SK-3A water ring vacuum pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

SK-ASeries

Based on SK series, is designed specially for the use of plastics industry. Therefore, many problems have been solved, for instance: incapability to work continuously, in case of sufficient wafter to be draw-out, dirts is resulted from sewage, impossibility to restart work after long pause. It is widely used in Tubing and Molding machinery.Items:SK-0.15A、SK-0.3A、SK-0.5A、SK-0.8A、SK-1.2A、SK-2A、SK-3A,Motor power:0.55~5.5KW,extract capacity :0.15~3(m3/min),Limit vacuum:-0.095MPa。

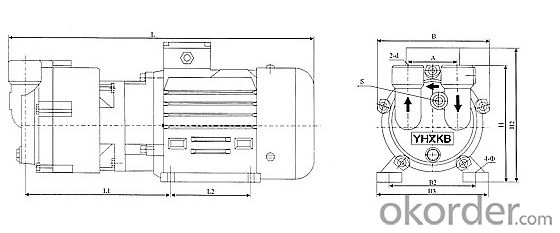

■List of size performance

■List of installation

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

- Q:A residential building with a floor height of 11 stories and a roof height of 33 meters. The height of the water tank is 37.7 meters. The basement is -3.3 meters, only set fire hydrant, fire pump only consider the indoor fire water, fire flow should be 10l/s. Now select a fire pump, concrete should be much traffic, big head, flow determine how? How to determine the head, I hope to say some more detailed, thank you, and there is to explain this question, why is the fire pump lift 120?. Thank you

- Modify the part: (the design of regional common fire pump should be in accordance with the requirements of the original design, building design) contains a 55m high building, and the basement is about 6m, the pump reached in the basement height about 61m (common fire pump should be based on the highest floor of other low floor area, low ring and take in this case, relief measures) 61 levels, the most unfavorable hydrant to reach 0.07MPa (maximum allowable 0.5MPa) plus loss of lift at least about 90m more appropriate, of course can be higher to take relief measures (120 too high), the basic flow of lossless (with the same time there is only one building fire) according to the maximum amount of a building fire water pump set can be, there must be a backup with a preparation, and then select the appropriate pump manufacturer specification query.(the 20 houses on 99m are only shared with a 135m pump)

- Q:What kind of motor does the hydraulic pump need?

- Hydraulic pump is a power component of hydraulic system. It is driven by an engine or an electric motor. It draws oil from the hydraulic tank to form a component of the pressure oil which is sent to the actuating element. Hydraulic pump according to the structure is divided into gear pumps, piston pumps, vane pumps and screw pumps.

- Q:Why does the centrifugal pump close the pressure to start?

- Therefore, the operation rules of multistage centrifugal pumps require that the inlet valve be opened before opening, and the outlet valve is closed. However, the export valve closed time can not be too long, because at this time the medium in the pump cycle, the medium temperature gradually increased, easy to cause mechanical seals, due to lack of lubrication friction and wear or damage.

- Q:I want to know the concrete under 60 type pump performance, it is mainly the pump long spiral bored piles, such as the diameter of the pump, transportation distance, pumping height and so on, thank you!

- HBT60.13.90S performance parametersParameter name unit HBT60.13.90SMaximum theoretical concrete conveying capacity m3/h 69/43Maximum pump outlet pressure Mpa 13/7

- Q:What are the starting and stopping procedures for centrifugal pumps?

- Before using the centrifugal pump, the operation instructions of the centrifugal pump shall be read carefully and the specific operation procedures shall be understood so as to make proper use of the centrifugal pump products. The first step is the operation of centrifugal pump inlet valve of centrifugal pump centrifugal pump for all open cavity filled with liquid, close the outlet valve, start the motor, the motor speed is normal, can gradually open the outlet valve, to adjust to the desired condition. Pay attention to self suction centrifugal pump starts to open the exhaust valve, outlet valve should be opened quickly in the normal operation of the motor, to prevent air inlet pipe off caused by cavitation phenomenon produces centrifugal pump, centrifugal pump vibration phenomenon leads to noise of the smoke is not on the water.

- Q:If you use an ordinary 15W submersible pump, put it in the tank, if the leakage, the fish will hang it?

- Submersible pump even if it really leakage, it will not cause the fish electric shock. The so-called leakage is the submersible pump wire or shell broken, live parts and water contact, the most extreme test is a fire line directly into the fish tank

- Q:What's the pump? Where can I use it?

- A pump is a machine that transports liquids or pumps liquids. Pumps are ubiquitous in life. They can be used to transport liquids such as water, oil, acid and alkali, emulsions, suspensions and liquid metals, as well as liquids, gas mixtures, and liquids containing suspended solids.

- Q:What are the basic technical parameters of the pump?

- The basic parameters of the pump, the basic parameters of the main performance parameters of pump are the following: first, water pump flow Q flow is the amount of liquid in the pump unit time delivery out (volume or quality). The volume of flow with Q that the unit is: m3/s, m3/h, l/s and so on. The quality of flow unit is expressed in Qm. T/h, kg/s and so on. The relationship between mass flow and volume flow is Qm= P Q density in P - liquid (kg/m3, t/m3), room temperature water P =1000kg/m3.

- Q:Is the flow meter in front of the pump or after the pump?

- After the pump, the reasons are as follows, before the pump, you pump fluid through the pump will produce negative pressure in front of the pump, negative pressure on the flow of the life of the impact, the pump will not, Suzhou first Chi meter

- Q:Filter backwash pump for what use, what is the principle of work ah?

- Regeneration of the filter medium is required to regain the filtration capacity of the medium. The regeneration process is mainly accomplished by the backwashing pump (the backwash pump is not a special pump, referring to the pump for the completion of the process). The working principle is through the cleaning liquid from the downstream of the filter into the backwash pump (alkali, acid and water), reverse flushing filter medium, cleaning liquid discharged from the upstream, this process can be attached to the dielectric surface and internal impurities washed away.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

SK-3A water ring vacuum pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords