions is.Should I add some type of bait to kill them before I even attempt to start planting my perennials? I‘m not familiar with slugs and read up about placing beer in saucers, but I figure if there is nothing there now, maybe I can combat the problem now with some type of bait by mixing it in the compost. Will this work?I would appreciate your inputthank you!

- it is not air but freeon gasdangerous and probably bet to scrap the fridge it will not work if the pipe is leaking

- Q:Whenever I go to the dollar store, I see tons of items made of metal. Colanders, utensils and spatulas can go for a dollar a piece. Now, recently I have been interested in acquiring some thin, bendable (but sturdy) metal for a few personal art projects, but when I look online for sheet metal, it all costs a fortune in comparison!At the dollar store, I also found some cookie tins that are made with a colored metal (like bronze/brass colors) and I was wondering what that metal is and why it is so cheap. Alternatively if you know where I could get similar metal for cheap, I would appreciate it! I would like to be able to bend the metal into a tube shape, if possible, and thanks in advance.

- do you have a warranty? take it back to the dealership and make the service manager or writer go for a ride with you and show that person your complaint. do it asap.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Slab copper mould plate/continuous casting copper mould plate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 500 pc/month

- Option:

- Length 3500-3800; Width 700-1000

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords