Sizes For Lipped Channel/steel Frame/c Shape Channel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Description

Lightgage Steel Joist

Features of light steel joist: high performance, easy cut apart, non-deforming, simply installation, dry construction, light weight and environment friendly.

Method to test the keel's quality

1. look. Appearance smooth, no spots.

2. galvanized thickness: 80g/m2( qualified), 100g/m2( A grade), 120g/m2 ( A+ )

We are a manufacturer of steel keel with well-equipped testing equipment and strong technical force.

With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in decoration and other industries.

Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs.

We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

3.Image

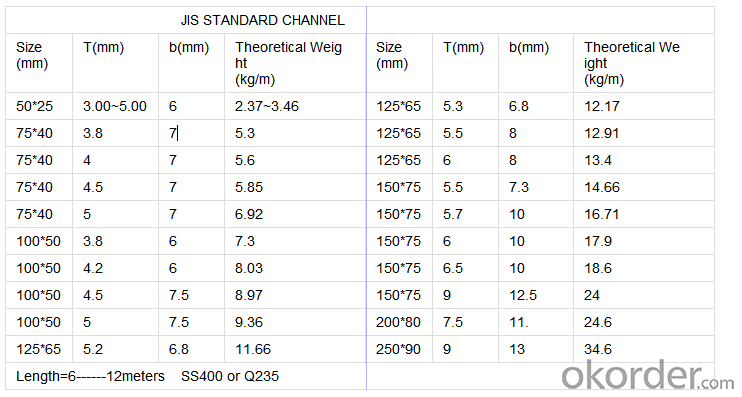

4.Detailed Specification

5.FAQ

zinc galvanized steel strip :

(1)Standard: ASTM, JIS

(2)Steel Grade: Q195

(3)Width :600mm-1500mm

(4)Surface:galvanized or Zinc

Packaging & Delivery

Hot rolled galvanized steel strip

1. thickness: 0.18mm - 1.5mm

2. width: 20mm - 580mm

3. material: Q195, Q195L, Q235

4. Origin of China

5. Package: export seaworthy packing

6. Galvanized or zinc

7. coil weight: 100kg-1000kg /coil

8. around 25 tons can be loaded in 1x20'FCL.

9. slit edge or mill edge.

10. Any third party inspection can accept.

- Q:I help people pull the line, to climb the ceiling, but the ceiling of the light steel looks thin, you can climb up? Afraid! I am now 120 pounds.

- No, gypsum board is too brittle easy to rotten

- Q:There are several specifications for light steel keel with household ceiling

- Wall steel ceiling keel specifications and information decoration materials Light steel keel wall materials are 50, 75, 100, 150 and several other Light steel keel thickness ranging from 0.4mm to 2.0mm. Under normal circumstances, the use of paper gypsum ceiling when most people will choose light steel keel, thin gypsum board using Pu keel, gypsum thick to use thick keel. There are two kinds of galvanized galvanized, one is hot galvanized, one is cold galvanized. Hot galvanized prices are high and cold galvanized prices are low. The ceiling keel consists of the keel (main keel), the cover keel (auxiliary keel) and various accessories. D38 (UC38), D50 (UC50) and D60 (UC60) three series. D38 for hanging point spacing 900-1200 mm not on the ceiling, D50 for hanging point spacing 900-1200 mm Master ceiling, D60 for hanging point spacing 1500 mm Master heavier ceiling, U50, U60 for the cover keel, it With the use of keel. The wall keel consists of horizontal keel, vertical keel and cross brace and various accessories. There are four series of Q50 (C50), Q75 (C75), Q100 (C100) and Q150 (C150) The width of the light steel keel is often used to refer to the keel model, such as the width of 50mm keel is called the 50 keel. Light steel keel side of the high known as the keel side of the high. Keel length is divided into 3 meters, 4 meters two. Keel each price between 12-20 yuan. Paper gypsum board per standard 2400 mm × 1200 mm) price between 22-30 yuan. Plus auxiliary materials costs and labor costs, the general light steel keel partition wall decoration price between 90 to 150 yuan per square meter. There are T line, C-shaped, U-shaped keel and so on.

- Q:Light steel keel paper gypsum board ceiling construction process

- Operating conditions 1. Construction of the structure should be in the cast-in-place concrete floor or prefabricated concrete floor slab, according to the requirements of the radio, according to the embedded φ6 ~ φ10 reinforced mixed boom, shot without the requirements of the arrangement of large keel location embedded steel hanging Rod, the general spacing of why 900 ~ 1200mm. 2. When the wall of the ceiling room for the brick masonry, the elevation should be in the ceiling along the walls and columns around the masonry embedded wood preservative, along the wall spacing 900 ~ 1200mm, the column should not be buried on each side More than two pieces of wood. 3. Install the roof of the various pipelines and ventilation ducts, to determine the light, ventilation and a variety of exposed mouth position. 4. All kinds of materials all ready to prepare. 5. Ceiling cover panel should be installed before the wall, wet operation project. 6. Take the roof construction platform. 7. Light steel skeleton roof in a large area before the construction, should do the model between the roof of the crown, lamp, vents of the tectonic treatment, block and fixed method should be tested and approved by the approved before the big Area construction.

- Q:Office building silicon calcium board ceiling, the actual construction practices: light steel keel spacing 1000mm, small keel spacing 600mm meet the requirements

- 5, the installation of sub-keel 1> has been played by a good sub-keel sub-line, card sub-keel hanging pendant. 2> hanging sub-keel: according to the provisions of the provisions of the keel spacing, the sub-keel hanging hanging on the main keel, the design requirements, the general spacing of 500mm-600mm. 3> When the length of the keel to be a number of continuation of a long time, with the keel connection, hanging in the keel at the same time the connection, straighten the fixed. ?Install the cover panel, the installation of the panel before the end of the terminal equipment must be located on the ground and the various pipeline inspection and acceptance, before allowing the installation of the panel. Cover plate and light steel keel fixed method is: Light steel keel skeleton after acceptance, began to install the first layer of cement fiberboard. First in accordance with the room space on the cement fiber board layout, layout is not allowed to appear below 100mm slats. After the completion of the version, according to the layout placed cement fiber board, and with self-tapping wire fixed firmly. Self-tapping screw spacing of 150-170mm. After the completion of the first layer of cement fiberboard, should check the flatness of the allowable error should be controlled within 3mm. The first layer of cement fiberboard after the acceptance of the installation has been compressed composite panels, the installation of the use of adhesive method, the installation of the first two sides and then the middle.

- Q:Ceiling twenty square meters need light steel keel how many roots

- Light steel keel ceiling material ratio does not have a standard number, generally according to the shape of the room, height related.

- Q:Light steel keel ceiling one square meter how much money

- 1, installed boom When the floor is a prefabricated board, the hoisting hooks of the suspension boom are embedded in the slit, as long as the upper end of the boom can be bent through the hook hole. When the floor is a cast-in-place plate, it should first release the position of the embedded parts at the bottom of the floor. Use the nail to fix the embedded parts to the bottom of the floor, and bend the upper ends of the boom through the rings of the embedded parts Can be. 2, loaded big keel The large keel vertical hanging pieces, such as a number of sets of dog keel, the big keel handed up, so that the lower end of the boom into the large keel vertical hanging pieces on the hole, plus nuts initially screwed. According to the ceiling of the room in the cave from the arch height (generally take the room to ask the short span of 2: 0), calculate the big keel hanging point at the arch value, twist the nut so that the big keel arch arch, after adjustment , The big keel vertical hanging pieces fastened. 3, installed keel Will be in the keel vertical hanging pieces, such as the number on the big keel, the dragon handed up, so that the keel buckle in the vertical hanging parts of the keel. If the keel intersects with the brace, the keel is placed on the middle keel and the cross brace is in the middle of the keel. Light steel keel ceiling price and construction steps on the finished, you all understand it? For light steel keel ceiling price you can according to their own needs to buy.

- Q:Light steel keel ceiling installation detailed process

- Light steel keel: With the level of the room in each corner of the wall to copy the level of the point, pop the horizontal line, with the amount of water to the ceiling design height plus a layer of thickness, with powder line along the column pop-up line, that is, Down line. At the same time, according to the ceiling plan in the concrete roof pops up the position of the main keel, the main keel should be from the center of the ceiling to the two points, the maximum spacing of 1000mm, and marked the boom of the keel should be from the ceiling to the two points, and marked the fixed point of the boom, The fixed point spacing of the boom is 900-1000mm. If the fixed point of the beam and pipe is larger than the design and procedure requirements, the fixed point of the boom should be increased.

- Q:Light steel keel how to do secondary ceiling

- Secondary ceiling local use of wood core board structure, hanging hanging wooden core board structure can do two ceiling. Any light steel keel ceiling of the multi-level ceiling and complex modeling, multi-use wood core board and light steel keel convergence.

- Q:What is the general ceiling of indoor ceiling?

- Upstairs copy of the good. Really quite detailed. That I also talk about it. Light steel keel wood keel aluminum buckle plate steel plate plaster board sauna board

- Q:Would like to ask about the difference between the two and the construction process, which also a cheaper ceiling ah?

- The difference is simple, Use the wood to do keel cheap, but not strong; with Cyclobalanopsis keel firm, really expensive. In fact, the wood is not so strong. Qinggang keel is also not where you go.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Sizes For Lipped Channel/steel Frame/c Shape Channel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords