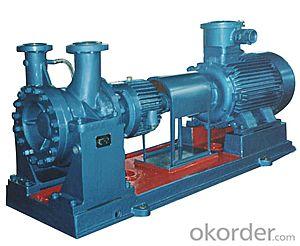

Single Stage Single Suction Centrifugal Oil Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Description

Type AY Series Single Stage Single Suction Centrifugal Oil Pump is a new product designed on the base of old type Y oil pump which is suitable for renewing equipment with the aim of saving energy. It is used for petroleum refinery, petrochemical, chemical industry and other petroleum, liquefied petroleum gas and other mediums which are inflammable, explosive, toxic, high temperature and high pressure without solid particles.

Performance range

Capacity:2.3~600m3/h

Head:30~603m

Temperature:t=-45℃~+420℃

Instruction of pump type

For example:

1:250AYS80

250—Suction nozzle diameter (mm)

A:First reform

Y: Centrifugal oil pump

S:First stage impeller is double-suction

80: Head of single stage (m)

2:80AY100X2B

80:Suction nozzle diameter (mm)

A:First reform

Y: Centrifugal oil pump

100:Head of single stage (m)

2: Stage number

B:Impeller cutting code

Construction:

The construction of oil pump type AY is divided into eight kind single-stage and single-suction overhung, double-stage and single-suction overhung, single-stage and double-suction overhung, single-stage and double-suction with two ends supporting, double-stage and double-suction with two ends supporting, single-stage and double-suction with two ends supporting,multi-stage and ring section.

The single and double stage pump casing is installed horizontally with supported on the center line. The suction and discharge nozzle flanges are cast together on the pump casing and vertical upwards. The stuffing boxes and pump cover are cast together which can be installed with soft packing seal and mechanical seals such as balancing bellow and series. The water-cooled chamber jacket, which can be selected ,is installed outside of shaft sealing chamber the water cooled chamber will be installed only when required by customers or when the medium is water with temperature more the 66℃ and hydrocarbon compound with temperature more than 120℃.

A journal ball bearing and thrust bearing arranged back-to-back are installed on the bearing housing. The bearings are lubricated by flinger with thin oil. Cooling fins are cast outside of bearing housing which can be cooled by air(temperature is less than 120℃). The bearing housing also can be cooled by water(temperature is 120℃ to 420℃)

The pumps are driven directly by driver through the membrane coupling. View from motor end, the rotating direction is anticlockwise.

- Q:Dear friends, please let me know in most of the power plants recirculation line and balance leak off lines are provided for boiler feed water pumps and those lines are connected to Deaerator. Why?

- The feed pumps for most power plants are multistage centrifugal pumps. They have a minimum flow requirement or the balancing forces of the various impellers are lost and the pump is damaged. A recirculation line permits a minimum flow to be maintained at all times. It goes back to the deaerator so the boiler feedwater is not lost. Note: many of these pumps have the recycle automated so it is only in operation at very low flow rates. The leak off from the balancing line is recycled for the same reason.

- Q:Not sure of the year model but think it is a 1991 to 1995 Jayco 2500FS bumper pull trailer. I bought it to put on a deer lease. One of the previous owners had taken out the water tank which I plan on replacing. I can't find the water pump to see if I need to replace it as well. Also, if you know about how the pump knows when to kick on i.e. pressure switch, push button or what. I know I could take it to have repairs done but enjoy the diy thing. I am in the process of finding out the exact year model as well. Thanks!

- having had many travel trailers the water pump is usually in a cabinet or under a bed or couch with a lot of plastic water lines near where you screw the water hose into the side of the trailer. and they are usually a preset psi from the factory so that is usually nothing to have to worry about and most have an on off switch located in the traier by the kitchen sink.And if the hot water heater is no good look into a tankless water heater it will save you money in the long run but initially you have to have a vent installed up through the roof away from a roof air vent. Another suggestion everytime you move a travel trailer they get the crap pounded out of them and someone needs to go up on the roof with a ladder and/or a plank that goes across the width so there is no weight standing on a roof to make dents or pop seams. Use some plastic stuff like plasticote available at wal mart after you move the trailer and set it up go up and make sure to double coat any of the seams that need it. I crank the heat up inside the trailer and do a double coat the heat rising will put a skin on the plasticote in a few hours instead of 12 or more. and the double coat gets any cracks missed the first time around. After that check it once a year if the trailer stays there.

- Q:I have a deep tropical fish tank, my three in one pump is 15 watts, if I put it in the middle of the active oxygen bubbling tank can function, everything is normal, but not very good filtering, can not clean up the garbage at the bottom of the tank. So they put the pump a little deeper, but at this time the pump does not bubble, the oxygen supply in the pipe there is water, atmospheric pressure can not enter, but still can pump water filter, so that the pump itself harmful? Will the pump burn out? This question is very important to me. Please help my brothers and sisters downstairs. I will thank you for my dear tropical fish

- First tell you the pump not bad, just can't carry oxygen rinse, now he is equivalent to a 2 in a filter of the submersible pump, without any damage to the pump itself, three in one pump is actually in the 2 water outlet and air pipe, pressure by fluid flow is the principle of position the smaller the air drag, now a large pressure, oxygen loss of function, but the pump itself, his work without any change, so do not burn, rest assured it

- Q:We had a leak in our car and took it to get checked out. They said it is the water pump. Also that it would be around $650 to replace. I know nothing about cars. Is this necessary? and does the cost sound about right? We are going on a 3 hour trip one way this weekend. Would it need to be done before then? thanks guys!

- on cars with water pumps that run off the timing belt it can be pricey to replace. If its a vehicle that has a water pump running off the accessory belt it shouldn't be to much unless its a BMW or foreign. state what kind of car its for it could help us answer. also do the water pump before the trip, if its really bad then getting stranded will cost you alot more.

- Q:My old pump burned up so i recently replaced it (with a refurbished pump) I have new pipe to the pump, new tank. my pump is a 1/2 hp 230v pump, I also replaced the control box. With my pump plugged in and the water coming straight out of the pipe bypassing the tank when I turn the power on I will get water for a minute or so then I won't get water for a minute. This will keep happening. I have checked the switch and when I quit getting water there is still power going to the pump. any suggestions or ideas? bad wiring or bad pump?...I know that there is water in thew well, the pump is located at 100 ft of a 115 ft well and i can see the water level about 10 ft underground.

- A good pump would pump water continuously without being hooked to the tank. You say the power is still going to the pump when it quits but you didn't say if it is getting the proper voltage and you didn't say if the pump is still running but just not pumping. If it's still running then try raising the pump some. If it's not running then I'd suspect the thermal protector switch so you'd need a new pump. Are you sure there's a full 230V going to the pump? Sometimes ants like to get in the electrical pressure switch and get in between one or more of the contacts.

- Q:I have a 1999 Chrysler LHS. Recently, the water pump started leaking and it ruined the timing belt. I brought it to a mechanic that I've never used before, so I have no idea how reliable they are. They now told me that my brake lines blew. Can the leaking water pump also cause brake lines to rot?

- Very doubtful. Even getting anti-freeze on a timing belt should not ruin that. If you had no idea when it was last changed, and it showed signs of cracking, then it would be a good idea to replace it. Make sure to retain mileage records of when it was done. Did he specifically say the brake line rot was related? There are metal lines leading out to the suspension points and then rubber reinforced hoses for the last foot to 18 inches to the backing plate/brake caliper. Usually the rubber line is the first to go. The metal lines can last many decades.

- Q:I have 2004 Chevy Trailblazer V8 4x4 that the water pump went out on. Does anyone know how long it takes to change it and where it is located? The dealer wants $750.00 to fix it. I really don't want to get riped off.

- Depends on the engine. For the 4.2L (6 cylinder), the water pump (part # 24576952) costs $107.22. Labor time is 3.1 hours. There is also about 2 gallons of Dexcool coolant, about $30. For the 5.3L (V8), the water pump (part # 89017439) costs $231.42. Labor time is 3.6 hours. Also, 2 gallons Dexcool, $30. For the 4.2L, $750 is definately too much. For the V8, unless the labor rate at that dealer is about $135 per hour, $750 is still too high. I worked for a Chevy dealer for 3 1/2 years, and now own an independant shop. I recommend you find a good honest independant, and stick with them. I would charge just over $300 for the 4.2, about $500 for the V8. Now that you know the price of the parts and the labor time, you can make some calls and get a good estimate. Your first question should be what their labor rate is. Then tell them what you need done. Good luck.

- Q:here is the problem with my water pump control switch settings. the water is being used, runs dry and stays off for sometimes 3 minutes or so.i realize the springs control the cut in and cut out. do i need to make the spring more compressed to make the pump come on sooner? or do i need to make the spring looser to make the switch come on sooner?when i read/hear about adjusting the cut in. the answers seem vague because i do not know the perspecitve of the spring.does compressing the spring make the swith flip easier? or does compressing the spring make the switch harder to flip on?i installed a new 30/50 switch today. My air tank was at 50 or so PSI. but i dropped it to about 30. is the goeal to make the entire full system 50 pounds? because after my pump cycles i get about 70 psi!!!

- The problem lies with the new 30/50 switch. With Your pressure tank empty of water, set the air pressure at 28psi. What is happening is when the water pressure drops below about 45 psi - the air pressure (50psi) on the bladder is forcing the water out rapidly. Then the pump has to work like cracy to overcome that bladder pressure! Easy Fix. Make sure the tank has no water in it.

- Q:For a Dodge Ram 1500 pick-up. Not taking it to a mechanic.Already got the new pump. Got part of the engine off.Dont exactly have the right tools to make the job go fast but would like some tips on how to make it go faster..

- If you've got the fan off you have the hardest part done on that vehicle,follow the manuals and line the parts up as you remove them.Be sure to put the bolts with the part they belong to and install them in the reverse order you took them off.

- Q:I have an 1982 El Camino 305 small block and am having troubles with determining if it is the gasket or the pump. I can't quite locate a leak, but it seems to centralize from the water pump and drip down the hose to the radiator. After my engine gets hot, which mind you my temp light has never turned on, and I shut of my car steam rolls out from behind my pump. I think it is the pump and please be it so. (Easier and cheaper fix. Replacement with a inexpensive part XP.)

- Pull the oil dip stick if it has little bubbles on it and it is discolored you have a blown head gasket.Then pull your radiator cap when engine is cold, is it full or not? You can not trust what I call idiot lights because they usually come on after the damage is done.You can tell if the water pump is working by letting eng get to normal and grasp the top hose and squeeze it just a little,can you feel water running thru it,if not replace it.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Single Stage Single Suction Centrifugal Oil Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords